Automatic synchronous bottom oil cylinder jacking and lowering device of crawling crane

A crawler crane, automatic synchronization technology, applied in the direction of cranes, transportation and packaging, etc., can solve the problems of large driver manual intervention, inconsistent load pressure, host tipping, etc., to reduce the driver's manual intervention, reduce fatigue, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment, the present invention is further described:

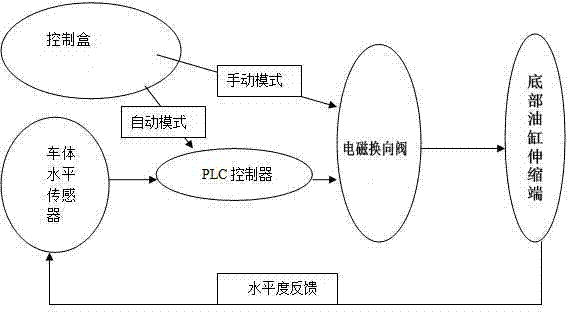

[0019] Such as figure 1 The shown crawler crane bottom oil cylinder automatic synchronous jacking and lowering device includes a control box, which is equipped with a manual operation module and an automatic operation module; an electromagnetic reversing valve is installed on the oil circuit of the bottom oil cylinder of the crane, and The telescopic end of the bottom oil cylinder is also equipped with a vehicle body level sensor; wherein, the manual operation module is directly connected to the electromagnetic reversing valve to control the lifting of the bottom oil cylinder; the automatic operation module is connected to the electromagnetic reversing valve and the vehicle body level sensor at the same time. sensor, and receive the signal from the vehicle body level sensor for automatic control.

[0020] In this embodiment, there are multiple electromagnetic reversing valves, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com