Anti-rut agent for cool mixing and cool spreading of asphalt road

An anti-rutting agent, road technology, applied in the field of anti-rutting agent, can solve the problems of large performance difference and affecting the performance of the mixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Weigh 1Kg of gravel with a crushing value of 9.5-13.2, 2Kg of crushed stone with a crushing value of 4.75-9.5, and 1Kg of stone chips, and mix them into aggregates;

[0016] (2) Weigh 10% powder anti-stripping agent, 10% mineral powder, 20% polymer rubber powder and 50% sulphoaluminate cement to make a concentrated curing agent, and weigh the yellow concentrated curing Add 60g (1.5%) of the curing agent, put the above aggregate and curing agent into the mixing pot and stir for 30s;

[0017] (3) Weigh 80g (2%) of water, add it into the stirring pot and continue stirring for 30s;

[0018] (4) Weigh 380g (9.5%) of asphalt liquid at room temperature, add it into the mixing pot and continue to stir for 60s, the mixed material can be kneaded without loosening and stirred evenly;

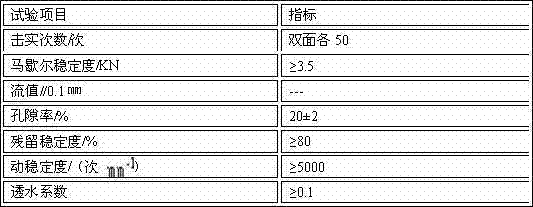

[0019] (5) Make 3 standard Marshall test pieces from the mixed material, weigh 1.3Kg of the mixed material for each test piece, and compact 50 times on both sides;

[0020]...

Embodiment 2

[0024] (1) Weigh 1.1Kg of gravel with a crushing value of 9.5-13.2, 2.2Kg of crushed stone with a crushing value of 4.75-9.5, and 1Kg of stone chips, and mix them into aggregate;

[0025] (2) Weigh 12% powder anti-stripping agent, 15% mineral powder, 25% polymer rubber powder and 65% sulphoaluminate cement to make a concentrated curing agent, and weigh the yellow concentrated curing 75g (1.5%) of the agent, put the above aggregate and curing agent into the mixing pot and stir for 30s;

[0026] (3) Weigh 90g (2%) of water, add it into the stirring pot and continue stirring for 30s;

[0027] (4) Weigh 420g (9.5%) of asphalt liquid at room temperature, add it into the mixing pot and continue to stir for 60s, and the mixed material can be kneaded without loosening and stirred evenly;

[0028] (5) Make 3 standard Marshall test pieces from the mixed material, weigh 1.3Kg of the mixed material for each test piece, and compact 50 times on both sides;

[0029] ...

Embodiment 3

[0033] (1) Weigh 1.25Kg of crushed stones with a crushing value of 9.5-13.2, 2.5Kg of crushed stones with a crushing value of 4.75-9.5, and 1.25Kg of stone chips, and mix them into aggregates;

[0034] (2) Weigh 15% powder anti-stripping agent, 20% mineral powder, 30% polymer rubber powder and 70% sulphoaluminate cement to make a concentrated curing agent, and weigh the yellow curing agent 90g (1.5%), put the above aggregate and curing agent into the stirring pot and stir for 30s;

[0035] (3) Weigh 100g (2%) of water, add it into the stirring pot and continue stirring for 30s;

[0036] (4) Weigh 475g (9.5%) of normal-temperature asphalt liquid, weigh 10g of rock asphalt solution and add it to the normal-temperature asphalt liquid and stir for 2 minutes, then add them into the stirring pot and continue stirring for 60 seconds, and the resulting mixture can be kneaded without loosening;

[0037] (5) Mix 4-6 pots of mixture in this way (too much mixture at one time is not easy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com