A Coal Mine Underground Detection Robot

A robot and robot body technology, which is applied in mining equipment, safety devices, earth-moving drilling, etc., can solve the problems of low safety, low efficiency, and poor winding tightness, and achieves strong practicability, good tightness, rolling Lines for quick and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

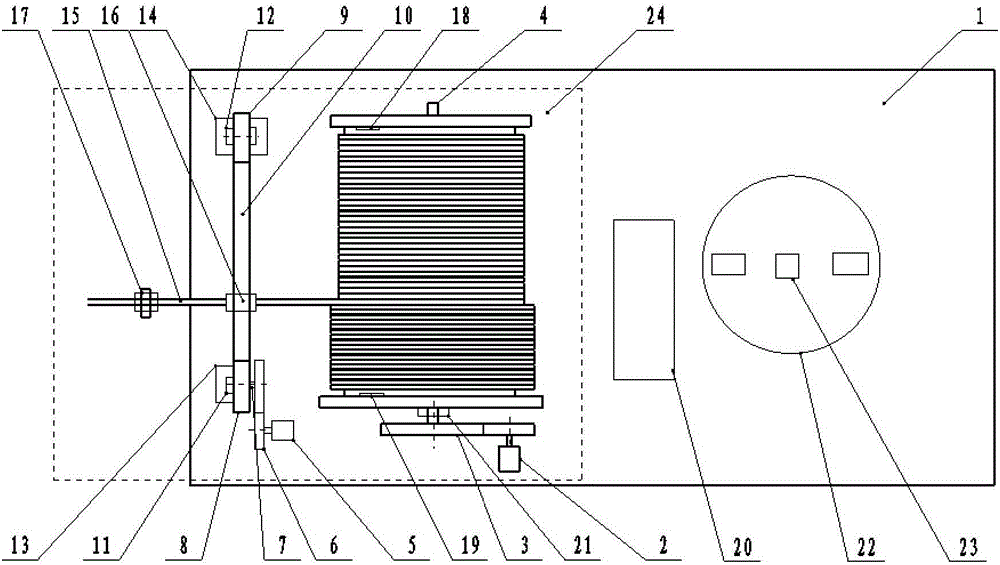

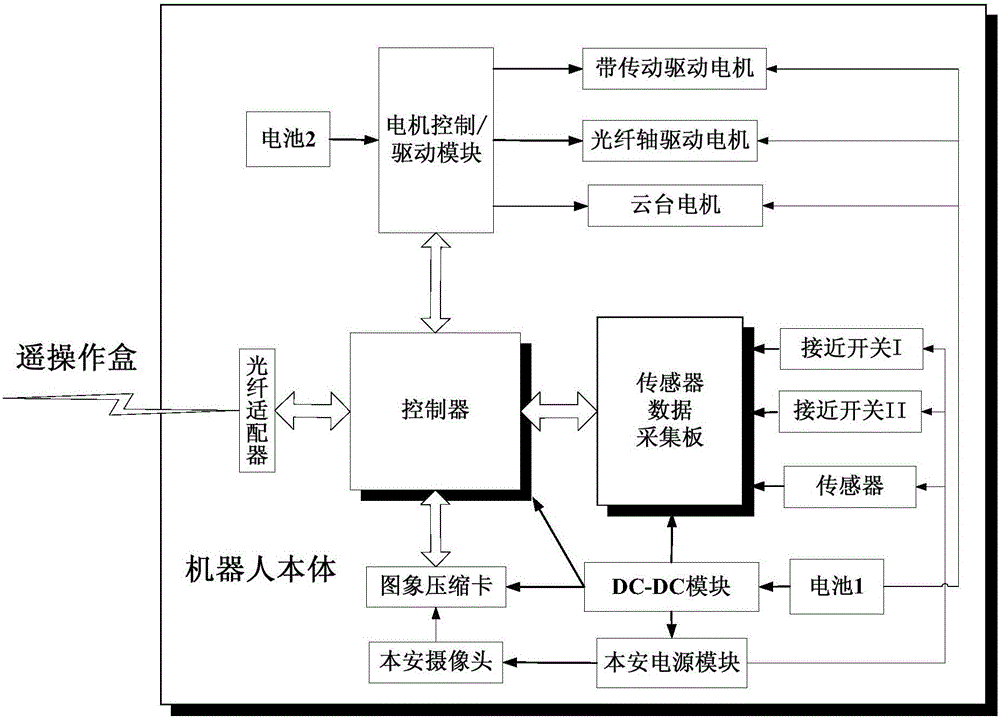

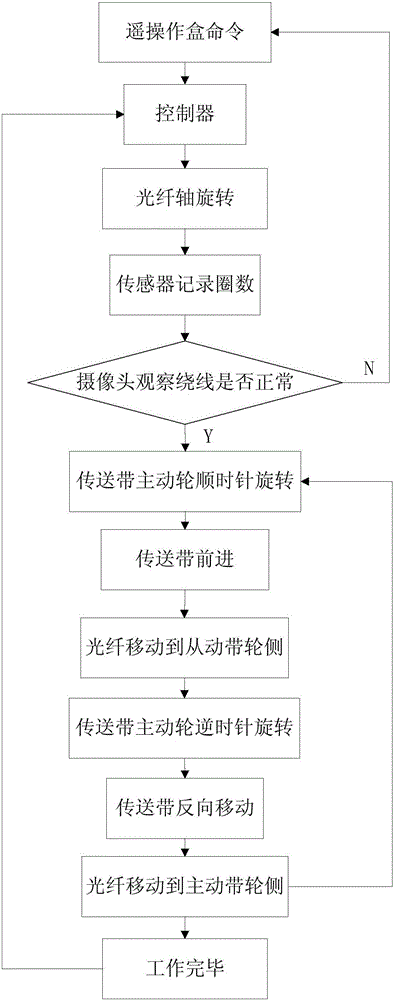

[0017] Such as figure 1 As shown, the automatic retractable optical fiber device 24 of the coal mine underground detection robot of the present invention is composed of the following structure: a robot body 1, which is filled with inert gas, adopts static positive pressure explosion-proof technology, and meets the requirements of the explosive gas environment in coal mines; an optical fiber shaft drives The motor 2 is arranged in the positive pressure cavity of the robot body 1 and is powered by the battery in the robot body; the first reduction device 3 is connected to the drive motor 2 at the input end and connected to the optical fiber shaft 4 with a dynamic seal at the output end. The design of the first reduction device 3 The flameproof enclosure is arranged in the positive pressure cavity of the robot body 1; an optical fiber shaft 4 is fixedly connected to the robot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com