Methods to reduce fiber loss

A technology of optical fiber loss and bare optical fiber, which is applied in the field of optical fiber manufacturing and can solve problems such as inability to effectively reduce optical fiber loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

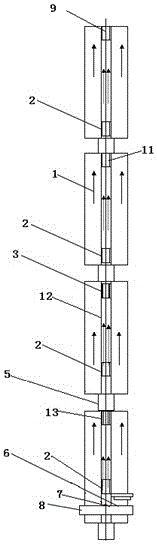

[0015] Combine figure 1 The manufacturing method of the low-loss optical fiber of the present invention will be described.

[0016] After the preform is drawn, the bare optical fiber is obtained, which passes through the cooling system from top to bottom at 1500 m / min, and then is coated to obtain the optical fiber. The cooling system includes four cooling cylinders with a length of 1200mm and connectors between the cooling cylinders. The cooling cylinder is provided with a first pipe for transporting helium and optical fiber movement. The inner diameter of the first pipe is 10mm and the helium flow rate is 4-5L. / min, the intake air temperature is 20±3℃. Cooling water is passed between the cooling cylinder and the first pipe, the flow rate of the chiller is 8L / min, and the cooling water temperature is 17°C. Cooling water and helium flow from bottom to top. Under normal circumstances, each cooling cylinder is equipped with two third pipes that are interference fit with the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com