Rotary kiln multistage sealing structure

A sealing structure and rotary kiln technology, applied in the direction of rotary drum furnace, furnace, lighting and heating equipment, etc., can solve the problems of blocking, general sealing effect, leakage, etc., achieve good toughness, good sealing effect, and avoid excessive wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

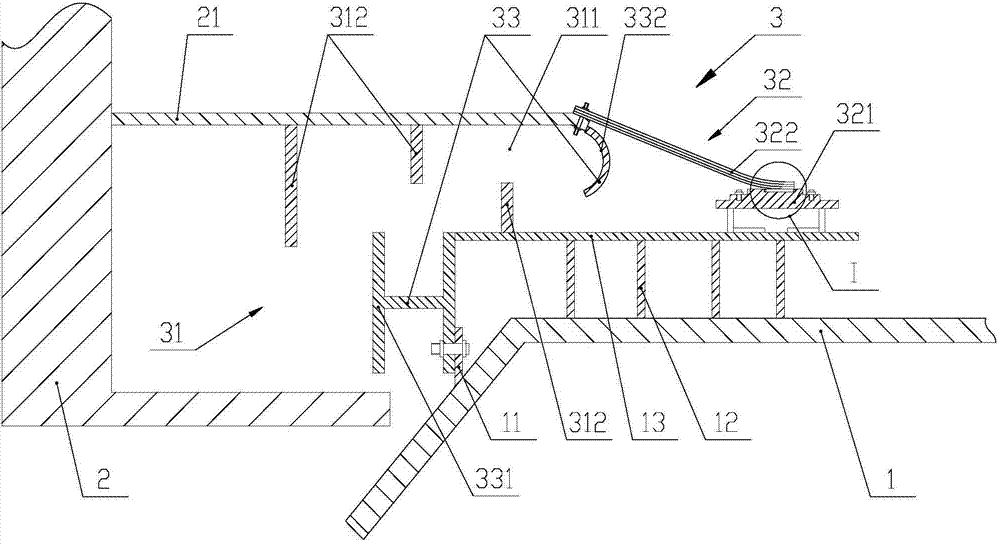

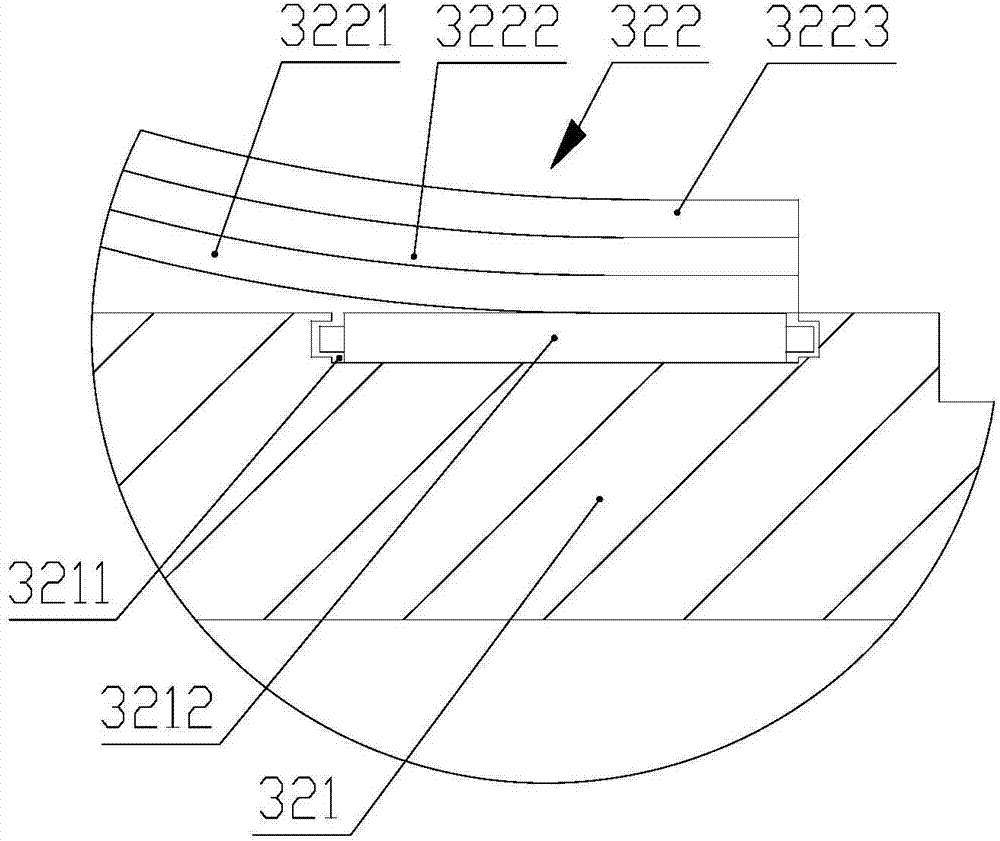

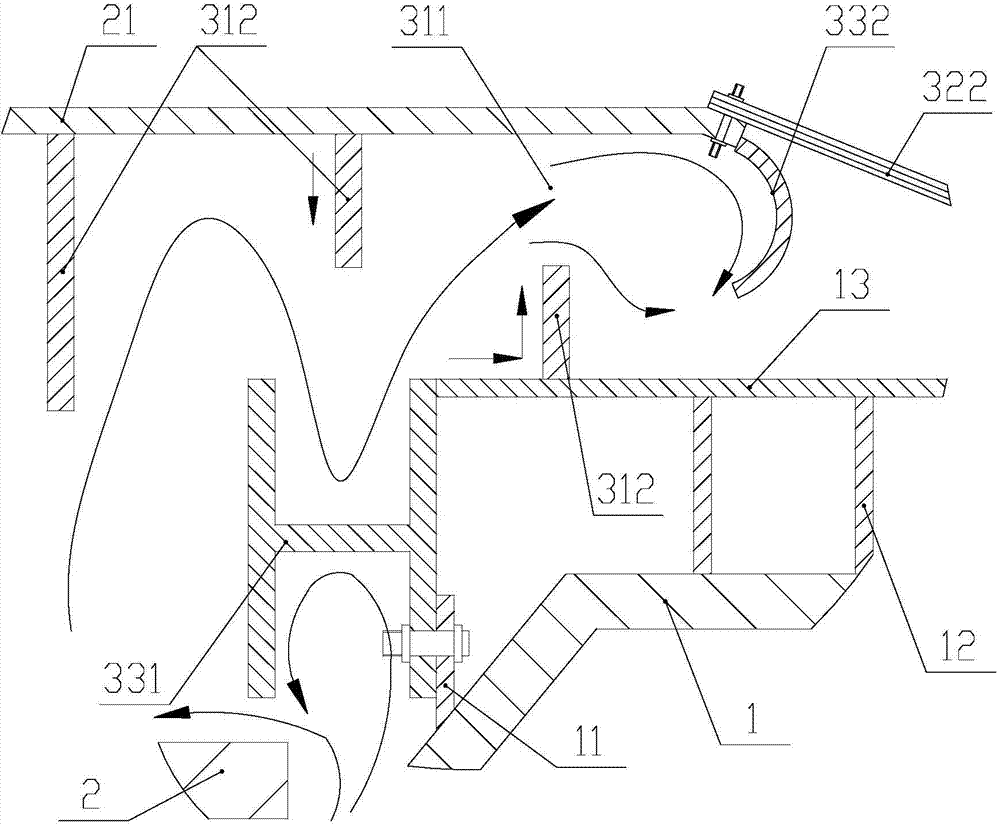

[0021] Such as figure 1 As shown, the multi-stage sealing structure of the rotary kiln includes a rotary kiln shell 1, a kiln head cover 2 and a sealing device 3; There is a gap between the kiln shell 1 and the kiln head cover 2; the sealing device 3 is arranged at the gap between the rotary kiln shell 1 and the kiln head cover 2, and the sealing device 3 includes a labyrinth structure 31 and is arranged on the labyrinth structure. 31 outside the fish scale structure 32; the sealing device 3 also includes a reflection structure 33; the opening of the labyrinth structure 31 near the fish scale structure 32 side is the labyrinth outlet 311; the labyrinth outlet 311 is also the internal air flow of the rotary kiln cylinder The outlet flowing out of the labyrinth structure 31; the reflection structure 33 includes a return scoop 331 arranged in the gap between the rotary kiln s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com