Sand washing concentric tube for low-pressure absorption well and assembling method of sand washing concentric tube

An assembly method and lost well technology, applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problems of unusable oil pipes, difficult processing technology, unreliable technology, etc., achieve reliable sealing, improve sand washing efficiency, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

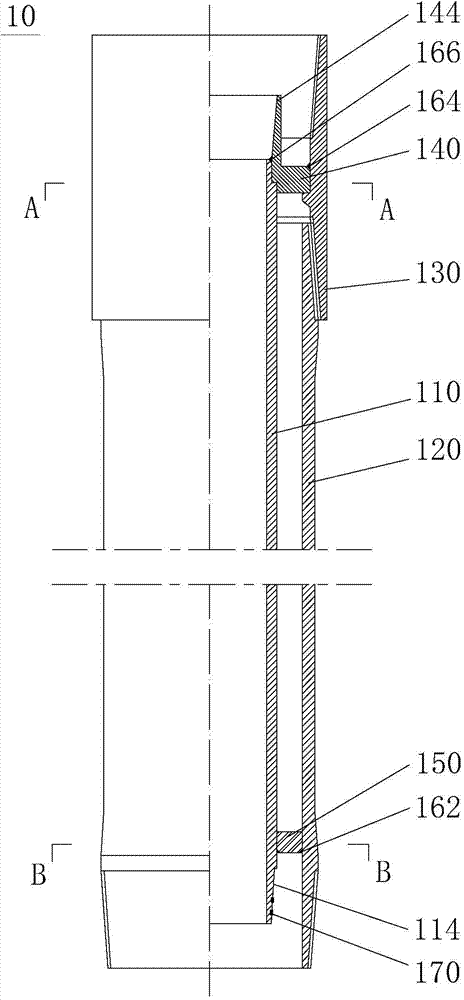

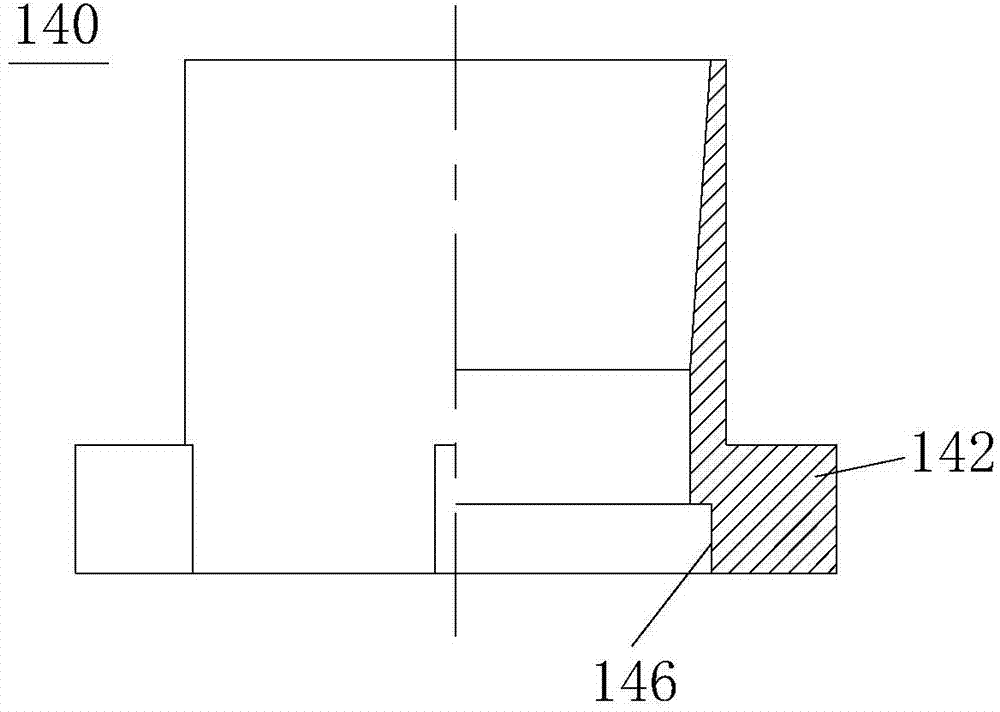

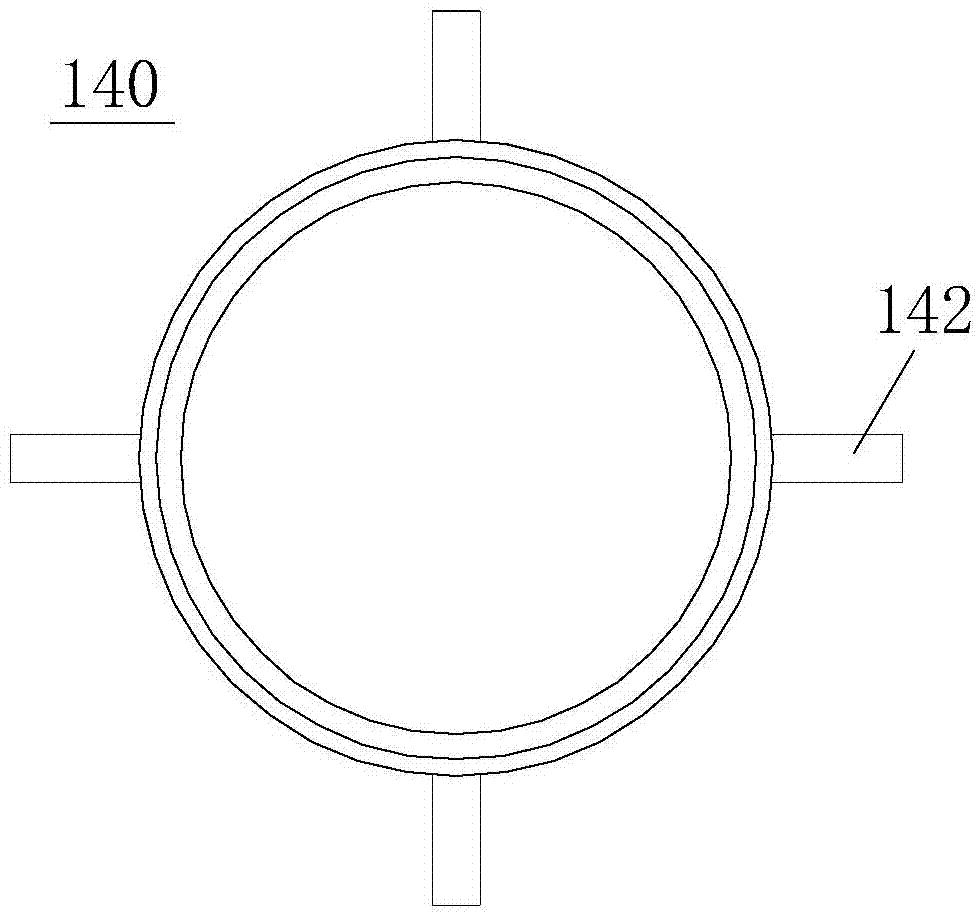

[0041] see figure 1 As shown, a sand washing concentric pipe 10 for low-pressure leakage wells includes an inner sand washing pipe 110 and an outer sand washing pipe 120, the inner sand washing pipe 110 is placed in the outer sand washing pipe 120, and the two are spaced apart An annular cavity is formed. The special-shaped collar 130 is set and fixed on the upper end of the outer sand washing pipe 120, and a through hole is arranged on the upper sealing joint 140. In this embodiment, the through hole is set at the center, and the upper sealing joint 140 is fixed on the inner sand washing pipe 110 through the through hole. upper end.

[0042] Please combine figure 2 and image 3 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com