Construction machine

A technology for construction machinery and body, applied in construction, cranes, earthmoving machines/shovels, etc., can solve problems such as high manufacturing costs, fatigue, boom tipping, etc., to suppress the tipping of construction machinery, reduce fatigue, Operational safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

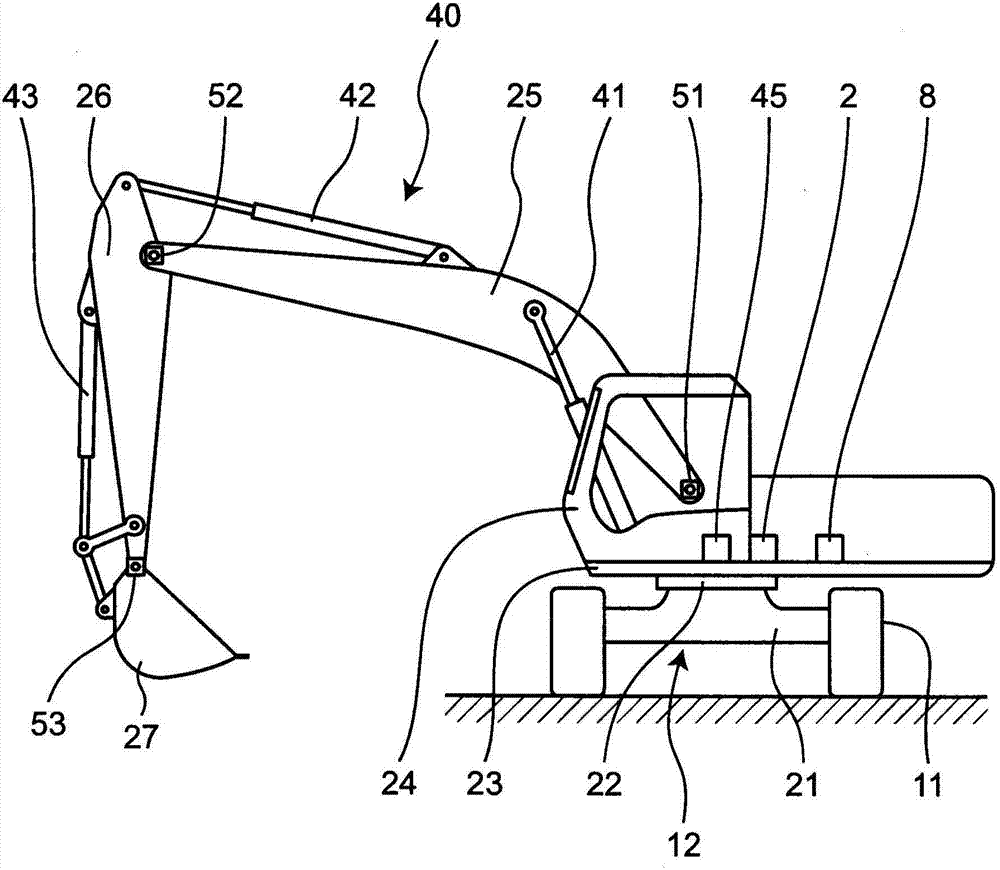

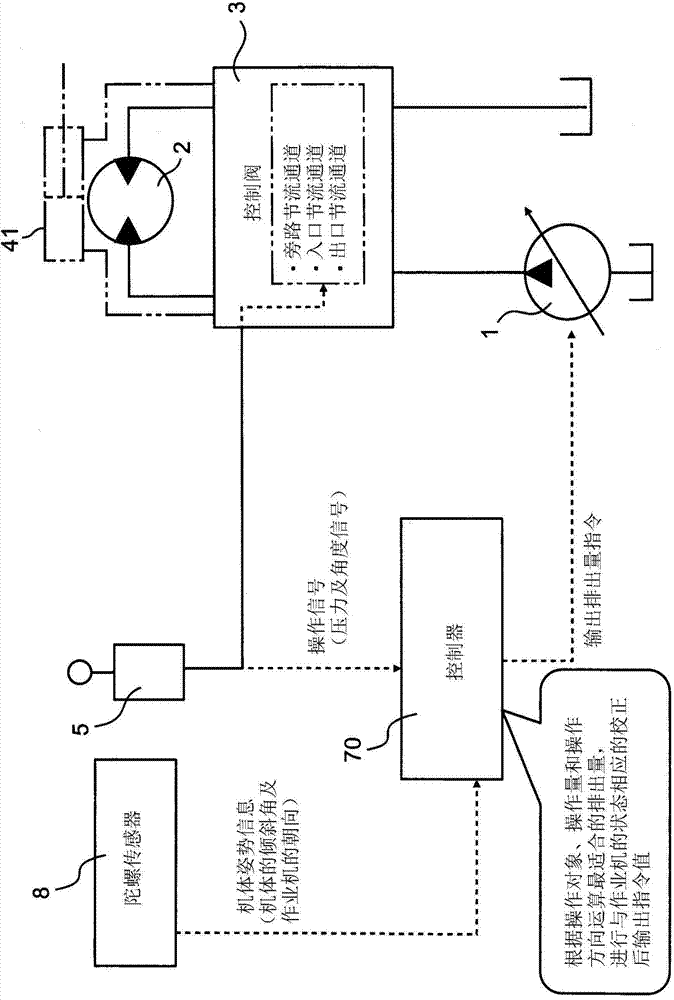

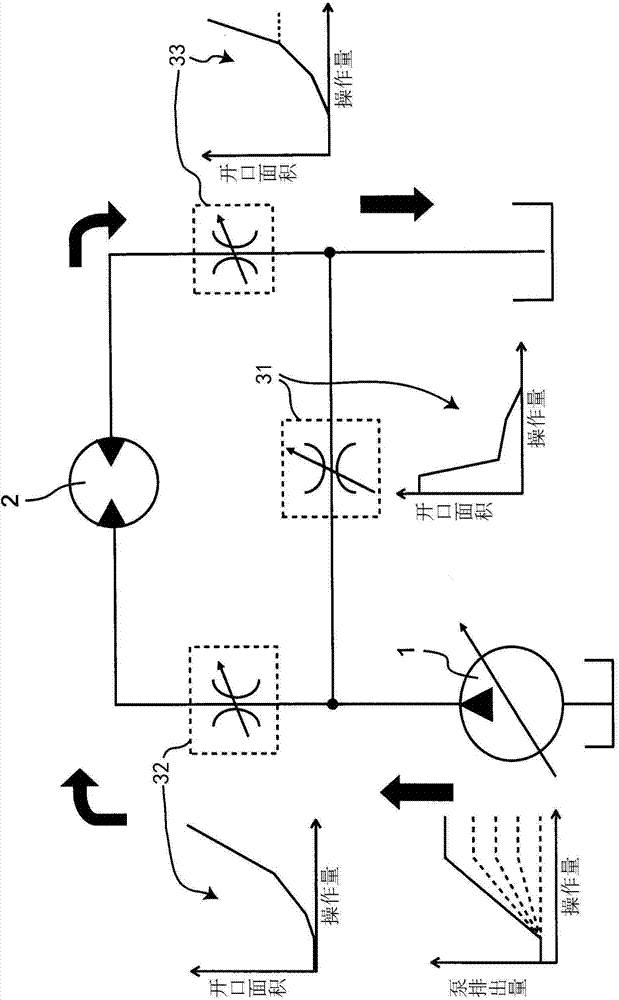

[0082] like figure 1 As shown, a hydraulic excavator as an example of the construction machine of the first embodiment includes a traveling device 11 and a body 12 provided on the traveling device 11 , and the body 12 has a lower portion 21 supported by the traveling device 11 ; An upper turntable 23 is provided on the lower part 21 so as to be able to turn by means of a turn mechanism 22 . A cab 24 is provided on one side in front of the turntable 23 , and a boom 25 is provided at the front center of the turntable 23 so as to be able to pitch. An arm 26 is provided at the front end of the boom 25 so as to be rotatable up and down, and a bucket 27 is provided at the front end of the arm 26 so as to be rotatable.

[0083] The boom 25 is pitched by the boom hydraulic cylinder 41 , the arm 26 is rotated by the arm hydraulic cylinder 42 , and the bucket 27 is rotated by the bucket hydraulic cylinder 43 . The hydraulic cylinders 41, 42, 43 described above are examples of actuator...

no. 2 approach

[0105] A hydraulic excavator as an example of the construction machine of the second embodiment, according to figure 1 The output of the boom rotation angle sensor 51 is shown to Figure 5 The illustrated pattern of the discharge amount of the hydraulic pump 1 at the time of correction is different from the hydraulic excavator of the first embodiment only in that the pattern is further corrected.

[0106] Therefore, since the hardware of the second embodiment is the same as that of the first embodiment, citing Figure 1~3 , Figure 5 And its description, only the different structures will be described below.

[0107] The second embodiment of Figure 8 The flow chart shown is the same as that of the first embodiment Figure 4 The flow chart shown is only the same as that in which step S6 has been added. Figure 4 Because they are different, steps S1 to S5 are omitted by citing the description of the first embodiment, and only step S6 will be described below.

[0108] The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com