Ultrasonic sensor base with damping spring device

A sensor base and shock-absorbing spring technology, which is applied in the field of sensors, can solve problems such as poor shock absorption, and achieve the effect of reducing errors and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

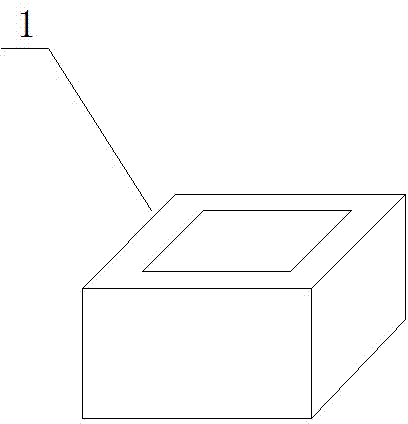

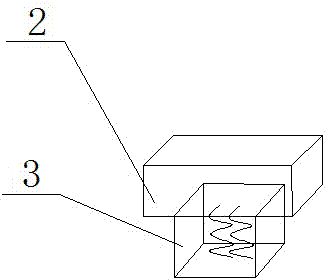

[0015] Such as figure 1 The ultrasonic sensor base with shock absorbing spring device provided in this embodiment includes a main body 1 and a sensor placement cavity 3 arranged in the main body 1. The main body 1 is made of rubber material. During the use of the ultrasonic sensor, It is unavoidable to be affected by its own vibration or surrounding mechanical vibration, which will further affect the accuracy of the ultrasonic sensor. The ultrasonic sensor base made of rubber provided by the present invention can effectively absorb vibration and ensure the measurement accuracy of the ultrasonic sensor.

Embodiment 2

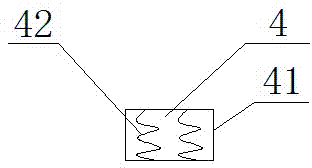

[0017] On the basis of Embodiment 1, this embodiment is provided with a placement cavity 3 that can accommodate the shock absorbing spring device 4 directly below the sensor placement cavity 2. The shock absorbing spring device 4 includes a housing 41 and is installed in the housing 41. The three compression springs, the axis of the three compression springs are perpendicular to the bottom surface of the body, the ultrasonic sensor base with the shock absorbing spring device provided by the present invention can timely and effectively reduce the vibration brought by the ultrasonic sensor or the surrounding machinery Absorb and reduce the error caused by vibration to ensure the accuracy of the ultrasonic sensor.

[0018] The base of the ultrasonic sensor provided by the present invention has a shock-absorbing effect, can effectively reduce errors caused by vibration, and ensure the measurement accuracy of the ultrasonic sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com