Cutting apparatus

A technology of cutting device and camera, applied in fine working devices, parts of grinding machine tools, grinding/polishing equipment, etc., can solve problems such as difficulty in finding bevel cuts, inability to properly detect incision offset, etc., and achieve reliable shooting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

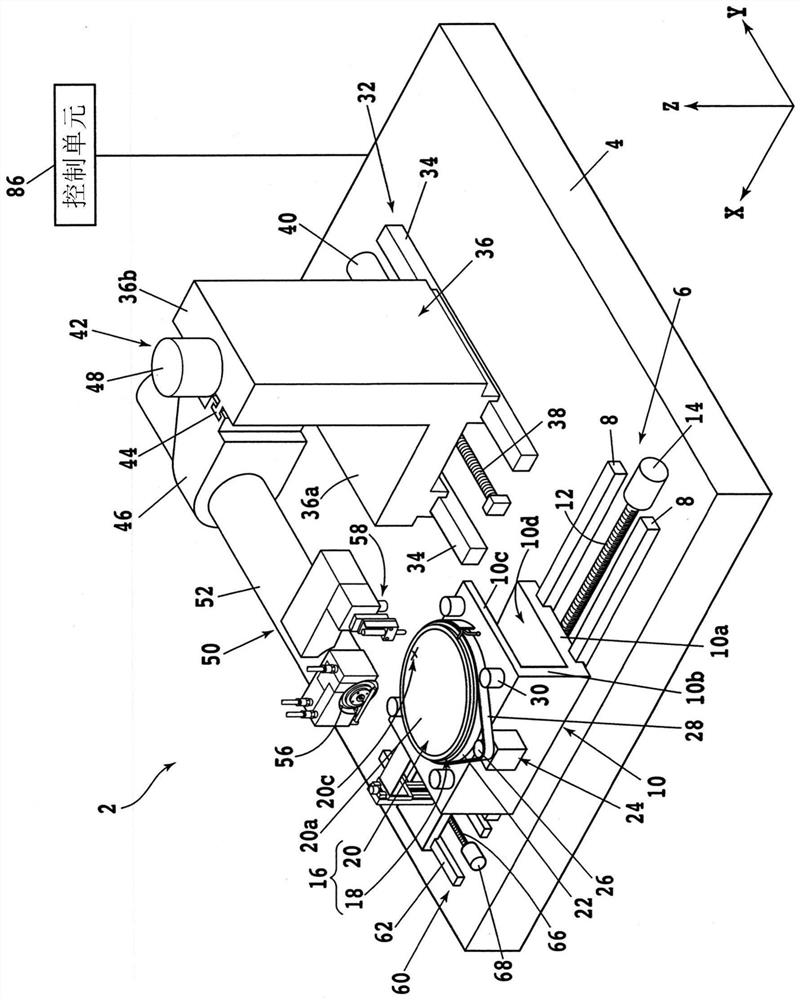

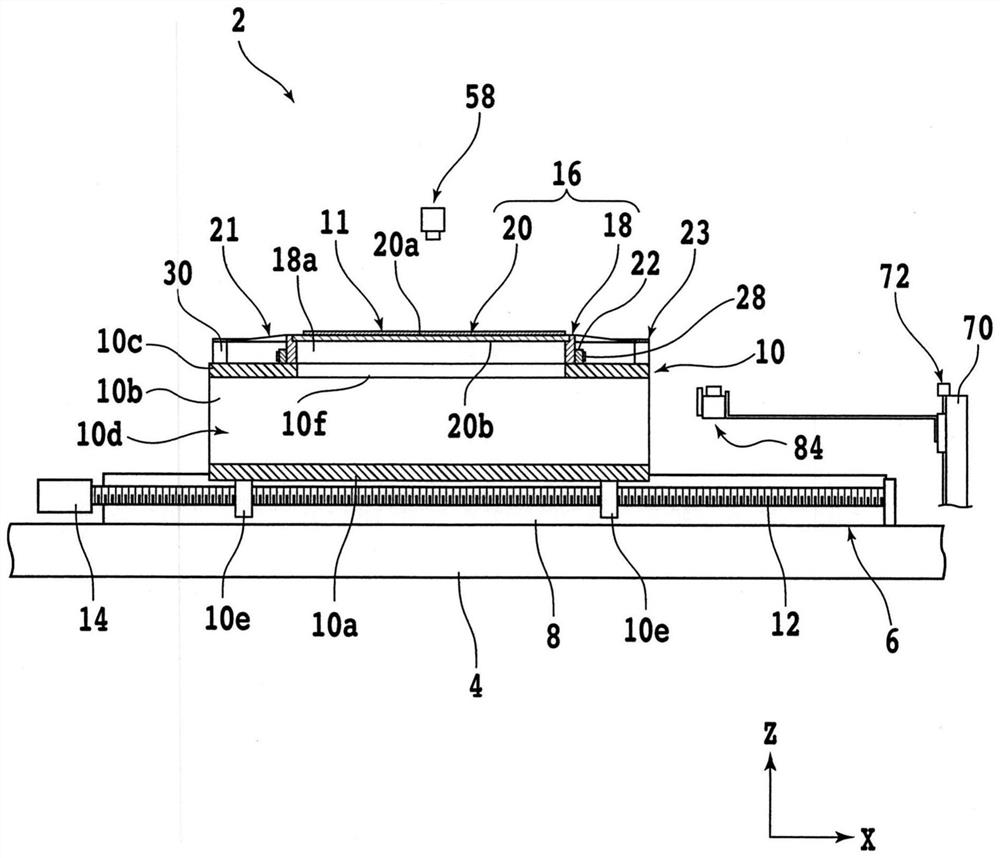

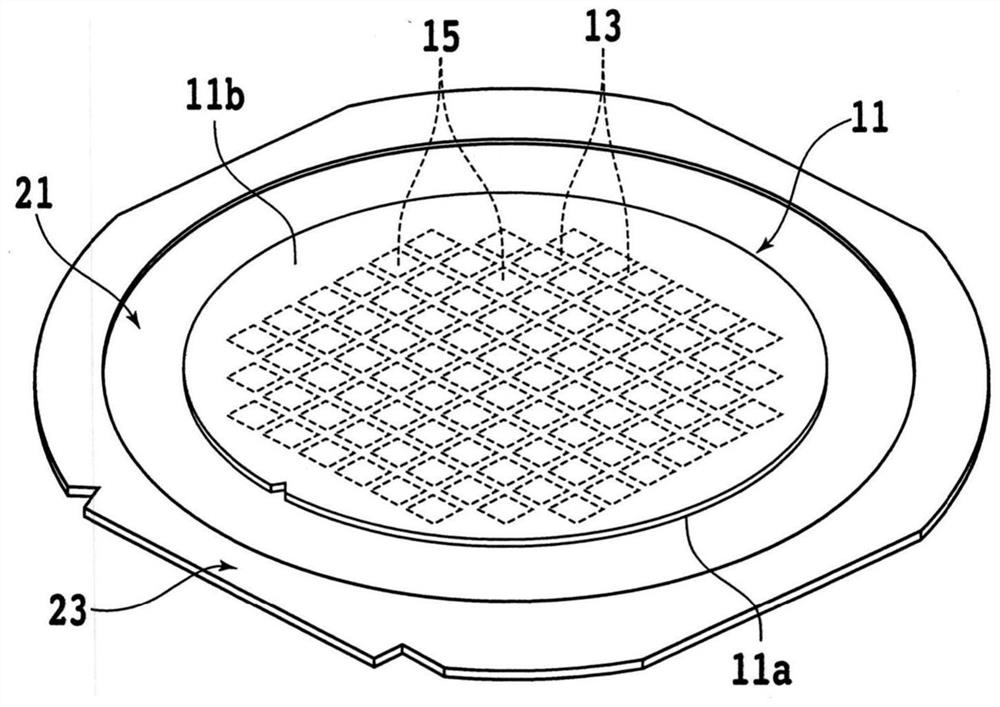

[0027] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a perspective view showing a configuration example of the cutting device 2 of the present embodiment. In addition, in figure 1 In , some components of the cutting device 2 are represented by functional blocks. In addition, the X-axis direction (machining feed direction), the Y-axis direction (index feed direction), and the Z-axis direction (vertical direction) used in the following description are perpendicular to each other.

[0028] like figure 1 As shown, the cutting device 2 has a base 4 that supports each component. A ball screw type X-axis moving mechanism (first feed mechanism, machining feed mechanism) 6 is arranged on the upper surface of the base 4 . The X-axis moving mechanism 6 includes, for example, a pair of X-axis guide rails 8 fixed to the upper surface of the base 4 and substantially parallel to the X-axis direction. The X-axis moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com