Metal-ceramic seamless bonding process

A metal-ceramic, seamless bonding technology, which is applied in ceramic forming machines, techniques for producing decorative surface effects, decorative arts, etc., can solve problems such as small joints, weak firmness, and water accumulation in the joint layer, and achieve The effect of improving appearance, retaining beauty, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

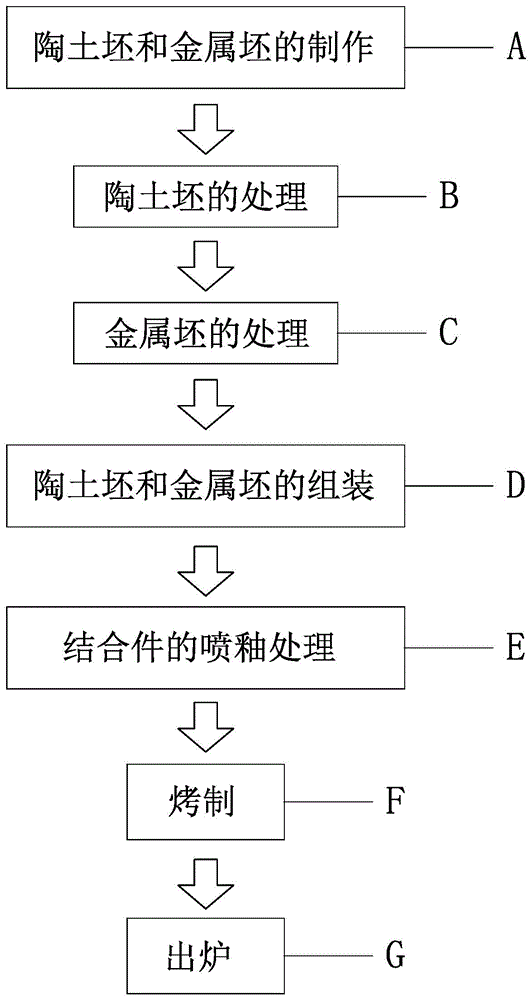

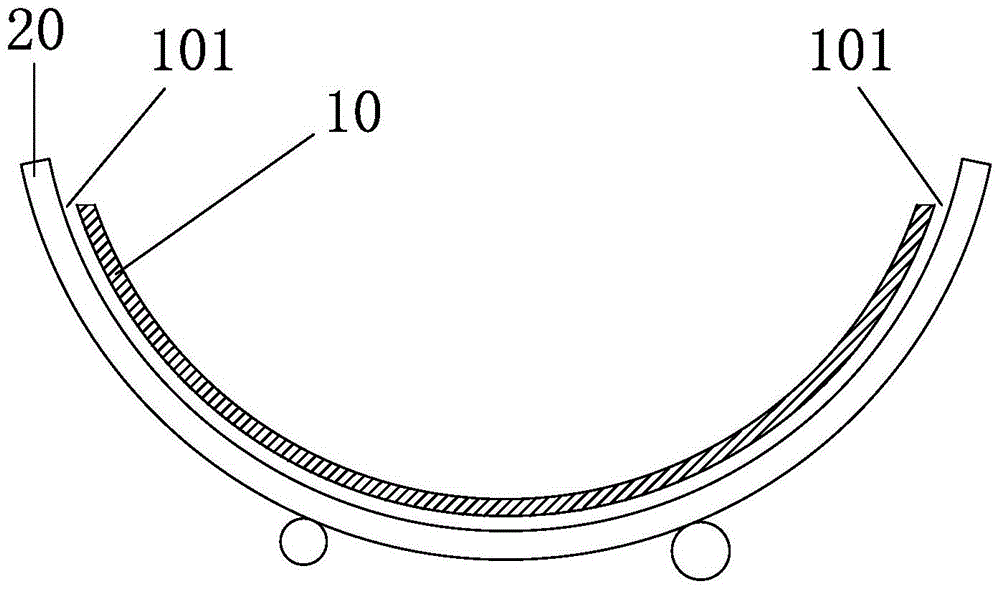

[0029] refer to figure 1 As shown, in this embodiment, a single-layer cermet seamless bonding process is disclosed, through which a bowl containing a single-layer metal fitting is produced, and the material of the metal blank 10 is gold, silver, copper, platinum, Any one of palladium, iridium, nickel, steel, and iron. In the present embodiment, the material of the metal blank 10 is gold, and the seamless bonding process of the single-layer cermet comprises the following steps:

