Structure for masks

A light shield and through-hole technology, applied in the field of light shield structure, can solve the problem of high output voltage of sensor circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

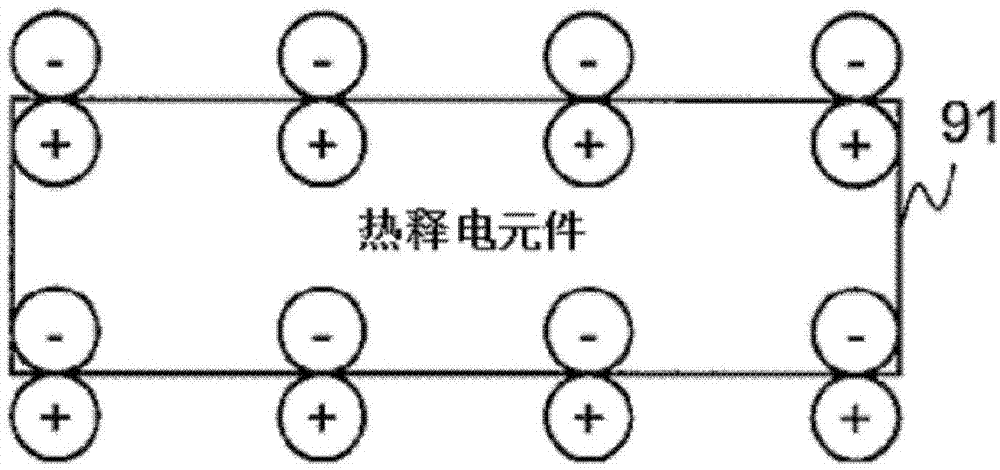

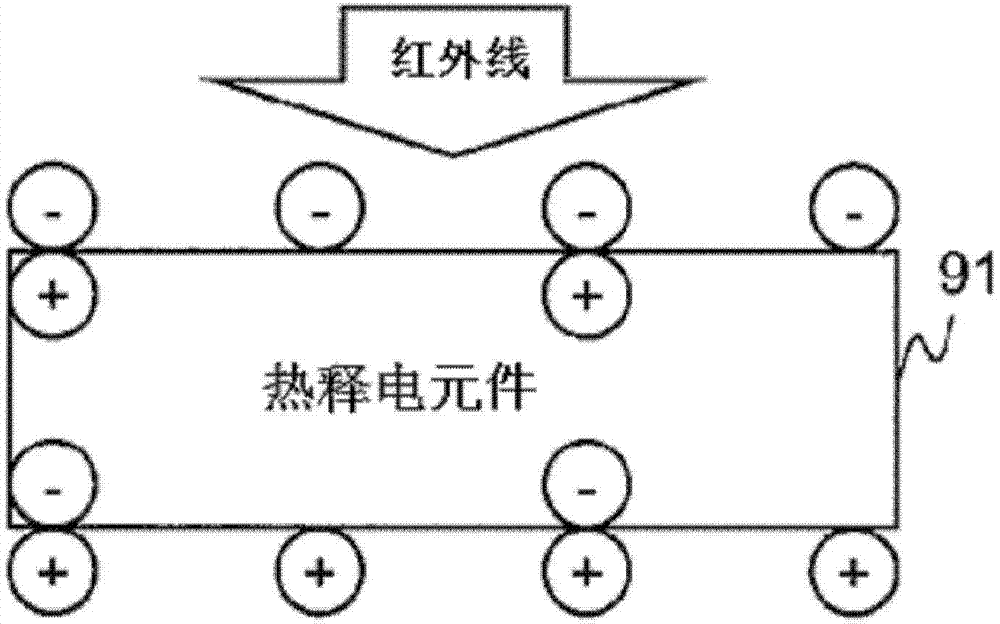

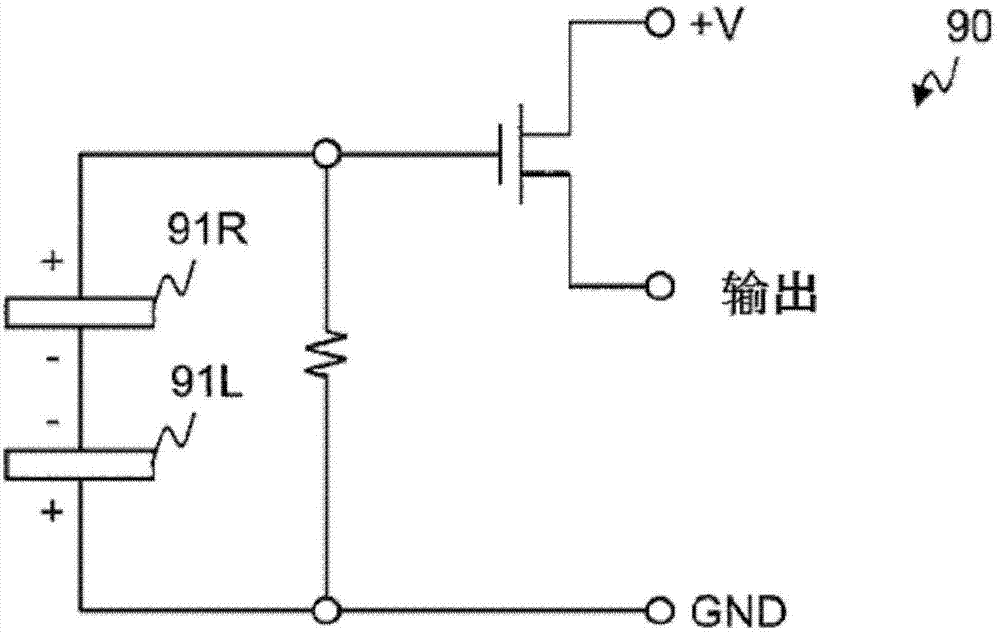

[0043] The pyroelectric sensor having the structure including the light shield 110 according to the first embodiment will be described.

[0044] Figure 8 A shows the external view of the hood 110, Figure 8 B shows an example of the dimensions of the opening pattern 112 of the shade 110 .

[0045] The shade 110 includes: a sheet portion 111 for blocking infrared rays; an opening pattern 112 formed of a plurality of through holes formed in the sheet portion 111 ; and a mounting portion 113 . The light shield structure includes a sheet portion 111 and an opening pattern 112 .

[0046] For example, the shade 110 (perforated metal plate) is molded by pressing a metal plate.

[0047] On the detection surface of the pyroelectric sensor, the arrangement direction of the two pyroelectric elements of the pyroelectric sensor is defined as the x direction, and the direction perpendicular to the x direction on the detection surface is defined as the y direction. The opening pattern 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com