Gap measurement device for combustor, and gap measurement method

A technology of measuring device and measuring method, applied in combustion method, measuring device, gas turbine device, etc., can solve the problem that there is no size measuring device capable of measuring the annular gap between the cyclone support cylinder and the combustion cylinder, and the cyclone support cannot be measured. The annular gap between the cylinder and the combustion cylinder can be solved to achieve the effect of reliable shooting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Hereinafter, embodiments of the present invention will be described in detail based on the drawings. However, the scope of the present invention is not limited to the following embodiments. The dimensions, materials, shapes, relative arrangements, and the like of components described in the following embodiments are not intended to limit the scope of the present invention thereto, but are merely illustrative examples. In the following embodiments, a case where it is applied to a combustor constituting a gas turbine will be described.

[0067]

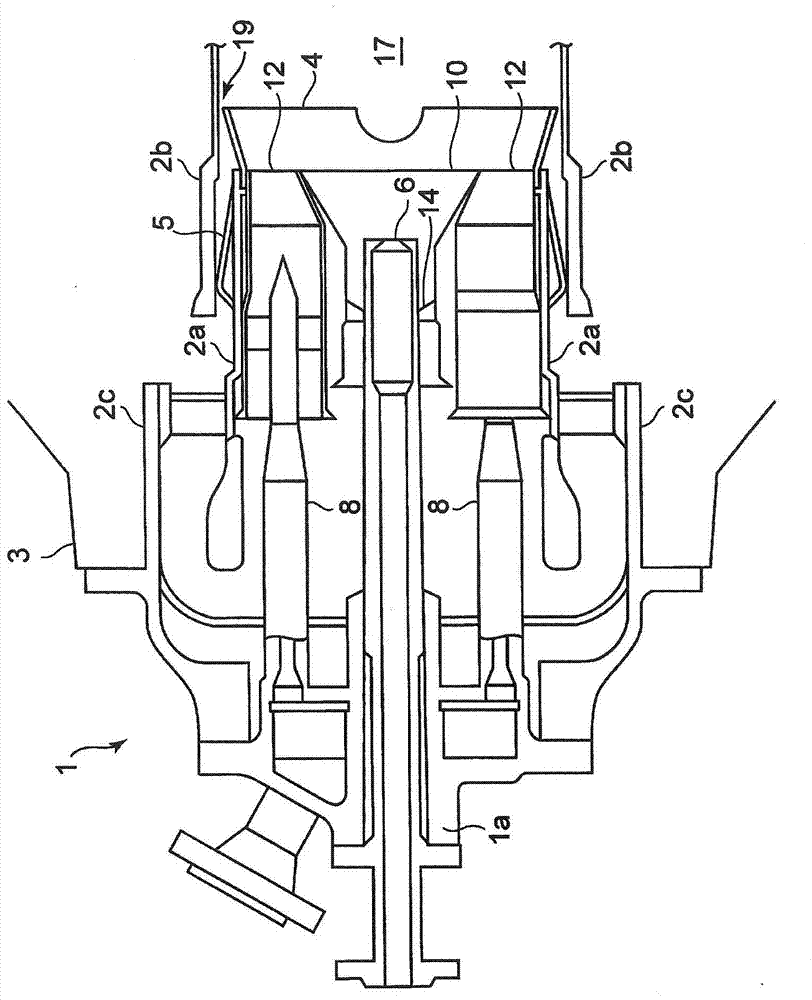

[0068] figure 1 It is a sectional view showing the structure of the combustor according to the embodiment of the present invention.

[0069] Such as figure 1 As shown, the combustor 1 is equipped with: a swirler support cylinder 2a (equivalent to the first cylinder, sometimes called an inner cylinder) provided on the fuel supply side; Combustion cylinder 2b (corresponding to the second cylinder body; sometimes referred to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com