Spun-bonded nonwoven fabric drying device

A technology of spun-bonded nonwovens and drying equipment, which is applied in the direction of non-progressive dryers, drying solid materials, and drying solid materials without heating. It can solve the problems of broken filaments affecting the normal production, and prevent thermal oxidation. Degradation, drying effect with high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

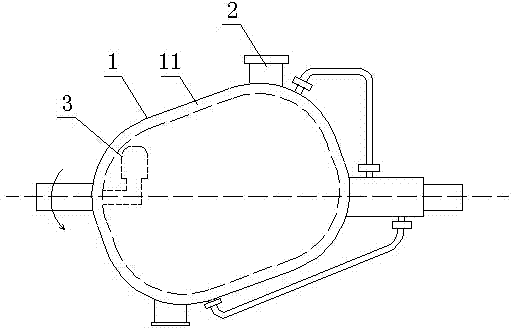

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0013] Such as figure 1 A spun-bonded nonwoven fabric drying device shown includes a tank body 1, on which a material inlet 2 is arranged; the tank body 1 has a jacket 11 structure, and heat transfer oil or steam is introduced into the jacket 11 , can rapidly heat the material added to the tank body 1.

[0014] The tank body 1 is provided with a vacuum pumping device 3, so that the whole tank body 1 is in a vacuum state, and the air and moisture in the drum can be removed in time, which can prevent thermal oxidation degradation of slices, and the drying quality is high.

[0015] The tank body 1 is arranged on an incline, and the material shakes left and right in the rotating tank body 1 to avoid overheating caused ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com