A red fluorescent glue solid crystal led filament

An LED filament, red fluorescent technology, applied in the cooling/heating device of lighting device, lighting device, lighting and heating equipment, etc., can solve the problems of blue light leakage of LED filament, poor filament heat dissipation and light output effect, etc., to increase optical reflection , Good heat dissipation performance, avoid the effect of insufficient thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

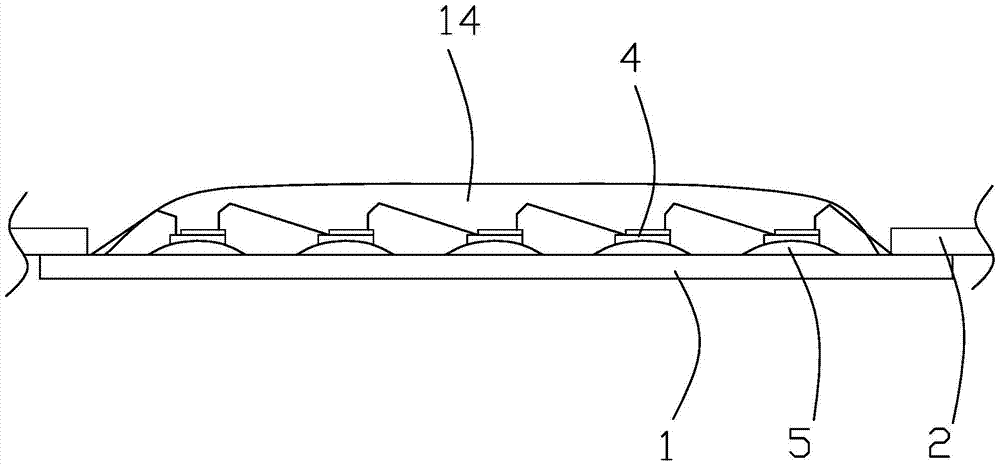

[0022] In this embodiment, a red fluorescent glue solid crystal LED filament, such as figure 1 As shown, a transparent substrate 1 is included. A number of LED chips 4 are arranged on one side of the substrate. The LED chips are fixed on the substrate by a fluorescent glue layer 5, which is filled between the LED chip and the substrate and wraps around the LED chip. The LED chips are connected by gold wires, and a sealing glue layer 14 is wrapped around the LED chips and the fluorescent glue layer.

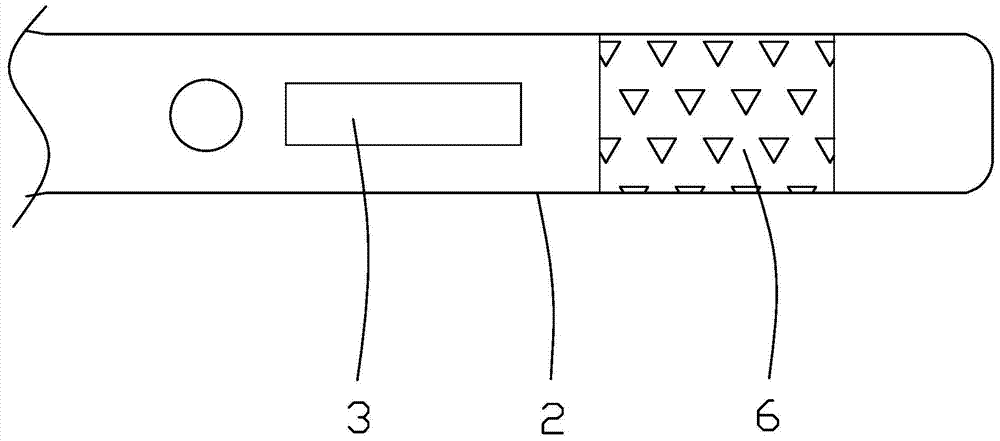

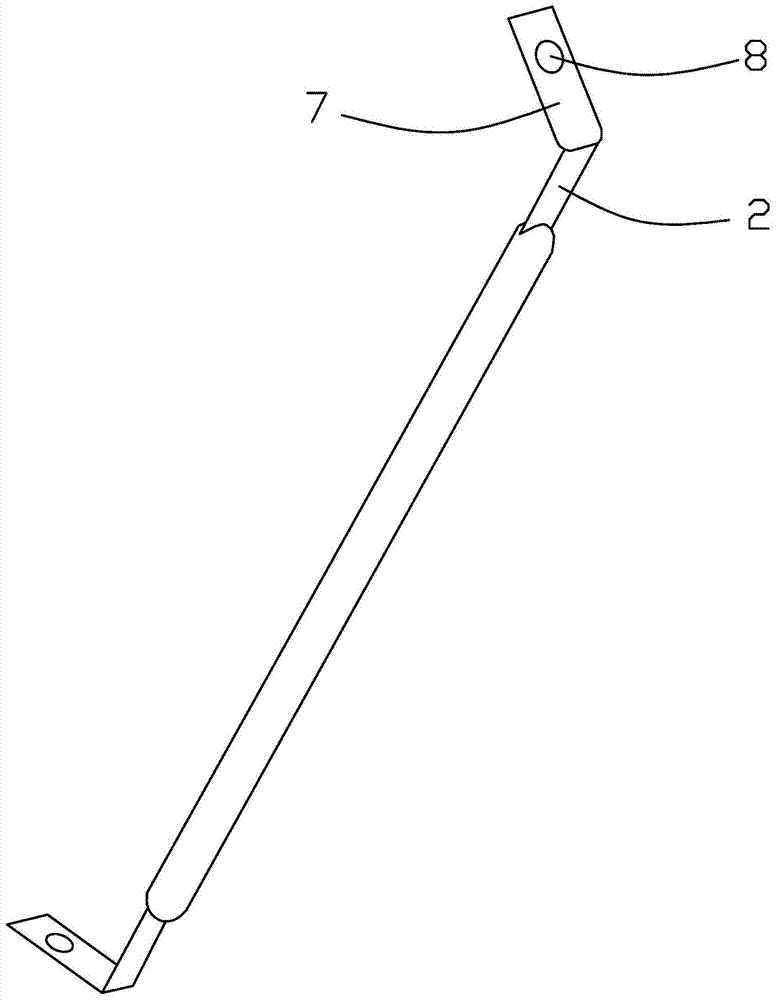

[0023] The two ends of the substrate are connected with metal sheets 2, such as figure 2 As shown, a roughened area 6 is provided on the surface of the metal sheet near the rear end, and the roughened area is a structure using any one or a combination of bumps, pits, printing, pressing lines or blister copper. Strip holes 3 are also opened in the metal sheet.

[0024] Such as Figure 4 As shown, a number of heat dissipation holes 9 are provided along the length of the substrate, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com