[0030] A. Production of clay and metal billets: refer to figure 2 As shown, the clay blank 20 is produced according to the requirements, and the actual parameters are measured after the clay blank 20 is shaped, and the metal blank 10 is produced according to the obtained actual parameters. In this embodiment, since the metal blank 10 needs to be arranged in the clay blank 20 , the volume of metal billet 10 should be slightly smaller than the volume of clay billet 20, so as to ensure that the matching...

Embodiment 2

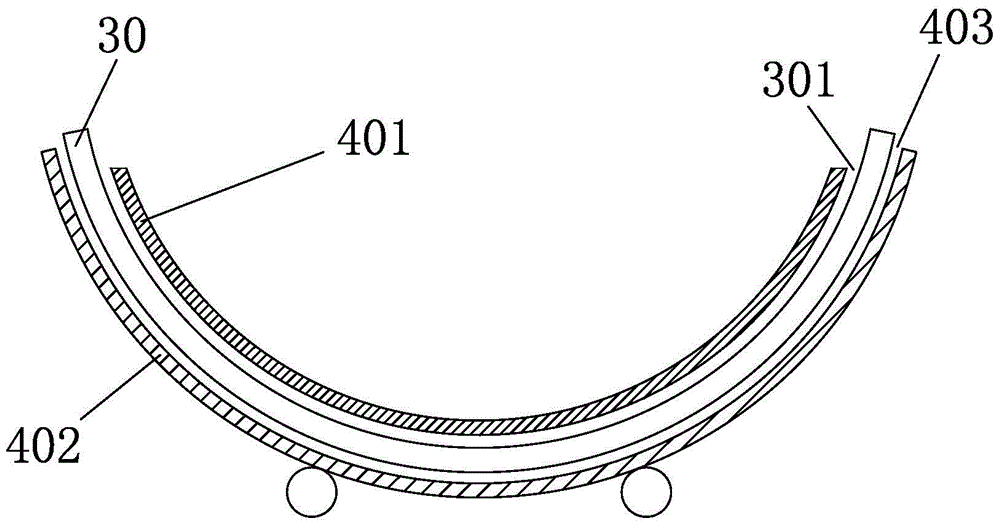

[0039] refer to figure 1 and combine image 3 As shown, in this embodiment, a double-layer metal-ceramic bond is disclosed, and the metal in the double-layer metal-ceramic bond is silver. The manufacturing process of the double-layer metal-ceramic bond includes the following steps:

[0040] A. Production of clay and metal billets: refer to image 3 As shown, according to the requirements, a clay blank 30 is produced, and the actual parameters are measured after the clay blank 30 is finalized, and a metal blank is produced according to the obtained actual parameters. In this embodiment, there are two metal blanks, and the inner one is the first The metal blank 401, the outer one is the second metal blank 402, the volume of the second metal blank 402 is slightly larger than the first metal blank 401, but the volume is smaller than the volume of the clay blank 30, ensuring that the first metal blank 401 and the second metal blank 402 The matching degree with the clay brick 30 i...

Embodiment 3

[0050] refer to Figure 4 As shown, in this embodiment, an ornamental metal-ceramic joint is disclosed, and the metal in the decorative metal-ceramic joint is platinum. The manufacturing process of the decorative metal-ceramic joint includes the following steps:

[0051] A. Production of clay and metal billets: refer to Figure 4 Shown, make pottery adobe 50 according to requirement, this pottery adobe 50 can be various shapes, for example Figure 4 Heart-shaped as shown, and after shaping the clay blank 50, a metal blank 60 can be produced. In this embodiment, the metal blank 60 has an elliptical structure, and it is ensured that the size of the clay blank 50 and the metal blank 60 are suitable to reduce scrap rate and improve product stability;

[0052] In addition, the shape of the clay brick and the metal blank can also be other shapes, such as Figure 5 Among them, the clay blank 50 is in the shape of a cuboid, while the metal blank 60 is in the shape of a pentagon;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com