High-thermal-conductivity environment-friendly type epoxy resin composition and preparation method thereof

A technology of epoxy resin and composition, applied in the field of epoxy resin composition and preparation thereof, can solve the problems of air holes on the surface of plastic encapsulation materials, poor molding process performance, etc., and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

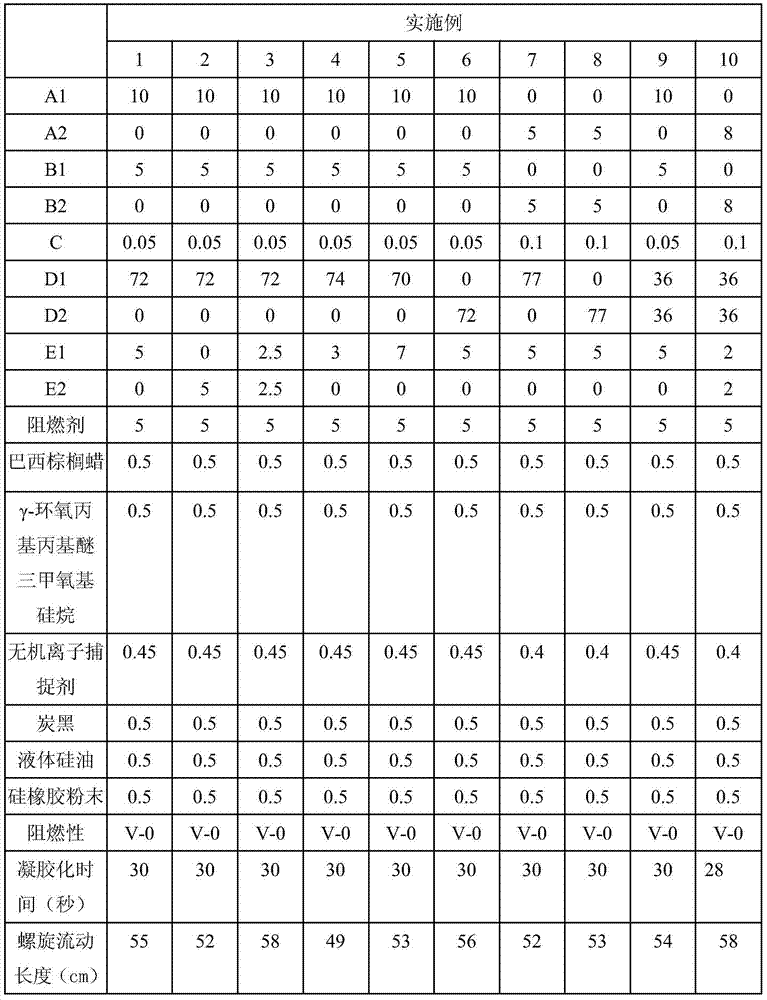

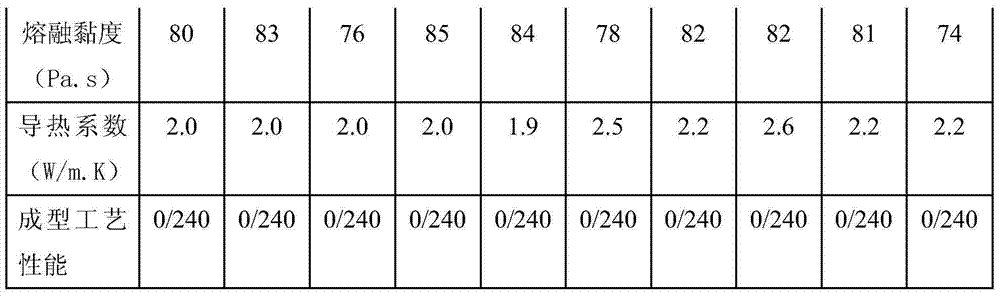

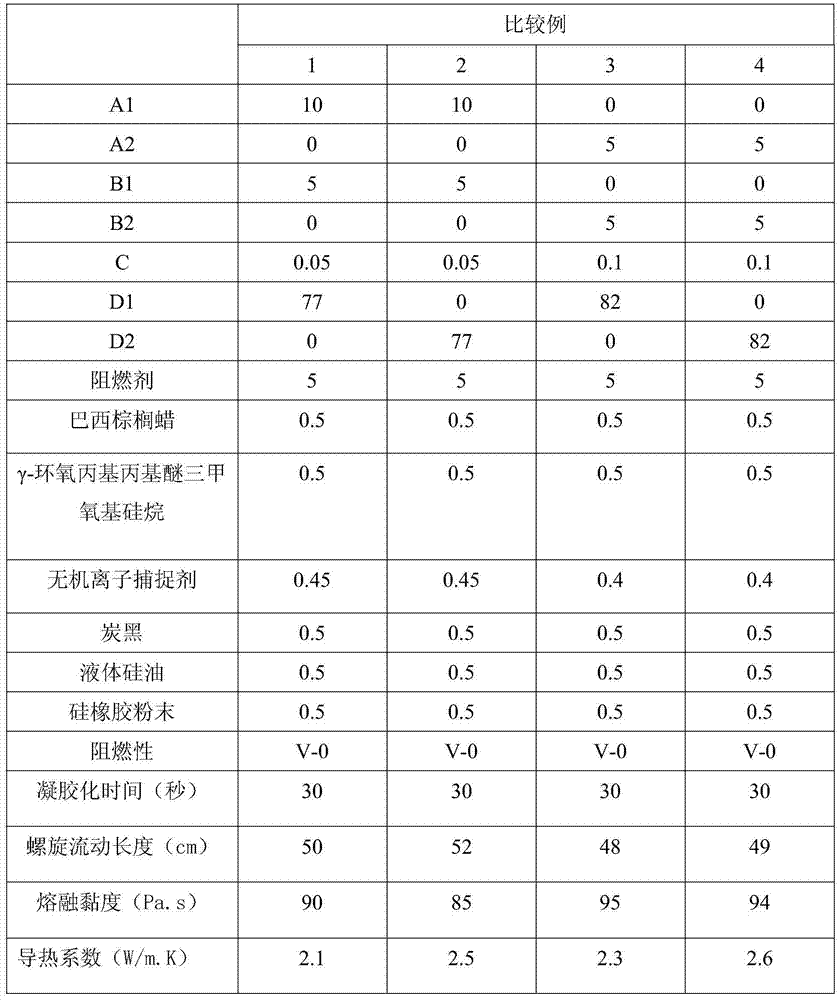

Examples

Embodiment 1

[0033] O-cresol novolac epoxy resin A ("N-665" manufactured by DIC Corporation of Japan) 15wt%

[0034] Phenol novolac resin B ("TD-2131" manufactured by DIC Corporation of Japan) 7wt%

[0035] Curing accelerator 2-methylimidazole C 0.5wt%

[0036] Crystalline silica powder D1 (d50 is 25μm) 72wt%

[0037] Ultrafine spherical silica powder E1 ("SC2500SQ" manufactured by Japan's Admatech Corporation, D50 is 0.5 micron) 5%wt%

[0038] Flame retardant 5wt%

[0039] Carnauba Wax 0.4wt%

[0040] γ-glycidyl propyl ether trimethoxysilane 0.5wt%

[0041] Inorganic ion scavenger 0.2wt% (IXE500 (Bi2O3·3H2O) manufactured by TOAGOSEI Co., Ltd, Japan)

[0042] Carbon black 0.5wt%

[0043] Liquid silicone oil 0.3wt%

[0044] Silicone rubber powder 0.5wt% (d50 is 1μm)

[0045] After weighing and mixing uniformly according to the above ratio, melt and knead evenly on a double-roller mixer preheated at a temperature of 70-100°C, remove the uniformly mixed material from the double-roller...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap