Steel plate

A technology of steel plate and plate thickness, applied in the direction of furnace type, furnace, heat treatment furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

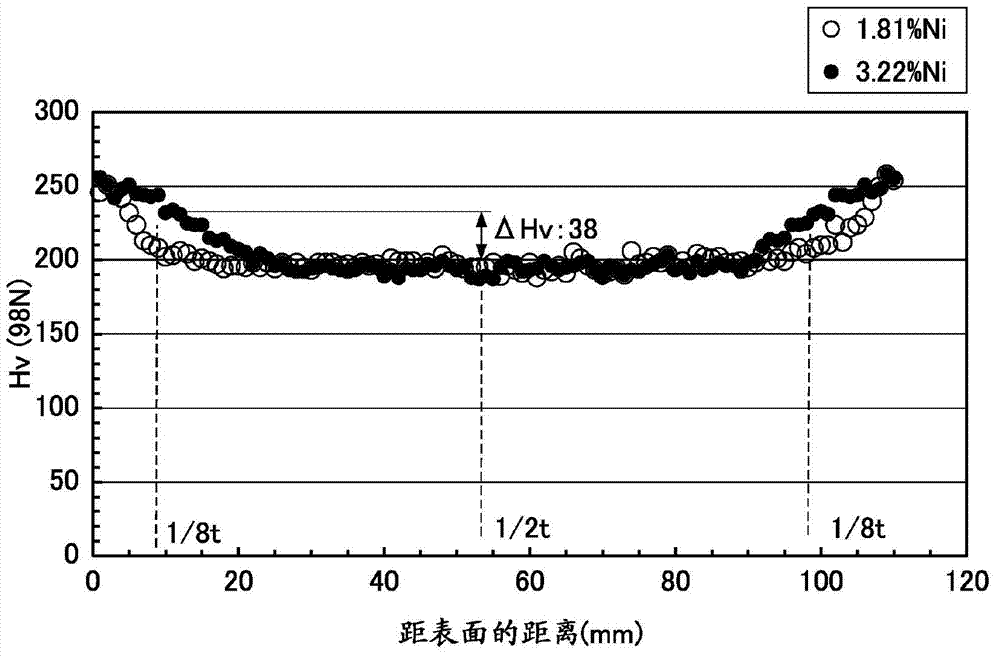

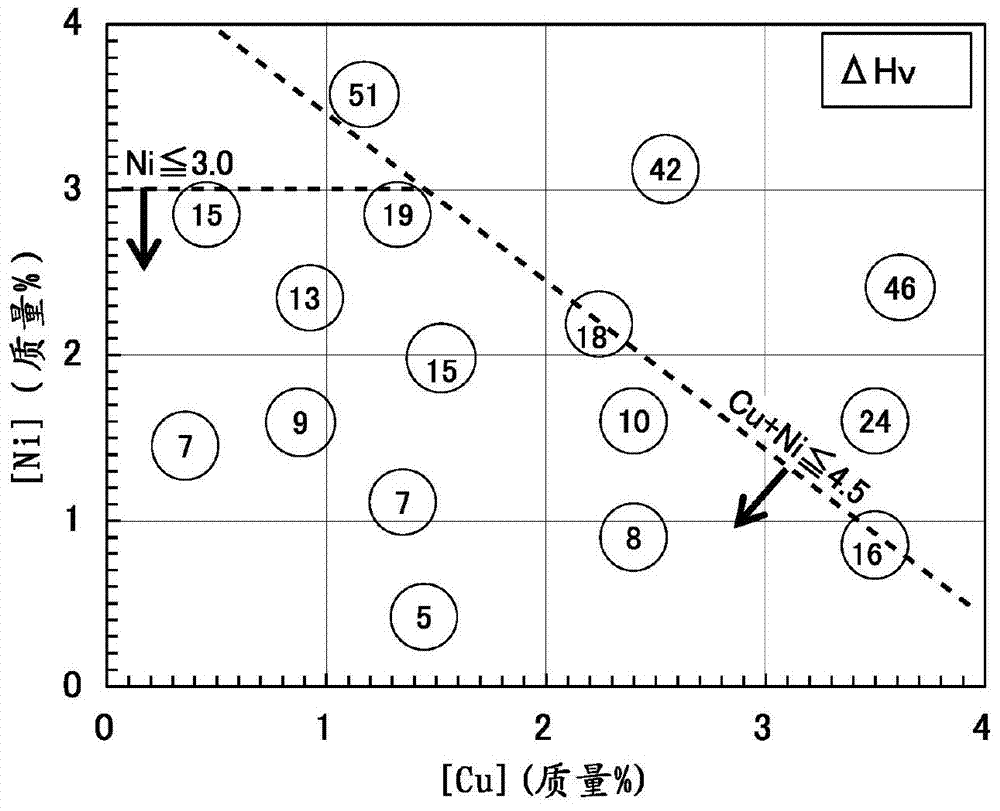

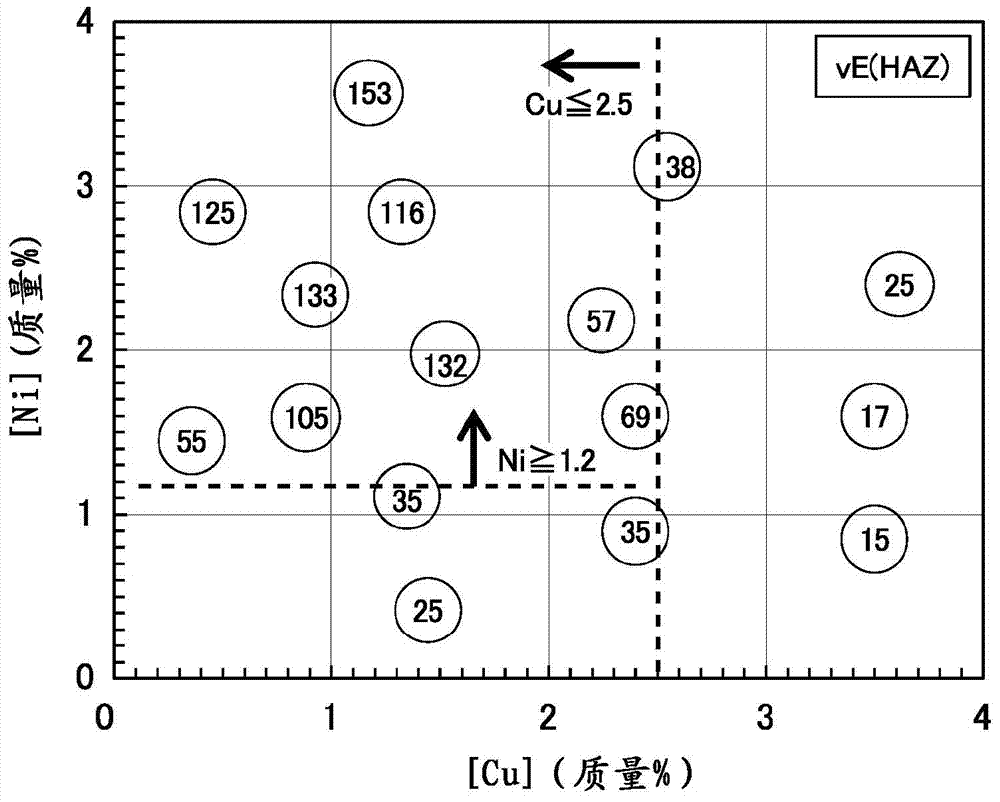

[0125] The steel sheets obtained by melting the steels A1-A10 and B1-B29 having the composition shown in Table 1 and Table 2 are formed into steel plates with a thickness of 80-200 mm under the manufacturing conditions shown in Table 3 and Table 4 .

[0126] In production, the heating temperature is 950° C. to 1250° C., and after that, hot rolling is performed, followed by air cooling or water cooling. Then, for test numbers 5, 10, 15, and 26, preheating treatment was performed before quenching treatment. With respect to the steel plates of test numbers 1 to 51, except for test number 18, quenching and tempering treatments were performed. In addition, in Test No. 18, water cooling was performed to 100° C. immediately after rolling, and only tempering was performed without quenching. Then, in order to evaluate the strength characteristics of the base material, a No. 14 tensile test piece specified in JIS Z 2201 was prepared, and a tensile test specified in JIS Z 2241 was perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com