A new type of cleaning device for flats of spinning and carding machines

A technology of machine cover plate flower and cleaning device, which is applied in the direction of deburring device, textile and paper making, fiber processing, etc., and can solve the problems of loss, hacksaw blade damage, cleaning is not clean enough, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

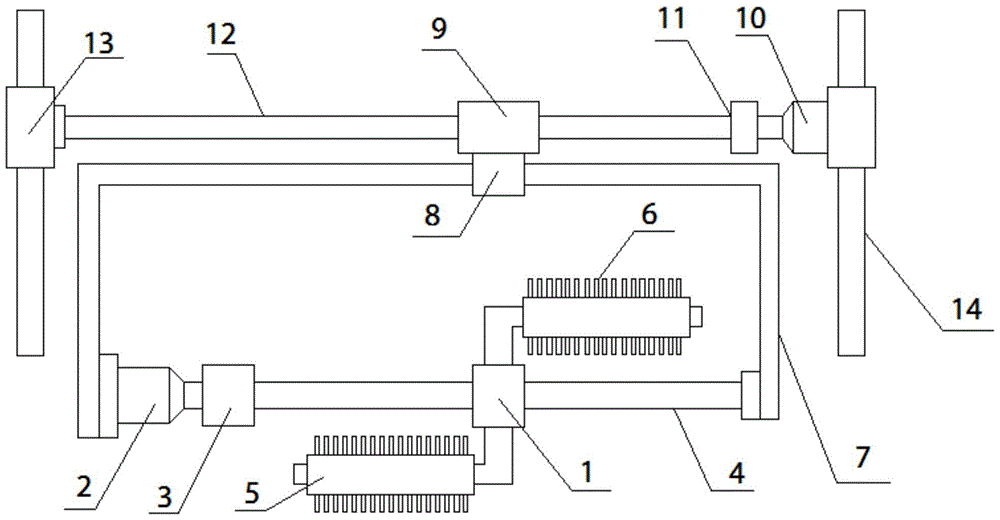

[0011] Such as figure 1 A new type of spinning and carding machine flat flower cleaning device shown includes a "Z" shaped cleaning bracket 1, a cleaning sleeve 5, a first motor 2 and a rotating shaft 4, and the first motor 2 is fixedly connected to the One side of the translation bracket 7, the first motor 2 is horizontally connected to one end of the rotation shaft 4, and the other end of the rotation shaft 4 is movably connected to the other side of the translation bracket 7, and the "Z" shape is clean The bracket 1 is set on the rotating shaft 4, and the front and rear ends of the "Z"-shaped cleaning bracket 1 are respectively set with a cleaning sleeve 5, and the outer side of the cleaning sleeve 5 is wrapped with an elastic card clothing 6. The translation bracket 7 is connected to the translation mechanism through the connecting block 8, and the translation mechanism is connected to the lifting mechanism. When it is necessary to clean the cover plate of the spinning ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com