Selvage of woven fabric with impression and performance like knitted fabric and production method of selvage

A technology of knitted fabrics and woven fabrics, which is applied in the direction of fabrics, textiles, and trimming, etc. It can solve the problems of creases on the cloth surface, messy loops, and differences in the square meter weight of the edges, so as to increase the resistance to external forces and achieve smoothness and stability. Consistent, stable and consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The appearance and performance of this embodiment is like the selvedge of a woven fabric of a knitted fabric, including warp and weft. The warp and weft are interwoven with light and heavy flat or variable light and heavy flat weaves to form a selvedge, and the width of the selvage is set to 1.3cm~ 3cm, the total tightness of the selvedge is 20%~35% larger than the cloth body, the warp yarn is made of pure cotton yarn or blended cotton yarn or chemical fiber filament, and the weft yarn is made of at least one hard yarn and at least one Elastic yarns are alternately arranged according to a predetermined arrangement, wherein the special number of pure cotton yarn or blended cotton yarn is 14tex~59tex, and the denier number of chemical fiber filament is 75D~450D. The elastic yarn can be high elastic yarn or Filament core-spun yarn, the denier number is 100D~600D; the elastic yarn can also use cotton-spandex core-spun yarn or blended cotton-type spandex core-spun yarn, the d...

Embodiment 2

[0033] This embodiment is a method for producing a selvedge of a woven fabric with the appearance and performance as described in Embodiment 1. The method includes: when the number of heald frames configured by the loom is greater than 2 pages of cloth body weave cycles and When the above is above, the selvedge can be woven separately; that is, when the loom is configured with 12 heald frames or more, the weaving cycle is 10, the selvedge width is set to 1.3cm~3cm, the drawing-in method 1.1.2.2 is adopted, and the selvage is threaded The number of reed penetrations is at least 5 yarns per reed (at least 4 yarns per reed is used for the ground weave), preferably 5 yarns per reed, that is, the number of reeds at the edge of the cloth is one or more than the cloth body, and the weave adopts 4 / 4 warps or 5 / 5 warps, preferably 5 / 5 warps; when the loom is equipped with 14 pages of heald frames or more, the weaving cycle is 12, the selvedge width is set to 1.3cm~3cm, and the heald A...

Embodiment 3

[0035] This embodiment is also a method for producing a selvedge of a woven fabric having the appearance and performance as a knitted fabric as described in Embodiment 1, the method comprising:

[0036] When the number of heald frames configured on the loom is greater than 1 page of cloth body weave cycle or equal to the number of cloth body weave cycles, the independent selvage cannot be woven, and the heald frames of the cloth body need to be used to weave the selvage edge. This method includes ground weave The threading method can be adopted, and the threading method of the selvage weave can be preferentially used in the opposite or different threading method to the ground weave to form a pattern symmetrical with the cloth body to form a cross resistance. This method can not only achieve the effect of saving healds, but also It can help clear opening, facilitate weaving and effectively reduce weft shrinkage.

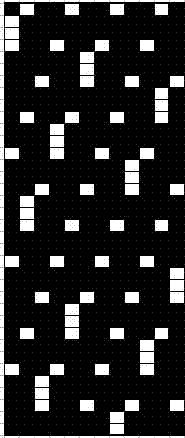

[0037] Such as figure 1 , the figure is the weave cycle diagram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com