Starlike anti-shearing polyacrylamide for fracturing fluid and preparation method of starlike anti-shearing polyacrylamide

A technology of polyacrylamide and acrylamide, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., to achieve the effects of mild conditions, excellent temperature resistance and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

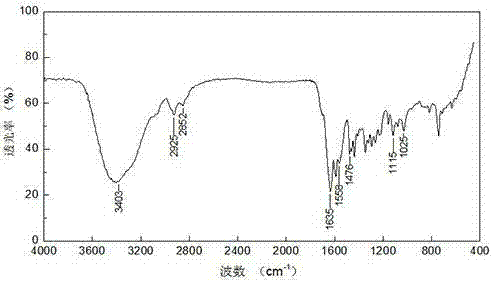

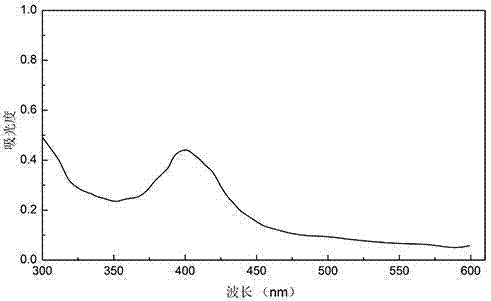

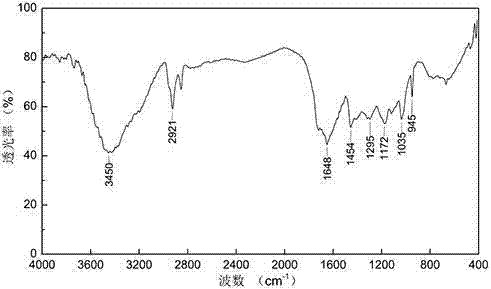

Image

Examples

Embodiment 1

[0044] (1) Preparation of thioxanthone-modified dendritic polyamide-amine water-soluble initiator

[0045] (a) Dissolve 0.05mol (8g) of thiosalicylic acid in 75mL of concentrated sulfuric acid, stir well for 10min, then slowly add 0.25mol (22g) of phenol, dropwise for 30min, and continue stirring at room temperature for 1h , and then heated to 80 ° C for 2 h, and then left at room temperature overnight. Add the reaction solution dropwise to 750mL boiling water, continue to boil for 30min after the addition, cool and filter to obtain the initial product, which is recrystallized in a mixed solution of 1,4-dioxane / water with a volume ratio of 4:1 , to obtain 2-hydroxythioxanthone.

[0046] (b) Add 0.01mol (2.28g) of 2-hydroxythioxanthone, 5g of anhydrous potassium carbonate, and 15mL of epichlorohydrin into 20mL of toluene, react at 80°C for 12h, and then reflux at 135°C for 12h . After the reaction, use a rotary evaporator to remove excess epichlorohydrin and solvent, dissolv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com