Method for increasing construction space under invert trestle of single track railway tunnel

A trestle and steel trestle technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of small space, difficulty in scientific and effective organization of single-track tunnel construction procedures, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

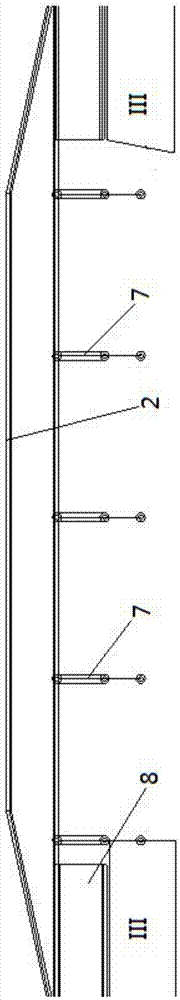

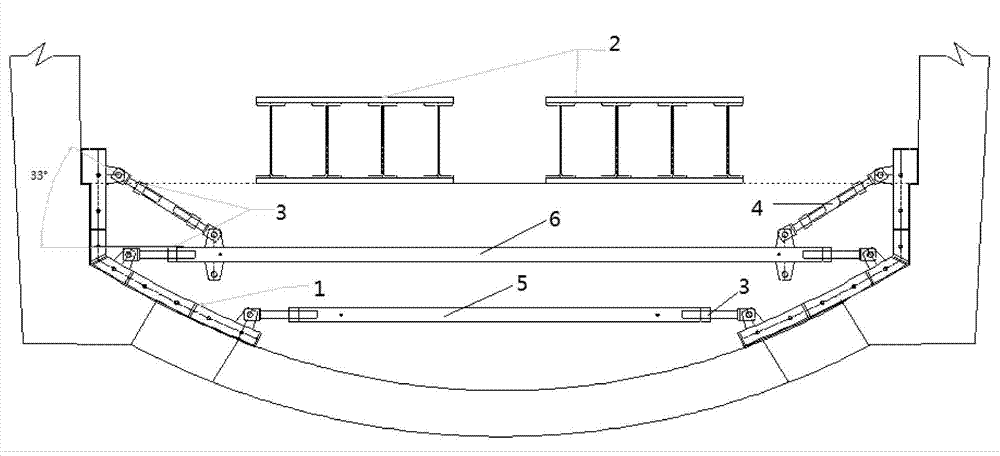

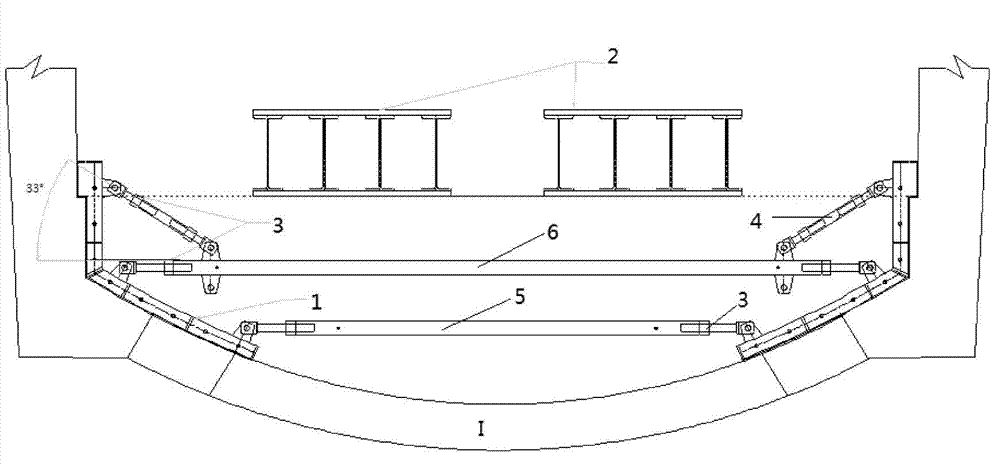

[0028] Such as Figure 1-6 As shown in the figure, a combined reinforcement device and height-increasing shoe system for the low side wall of the inverted arch, the system includes the formwork of the low side wall of the inverted arch 1, a simple steel trestle 2, the front and back buckle adjustment top wire 3, and the formwork of the low side wall to reinforce the top slope Strut 4, horizontally reinforced bottom support rod 5, horizontally reinforced top support rod 6, inverted arch low side wall reinforcement bracket 7, inverted arch trestle heightening boots 8, the pouring concrete of the inverted arch low side wall includes the concrete in the middle section of the bottom of the inverted arch I. Inverted arch low side wall concrete II, filled concrete III.

[0029] Wherein, the inverted arch low side wall formwork 1 is arranged at the inverted arch that has been excavated, and the inverted arch low side wall formwork 1 is provided with a horizontally arranged horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com