Hydrostatic extrusion hollow profile device with movable core support for die core

A hollow profile and hydrostatic extrusion technology, which is applied in the field of hydrostatic extrusion hollow profile devices, can solve the problems of uneven wall thickness, transverse fracture and longitudinal fracture of the mold core, etc., so as to avoid uneven wall thickness and improve the force state, the effect of increasing stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

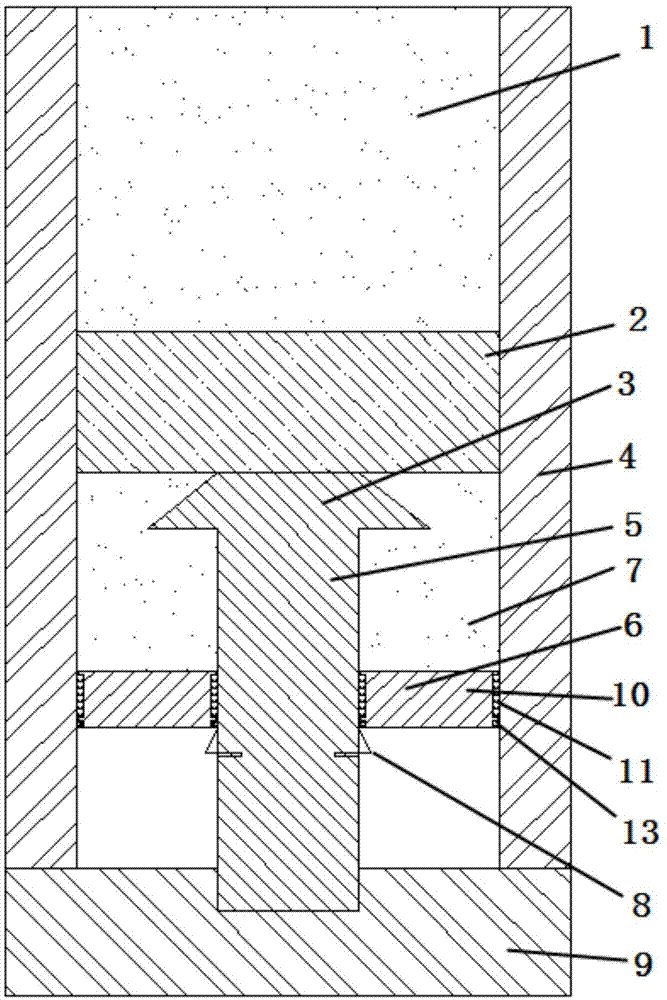

[0044] 10 steel round pipes were produced by hydrostatic extrusion, the outer diameter of the finished product was 200 mm, and the inner diameter was 100 mm.

[0045] The inner diameter of the extrusion cylinder 4 is 200mm.

[0046] Blank 2 size: outer diameter 200mm, height 400mm.

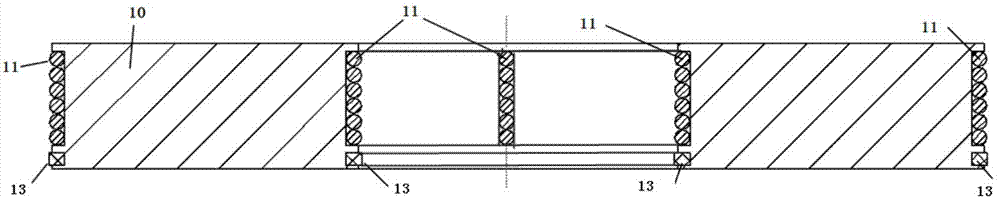

[0047] The outer diameter of the second groove of the movable ring 10 is 110mm, the width is 10mm, and the depth is 4mm. The outer diameter of the fourth groove is 200mm, the width is 20mm, and the depth is 8mm.

[0048] The sealing ring 13 is divided into the first sealing ring 13-1 and the second sealing ring 13-2, both of which are O-shaped sealing rings. In the groove, its top protrudes from the second groove. The second sealing ring 13-2 has an outer diameter of 200mm, an inner diameter of 180mm, and a height of 20mm, and is stuck in the fourth groove, and its top protrudes from the fourth groove to realize sealing.

