System and method for controlling a vision-guided robotic assembly

A technology of robots and robot arms, applied in the directions of robots, program-controlled manipulators, control using feedback, etc., can solve the problem of time-consuming capture and processing of visual images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

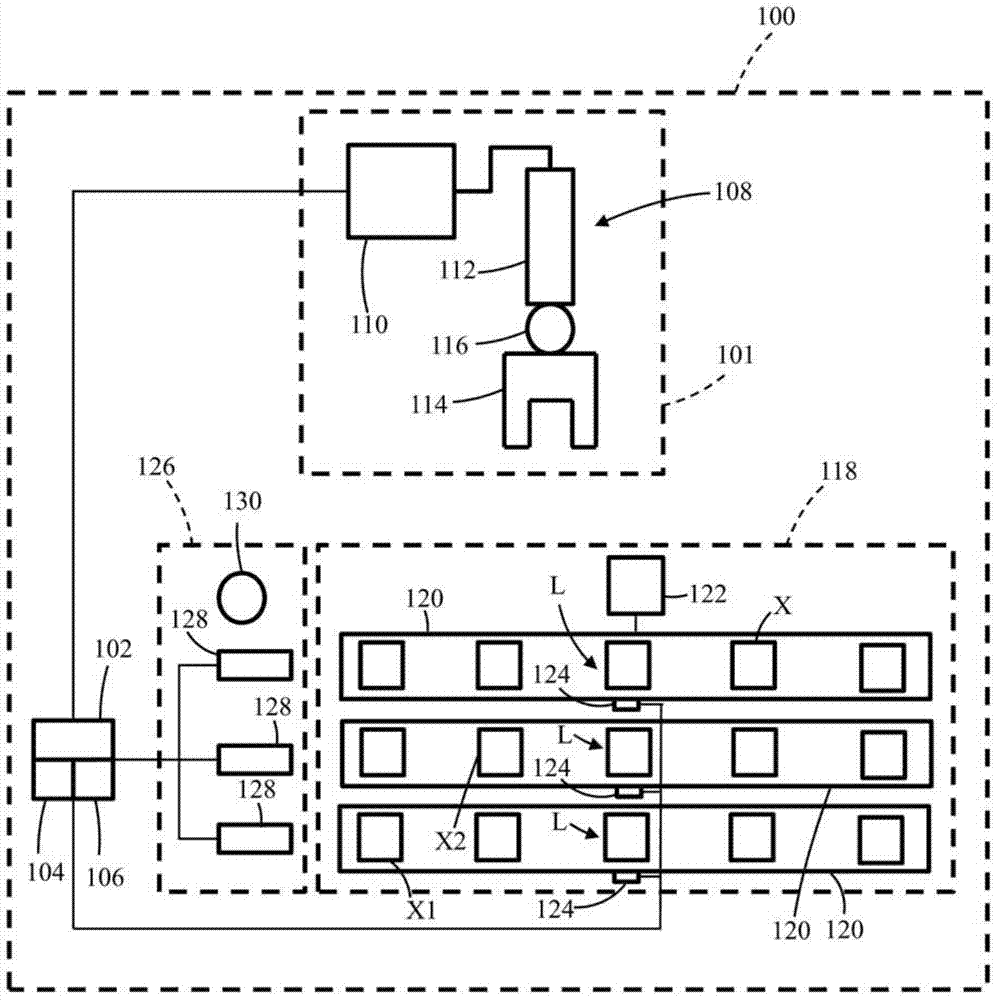

[0018] Referring to the drawings, like reference numerals correspond to like or similar parts throughout the several views, figure 1 A system 100 for assembling a device consisting of a plurality of parts X, such as a battery, is schematically illustrated. System 100 includes a system controller 102 having at least one processor 104 and at least one memory 106 (or any suitable non-transitory computer-readable storage medium). Processor 104 may be a combination of application specific integrated circuit(s), circuit(s), and central processing unit(s) (ie, microprocessor). Memory 106 may be a combination of one or more of read-only memory, read-only programmable memory, random access memory, hard drive, or other suitable non-transitory computer-readable storage media. Processor 104 may execute controller-executable instructions stored in memory 106 . Controller-executable instructions may be software or firmware routines or routines, combinational logic circuit(s), serial logic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com