A falling film evaporation heat exchange device with flow phase change energy storage

A falling-film evaporation and heat exchange device technology, which is applied in the operation mode of machines, evaporators/condensers, machines using solar energy, etc. It is difficult to improve the efficiency and other problems, and achieves the effect of solving the large change rate of the phase change volume, solving the corrosiveness and high explosion limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

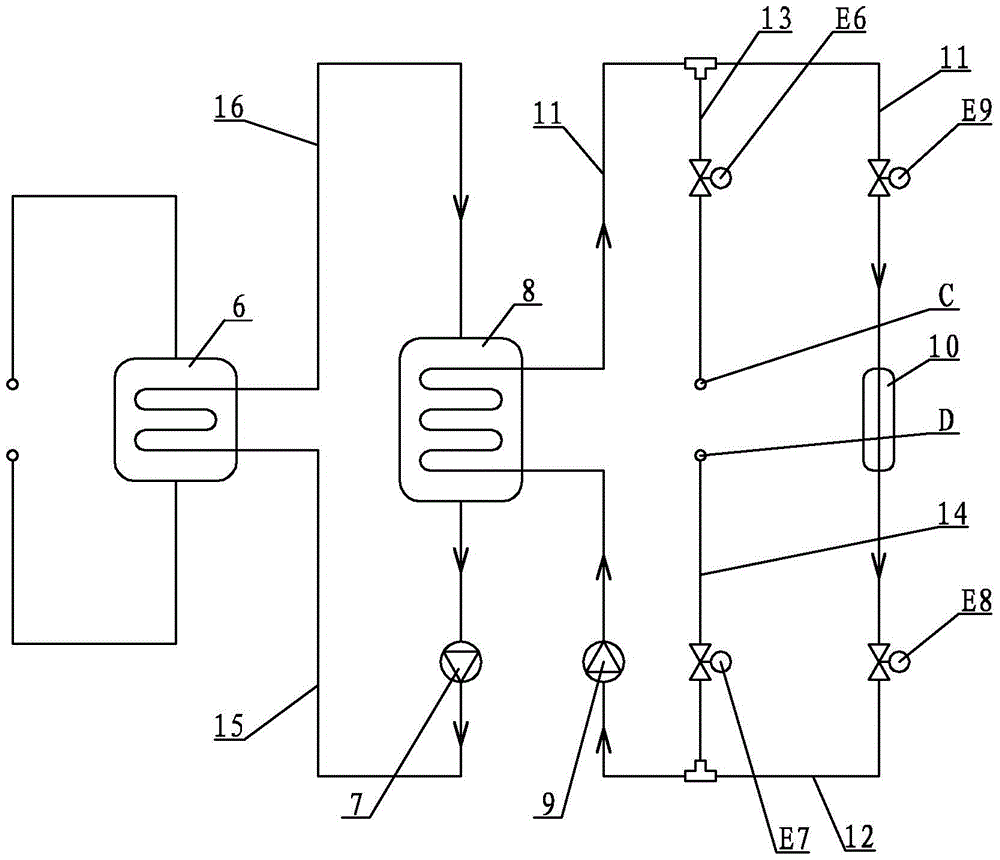

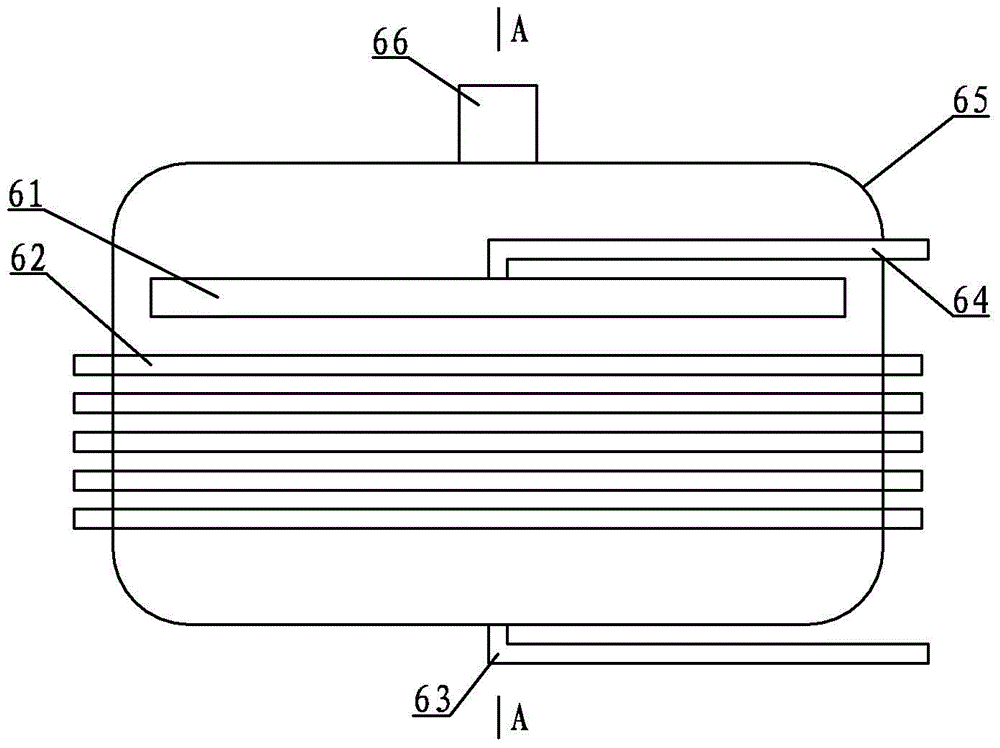

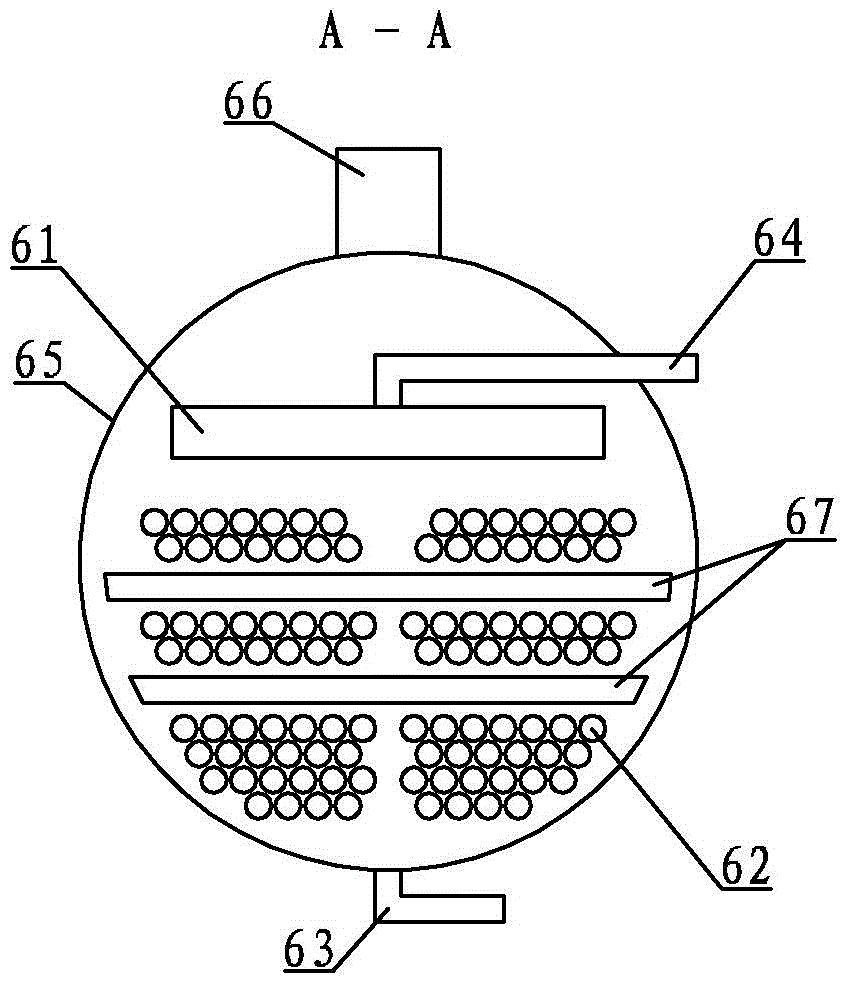

[0018] Specific embodiment one: combination Figure 1 ~ Figure 6 To illustrate this embodiment, this embodiment includes a falling film energy storage evaporator 6, a stainless steel magnetic pump 7, an energy storage tank 8, a water pump 9, a solar collector 10, a first solenoid valve E9, a second solenoid valve E8, and a second solenoid valve E8. Three solenoid valve E6, fourth solenoid valve E7, first pipe 11, second pipe 12, third pipe 13, fourth pipe 14, fifth pipe 15, and sixth pipe 16, falling film type The energy storage evaporator 6 is composed of a liquid distributor 61, an oil return pipe 63, a liquid supply pipe 64, an evaporator shell 65, two middle separators 67 and multiple sets of phase-change microemulsion outer surface strengthening tube bundles 62, and a liquid distributor 61 Horizontally arranged in the evaporator shell 65, one end of the liquid supply pipe 64 is connected with the liquid distributor 61, the other end of the liquid supply tube 64 leads to th...

specific Embodiment approach 2

[0019] Specific implementation manner two: combination Figure 5 To illustrate this embodiment, the phase transition temperature of the organic phase change microemulsion of this embodiment ranges from 4°C to 8°C. This temperature range enables the phase change energy storage material to have the dual functions of cold storage and heat supply, and the material is also liquid at room temperature and can be directly charged. The other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination Figure 5 To describe this embodiment, the phase transition temperature range of the organic phase change microemulsion of this embodiment is 6°C. This temperature makes the phase-change energy storage material have the dual functions of cold storage and heat supply, and the material is also liquid at room temperature and can be directly charged. Other components and connection relationships are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com