Exhaust modules and reciprocating engines

An exhaust module, reciprocating technology, applied in the direction of engine components, combustion engines, machines/engines, etc., can solve problems such as turbocharger operation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

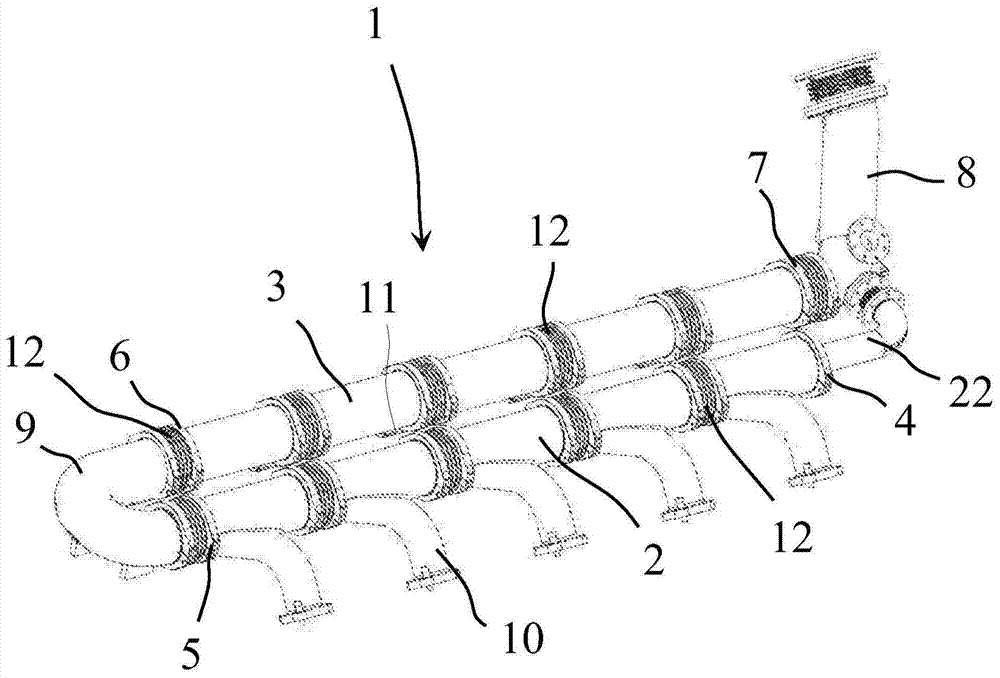

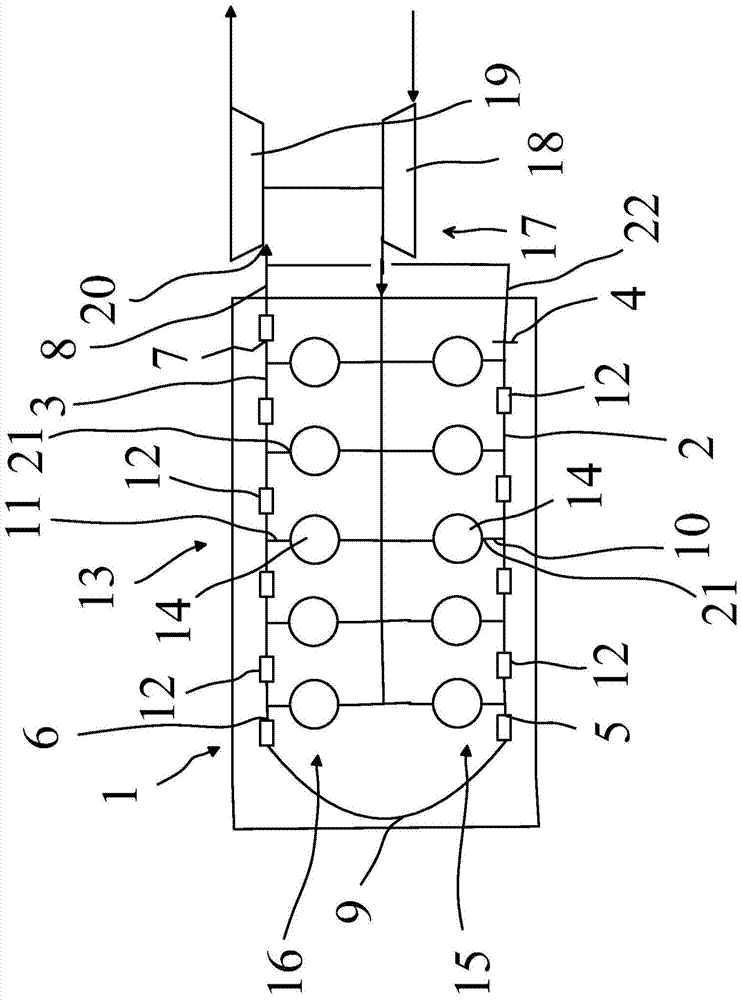

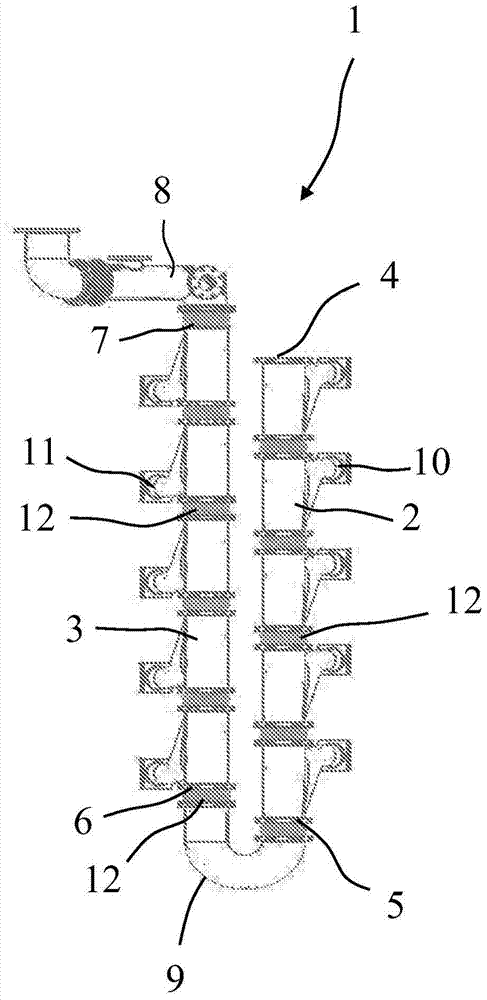

[0010] figure 2 and Figure 4 A reciprocating engine 13 having several cylinders 14 is disclosed. The cylinders 14 are arranged in two groups 15, 16 in a V-shaped configuration. The engine may be a large reciprocating engine. A large reciprocating engine here refers to such an engine that can be used, for example, as a main engine and an auxiliary engine in a ship or a power station for generating heat and / or electricity. Engine 13 includes a turbocharger 17 having a compressor 18 and a turbine 19 . Exhaust gases from cylinders 14 in the first cylinder bank 15 and the second cylinder bank 16 are arranged to pass through a turbine 19 .

[0011] The engine 13 is provided with an exhaust module 1 for connecting the cylinders 14 to a turbine inlet 20 . exist figure 2 and Figure 4 The structure of the exhaust module is shown in more detail in . The exhaust module 1 comprises a first exhaust manifold 2 for receiving exhaust gases from cylinders of a first cylinder bank 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com