Method for embedding at least one component into a printed circuit board

A technology for printed circuit boards and components, applied in the field of embedding at least one component in printed circuit boards, capable of solving problems such as device errors, adverse effects of contact connections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

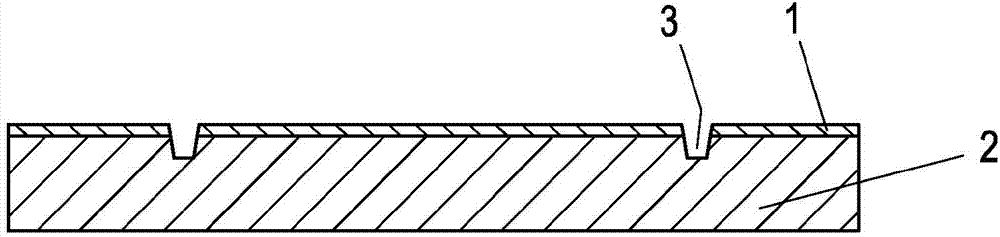

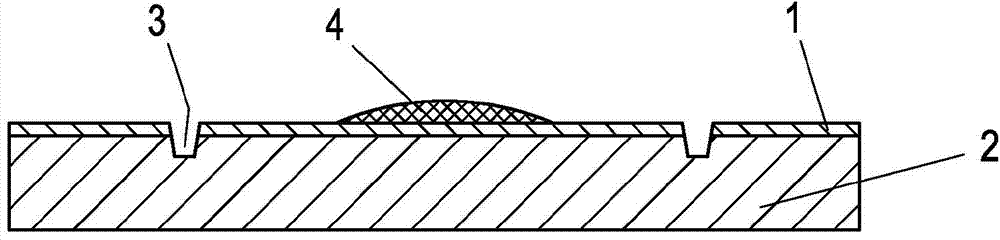

[0036] refer to Figures 1 to 10 , the method according to the invention for producing a printed circuit board comprising at least one embedded component, or such a printed circuit board according to the invention will be described as follows.

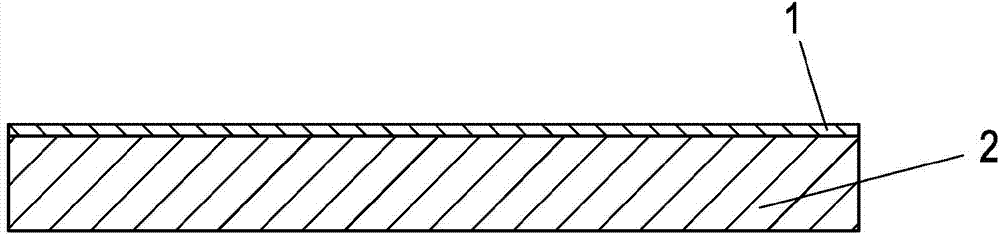

[0037] figure 1 The first step of the method is shown, specifically providing an underlying conductive thin foil 1, for example 2 micron copper foil, which is supported by a thicker underlying support layer 2, for example 70 micron copper foil, wherein layer 1 and 2 are connected to each other. The underlying conductive foil / support layer combination can also be provided with an insulating coating (not shown here), such as a resin layer, which is applied on the upper side, that is to say on the conductive foil 1, which is for example 5 to 15 microns thick . Due to such a coating, the relatively rough surface of the conductive foil (which usually consists of copper) is covered, which has proven to be expedient when fixing components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com