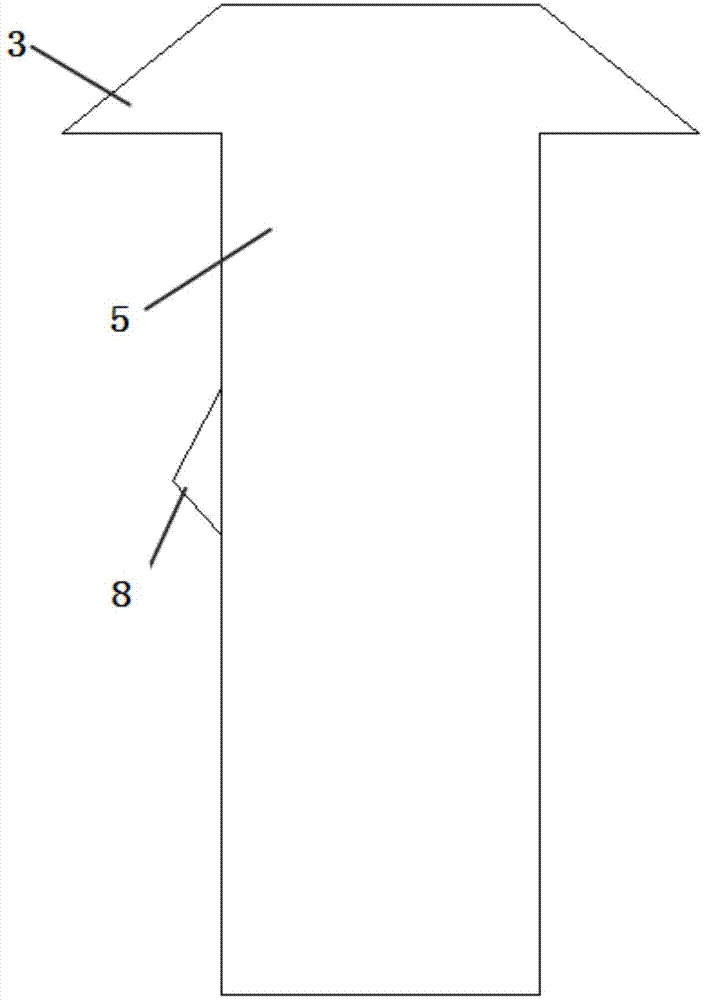

[0049]Mold core 5: the mold core 5 includes a cylinder and a truncated c...

Embodiment 2

[0061] The 7075 aluminum alloy square pipe was prepared by hydrostatic extrusion, the cross section of the pipe was rectangular, the outer dimension was 300mm×200mm, and the wall thickness was 10mm.

[0062] The cross-section of the extrusion cylinder 4 is rectangular, and the cross-sectional size of the inner wall is 300mm×200mm.

[0063] The blank 2 is a cuboid with a size of 300mm×200mm×100mm. At the center, a square cone whose base size is 30mm×20mm and whose height is 15mm is processed.

[0064] The sealing ring 13 is divided into three types, all of which are rectangular sealing rings with a cross-sectional size of 10mm×10mm, wherein the outer diameter of the first sealing ring 13-1 is 302mm×206×10mm, and the outer diameter of the second sealing ring 13-2 is It is 304mm×208×10mm, and the inner diameter of the third sealing ring 13-3 is 300mm×200mm×10mm.

[0065] Mold core 5: The mold core 5 includes two cuboids and a square cone. Wherein the size of the first cuboid i...

Embodiment 3

[0074] The hydrostatically extruded AZ80 magnesium alloy special-shaped pipe with an equilateral pentagonal cross section, the inner equilateral pentagonal circumscribed on a circle with a radius of 50mm, and a wall thickness of 20mm.

[0075] The inner wall of the extrusion cylinder 4 is an equilateral pentagon, circumscribed on a circle with a radius of 50mm.

[0076] The blank 2 is an equilateral pentagonal column, the outer pentagon is inscribed in a circle with a radius of 50mm, and the height is 70mm.

[0077] The sealing ring 13 includes a first sealing ring 13-1 and a second sealing ring 13-2, both of which are O-shaped sealing rings, with a cross-sectional size of 20mm×10mm. Wherein the outer diameter of the second sealing ring 13-2 is 50 mm, and the outer diameter of the first sealing ring 13-1 is 36 mm.

[0078] Mold core 5: Mold core 5 includes two equilateral pentagonal columns and a pyramidal body whose base is equilateral pentagonal, wherein the equilateral pen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com