Hydraulic oil cooler

A cooler and hydraulic oil technology, applied in the direction of transformer/inductor cooling, fluid pressure actuation device, fluid pressure actuation system components, etc., can solve the problems that power transformers affect the normal operation of power transformers, and achieve compact structure and low noise Low, good cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

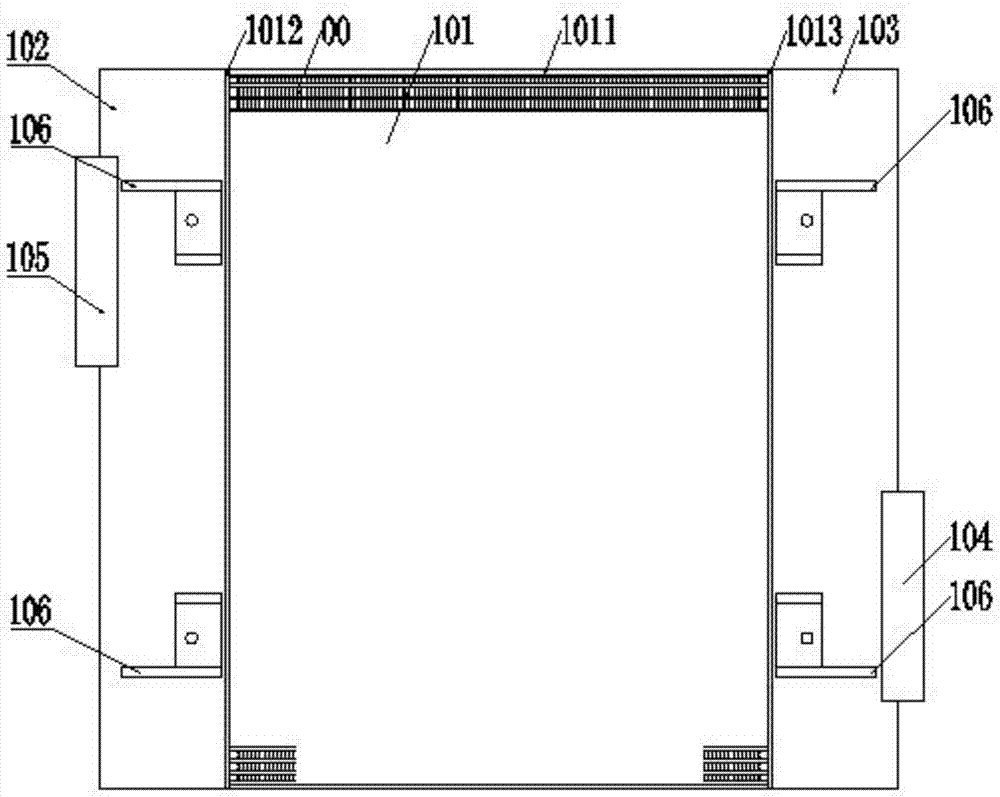

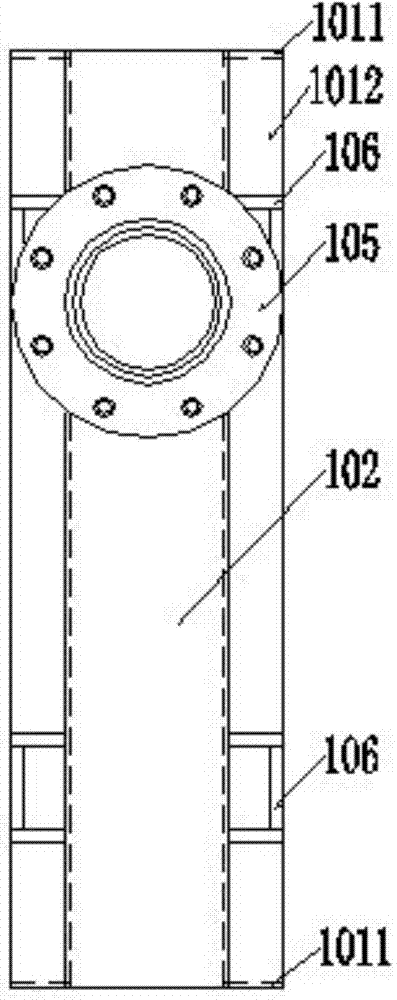

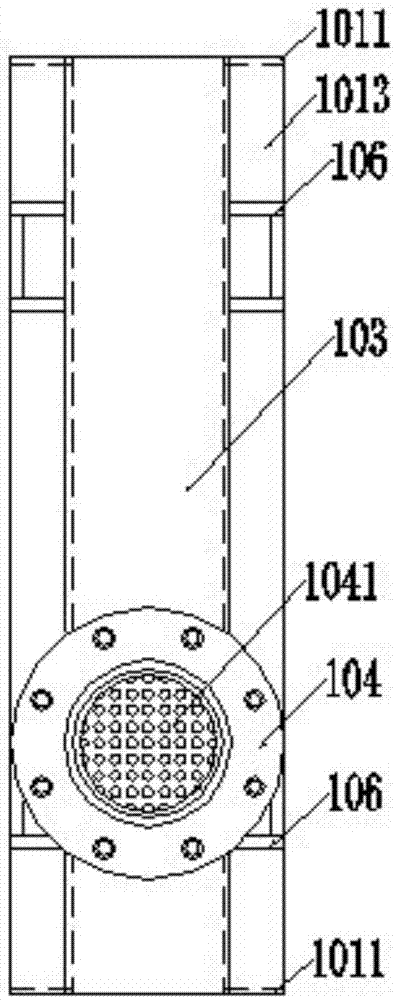

[0027] figure 1 It is the front view of the hydraulic oil cooler provided by Embodiment 1 of the present invention; figure 2 It is the left side view of the hydraulic oil cooler provided by Embodiment 1 of the present invention; image 3 It is the right side view of the hydraulic oil cooler provided by Embodiment 1 of the present invention; Figure 4 It is a top view of the hydraulic oil cooler provided by Embodiment 1 of the present invention; as shown in the figure, the hydraulic oil cooler provided by Embodiment 1 of the present invention includes: a cooling body 101 with a built-in cooling core 00, and the left side of the cooling body 101 The middle part is packaged with a left head 102, and the middle part of the right side of the cooling body 101 is packaged with a right head 103. The top, bottom, front and back of the cooling body 101 are all a thin plate 1011, and the left side of the cooling body 101 is front and rear. The parts on both sides are left strip-shaped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com