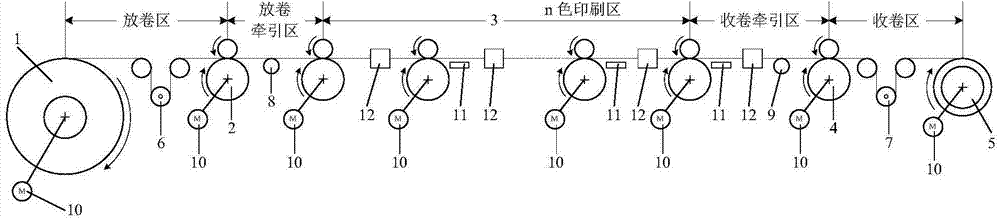

Method for automatically acquiring initial reeling and unreeling radius of reel material printing equipment

A technology of printing equipment and automatic acquisition, which is applied to general parts of printing machinery, printing, printing machines, etc., can solve problems such as errors and low efficiency, achieve obvious errors, low efficiency, and improve equipment automation and production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

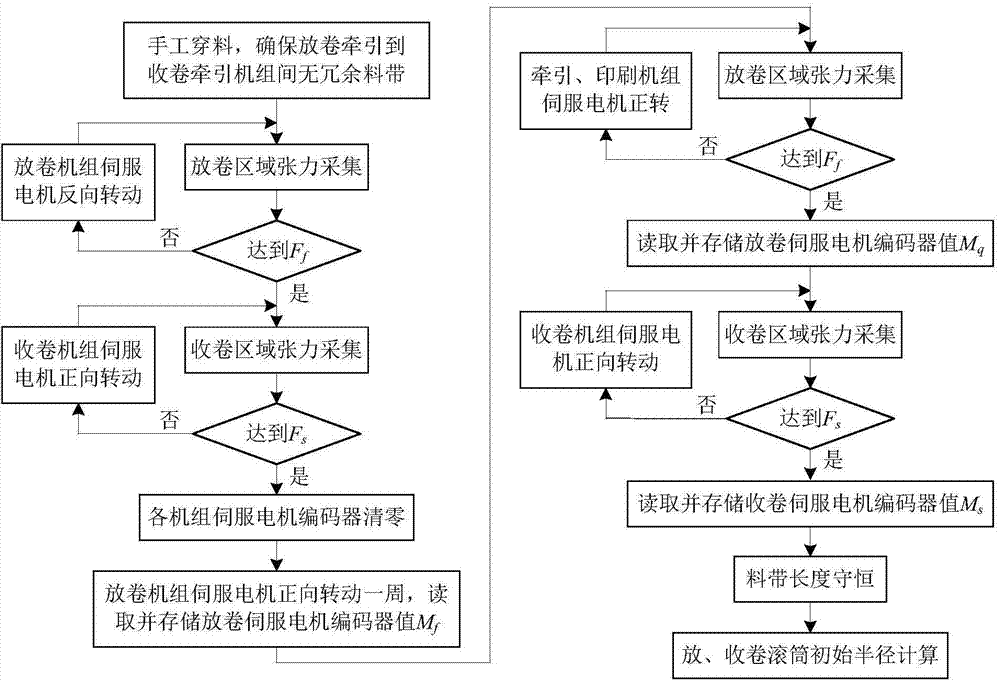

Method used

Image

Examples

Embodiment

[0070] Assume that the servo motor encoders of all units are 17-bit encoders, that is, the number of pulses output by the encoder for one rotation of the servo motor is 2 17 = 131072 pulses, so B s =B q =B f =131072; Radius R of driving roller of unwinding traction unit 2 q = 100mm.

[0071] After going through the above steps (1) to (7), the read encoder value M of the servo motor of unwinding traction unit 2 q and the encoder value M of the servo motor of the winding unit 5 s are 1022261 and 801465 respectively, then according to formula (4):

[0072] The initial radius of the unwinding drum is:

[0073] R f = R q M q B q = 100 × 1022261 131072 ≈ 779.92 ( mm ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com