Composite carbon nanomaterial and preparation method thereof

A carbon nanomaterial and nanomaterial technology, applied in the field of composite carbon nanomaterials and their preparation, can solve problems such as increasing the resistance of composite materials, and achieve the effect of tight bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

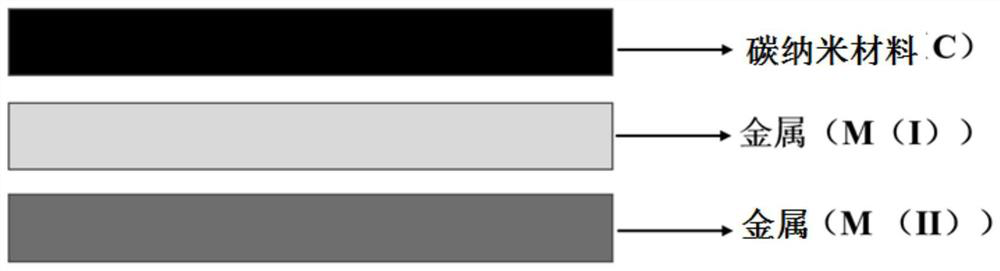

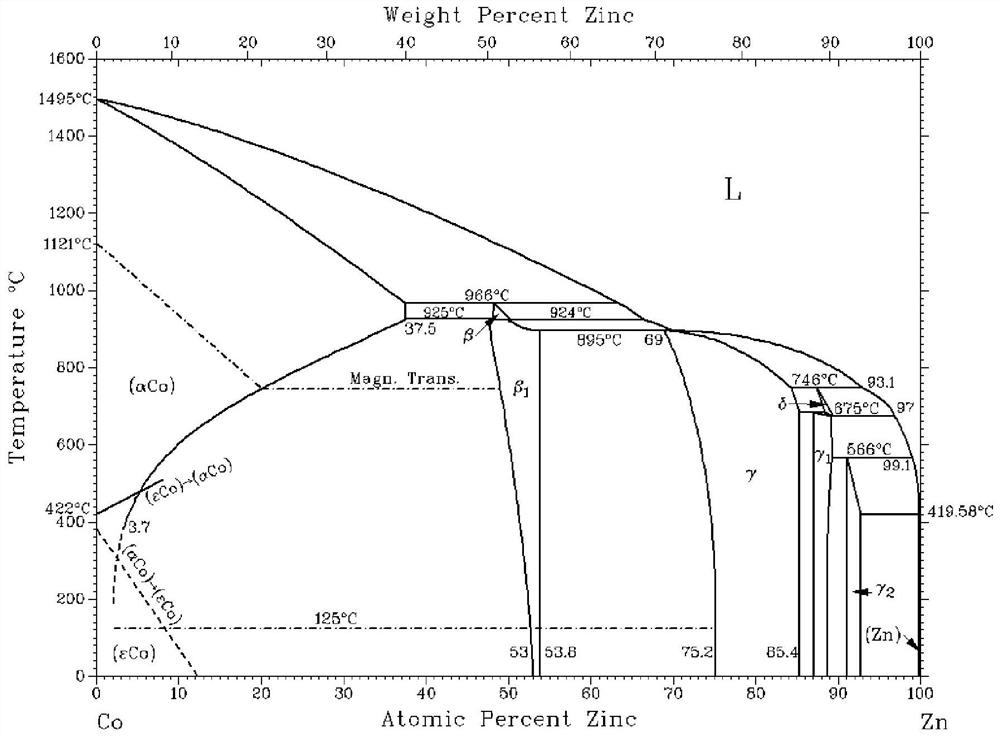

[0030] S1: A carbon nanotube film with a thickness of 40-50 μm prepared by the gas-phase floating catalytic method;

[0031] S2: Spread the zinc foil on the experimental bench, then spread the cobalt foil on the surface of the zinc foil, and then spread the carbon nanotube film on the surface of the cobalt foil;

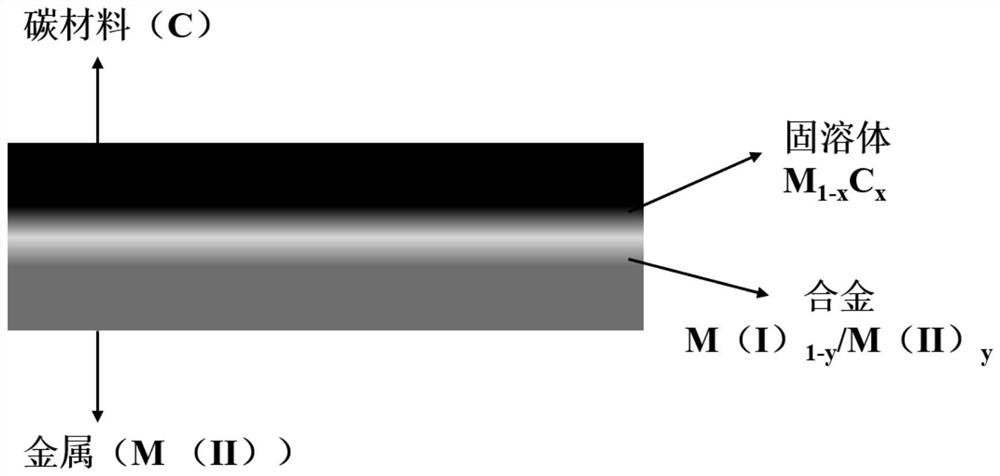

[0032] S3: Put the laminated material in a vacuum hot-press furnace, evacuate until the pressure in the furnace is less than 10Pa, pressurize to 5MPa in two directions, slowly raise the temperature of the furnace to 300°C and keep it for 0.5 hours, and the carbon nanotube film-cobalt is obtained -Zinc triple layer composite. The carbon nanotube film and metal cobalt are connected by cobalt-carbon solid solution, and the contact part of zinc foil and cobalt foil forms a zinc-cobalt alloy, so that metal cobalt and metal zinc are closely connected together, see image 3 .

Embodiment 2

[0034] S1: A graphene film with a thickness of 40-60 μm prepared by chemical vapor deposition;

[0035] S2: Spread the copper foil on the test bench, then spread the iron foil on the surface of the copper foil, and then spread the graphene film on the surface of the iron foil;

[0036] S3: Put the laminated material in a vacuum hot-press furnace, evacuate until the pressure in the furnace is less than 10Pa, pressurize to 10Mpa in two directions, slowly raise the temperature of the furnace to 850°C and keep it for 1 hour, and the graphene film-iron- Copper three-layer composite. The carbon nanotube film and metal iron are connected by iron-carbon solid solution, and the contact part of iron foil and copper foil forms an iron-copper alloy, so that metal iron and metal copper are closely connected together, see Figure 4 .

Embodiment 3

[0038] S1: A carbon nanotube film with a thickness of 50 μm prepared by using a carbon nanotube dispersion;

[0039] S2: Spread the tin foil on the experimental bench, then spread the iron foil on the surface of the tin foil, and then spread the carbon nanotube film on the surface of the iron foil;

[0040] S3: Put the laminated material in a vacuum hot-press furnace, evacuate until the pressure in the furnace is less than 10Pa, pressurize to 10MPa in two directions, slowly raise the temperature of the furnace to 200°C and keep it for 2 hours, and the carbon nanotube film-iron -Tin three-layer composite. The carbon nanotube film and metal iron are connected by iron-carbon solid solution, and the contact part of iron foil and tin foil forms an iron-copper alloy, so that metal iron and metal tin are closely connected together, see Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com