Counteractive rod assembly of heavy industrial and mining vehicle

A reaction rod and assembly technology, which is applied to vehicle components, interconnection systems, suspensions, etc., can solve problems such as the easy collapse of the circlip and the easy failure of the connecting bolt of the reaction rod, so as to improve the force of the bolt and avoid easy failure , The effect of eliminating the defects of the collapsed circlip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

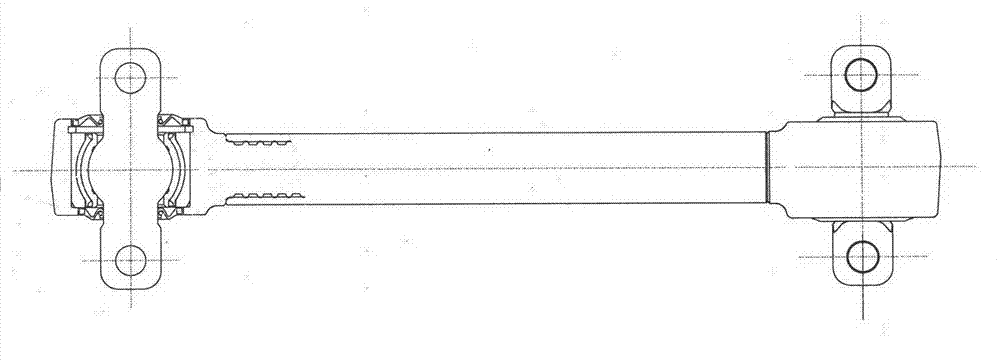

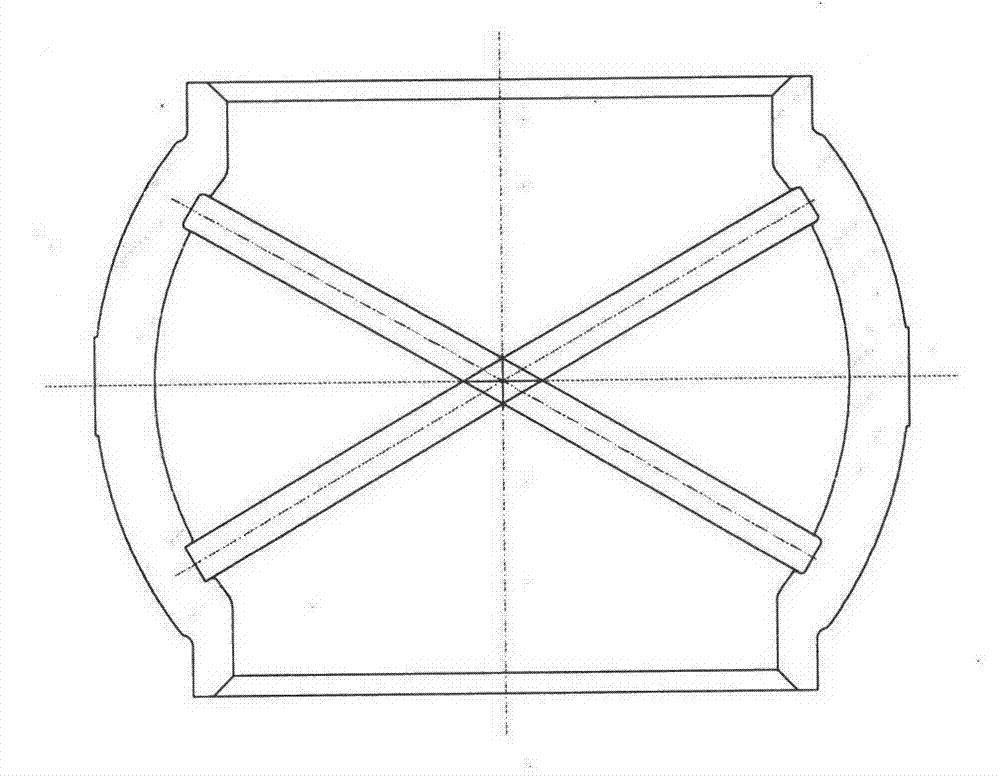

[0017] attached Figure 1-4 Among them, the two shells 2 are connected with the connecting rod 6, and fixed and shaped by hot pressing to form the metal skeleton of the reaction rod. The assembly method of the spherical pin assembly 5 is basically the same as that of the traditional rubber or polyurethane spherical pin assembly. After putting in place, assemble the circlip 3 or the plug, then apply grease in the cavity on both sides of the housing 2, and then assemble the small dustproof sealing ring 1 and the large dustproof sealing ring 4.

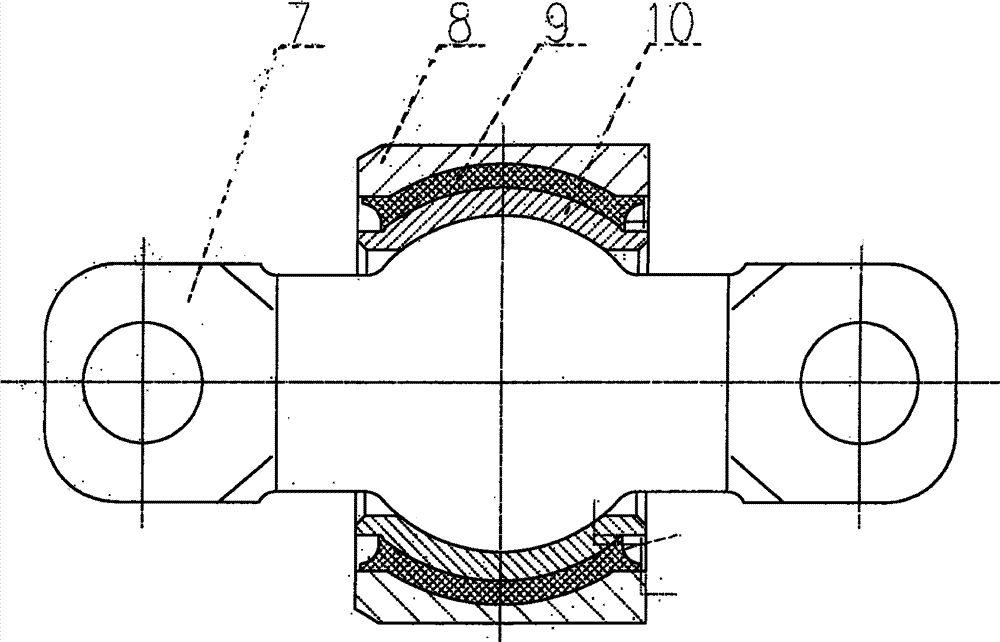

[0018] The spherical pin assembly 5 has a four-layer structure from the inside to the outside. The middle part of the spherical pin 7 is spherical, and the outer ring 10 of the friction pair is arranged outside the spherical surface of the middle part of the spherical pin 7. The mating surface between the two is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com