Film packing machine for double-component material

A material film and two-component technology, which is applied in packaging, transportation packaging, multiple packages, etc., can solve the problem that two-component materials cannot be separated and packaged, and achieve convenient transportation and use, convenient operation and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

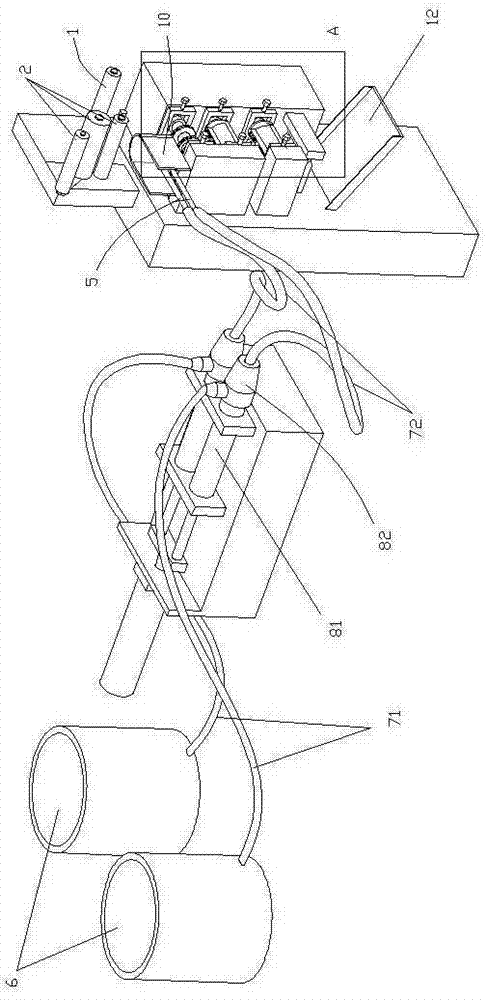

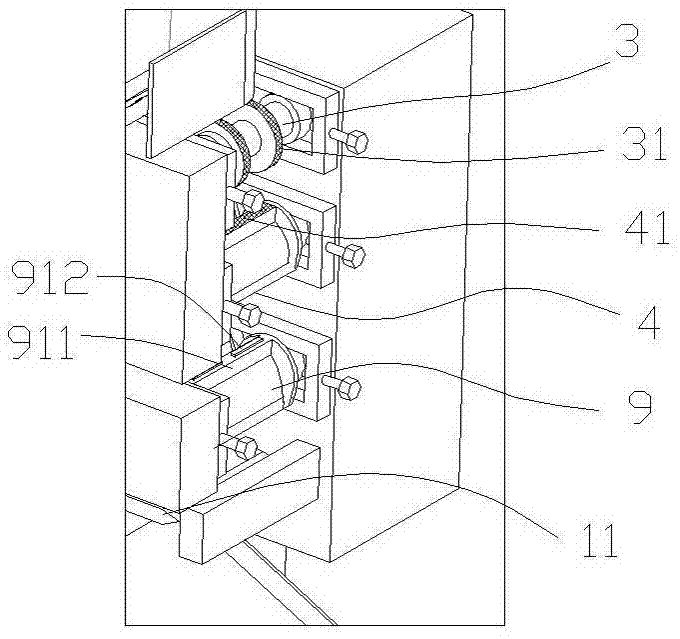

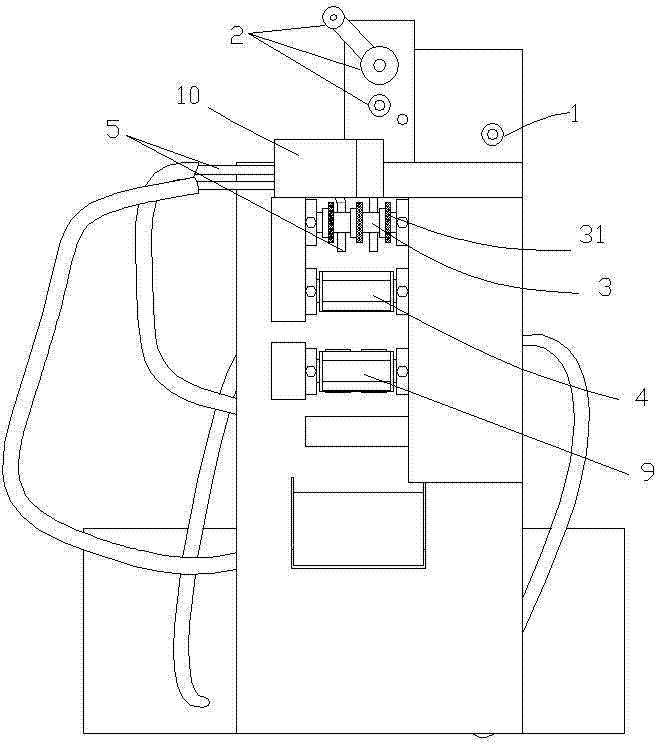

[0024] like figure 1 , figure 2 , image 3 In the shown embodiment, a two-component material film packaging machine includes a film feeding device, a two-component material feeding device, a heat sealing device and a cutting device.

[0025] The film feeding device includes a storage roller 1 for storing film rolls, three guide rollers 2 for guiding the film to advance and a winding mechanism for guiding the film to be wound. The three guide rollers 2 that guide the film travel are distributed alternately between the storage roller 1 and the heat-sealing device so that the film travels downwards. The winding mechanism used to guide the film winding is a transverse U-shaped plate 10, which is located in the longitudinal heat The upper end of the sealing roller 3. Guided by the guide rollers, the film enters the U-shaped plate 10 downwards, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap