Electrode arrangement for an impeded plasma

A technology of electrode assembly and plasma, which is applied in the direction of plasma, electrical components, parts of surgical instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

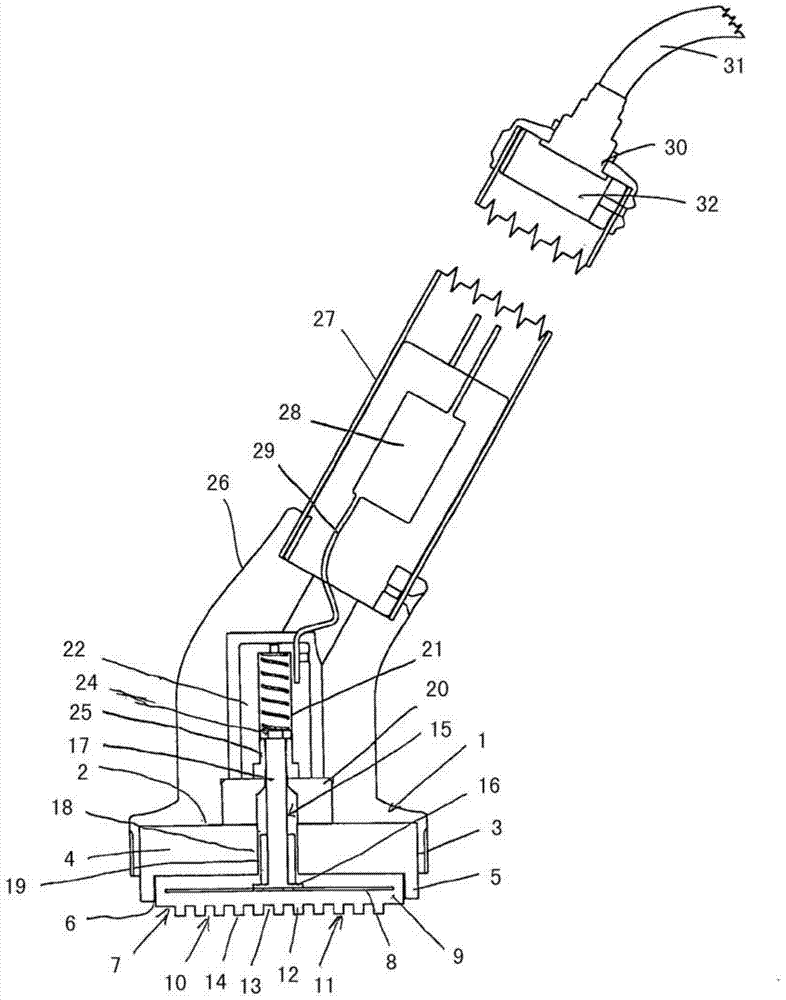

[0015] The single illustration shows a housing part 1 which is pot-shaped and has a planar bottom wall 2 and a cylindrical, surrounding housing wall 3 . The housing part 1 can have a circular, rectangular or polygonal cross-section. The housing part 1 is designed to be open on the side opposite the bottom wall 2 and thus serves as a receptacle for a pressure means 4 for surface elasticity in the form of a one-piece elastic material. The block is made, for example, of a preferably soft elastic foamed plastic.

[0016] On the side facing away from the bottom wall 2 , the elastic pressing means 4 are provided with a large-area recess which forms a receiving chamber 6 delimited by a surrounding edge 5 . An electrode element 7 comprising a planar electrode 8 which is surrounded on all sides by a planar and flexible dielectric 9 is inserted into the receiving chamber 6 which is open on one side. The dielectric 9 protrudes with an active surface 10 beyond the edge 5 of the pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com