A crystal zirconium processing device

A processing device and crystal technology, applied in the field of new crystal zirconium processing devices, can solve the problems of cumbersome, labor-intensive, unreachable temperature, etc., and achieve the effect of high product quality and saving labor and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

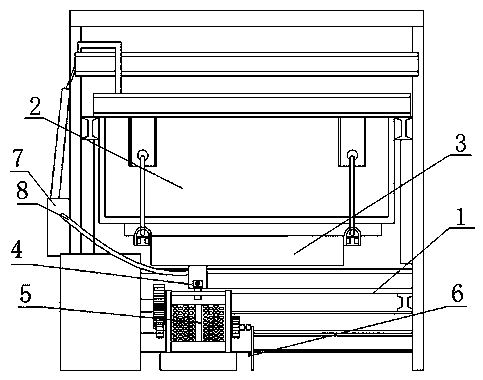

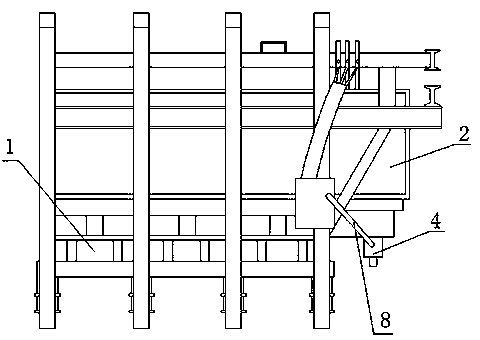

[0010] Such as figure 1 , 2 As shown, a novel crystal zirconium processing device includes a support frame 1, a melting pool 2, a transition device 3, a discharge pipe 4, a mold 5, and a water pipe 6. The support frame 1 is composed of several steel materials, and the support frame 1 A melting pool 2 is placed inside, and a transition device 3 is provided under the melting pool 2. The bottom of the transition device 3 is connected with a discharge pipe 4, and the discharge pipe 4 is connected with the electric box 7 hanging on the left side of the support frame 1 with a wire 8 , on the ground facing the discharge pipe 4, the mold 5 installed on the workbench is placed, and the vertical water pipe 6 on the ground communicates with the axis crossing the mold 5. The support frame 1 is constructed and welded by several steel materials. Said melting pool 2 is provided with chemical material area, air bubble elimination area and homogenization area. The melting pool 2 is powered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com