Cascade thrust reverser for an aircraft turbofan

A thrust reverser and blade cascade technology, which can be used in machine/engine, jet propulsion, etc., to solve problems such as aerodynamic flow quality and hinge wear that affect cold air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

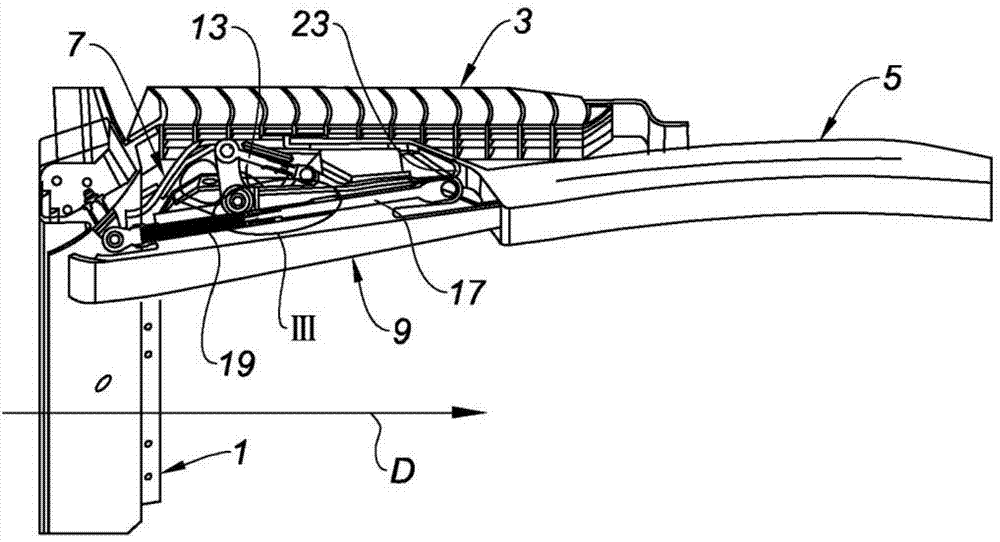

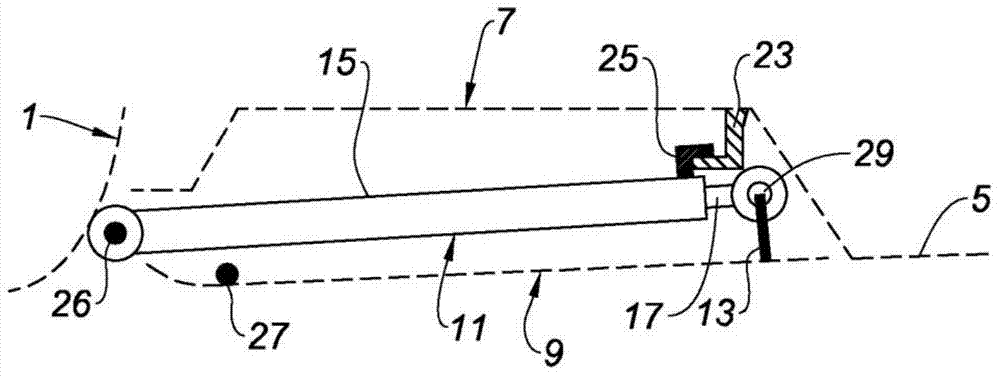

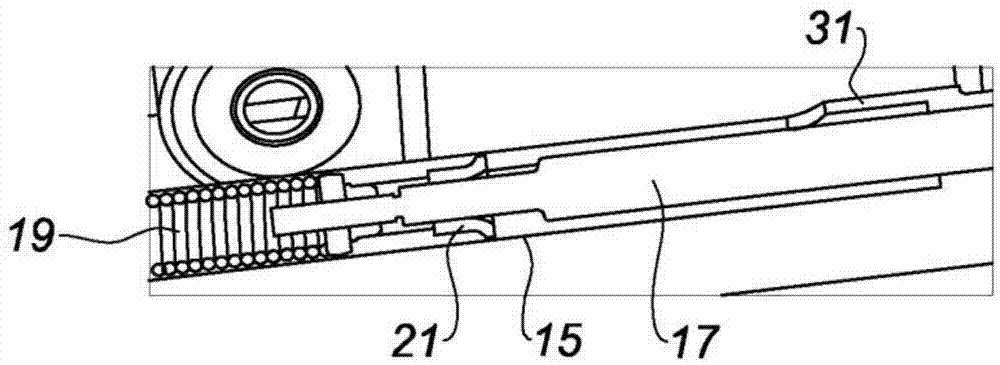

[0036] like figure 1 As shown, the thrust reverser of the present invention comprises a fixed front frame 1 integral with the fan housing of the turbojet engine (not shown).

[0037] A fixed front frame 1 defining a substantially annular shape supports a plurality of deflecting cascades 3 arranged side by side at the edges of the front frame.

[0038] Its upstream portion of the sliding cover 5 includes a housing 7 movable between a direct spray position and an indirect spray position, as in figure 1 The casing 7 covers the deflection cascade 3 in the direct injection position shown, while the Figure 9 In the position of the indirect injection shown in , the casing 7 exposes the deflection vanes 3 .

[0039] Inside the shell 7 of the sliding cowl 5 are mounted side by side a plurality of thrust reverser baffles 9 which are pivotally mounted on such as figure 1 direct injection position shown and as Figure 9 Between the reverse injection positions shown, in which the thru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com