Deep-cone thickener

A technology of deep cone thickener and cone platform, which is applied in the direction of settling tank, feeding/discharging device of settling tank, chemical instruments and methods, etc. It can solve the problem of poor adjustability of equipment parameters, inability to adapt to production needs, and low settling efficiency and other problems, to achieve the effect of strong adjustability, simple structure and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] Deep cone thickener of the present invention, its preferred embodiment is:

[0023] Including tank body, large cone, small cone, rake frame, feeding device, rake frame lifting drive device;

[0024] The tank body is a cylindrical structure with flanges on the upper and lower ends respectively, and the large diameter end of the large cone is connected upwardly with the flange at the lower end of the tank body through the flange. The small-diameter end of the large cone is downwardly connected with the large-diameter end of the small cone, and the small-diameter end of the small cone is provided with a discharge port and a valve device;

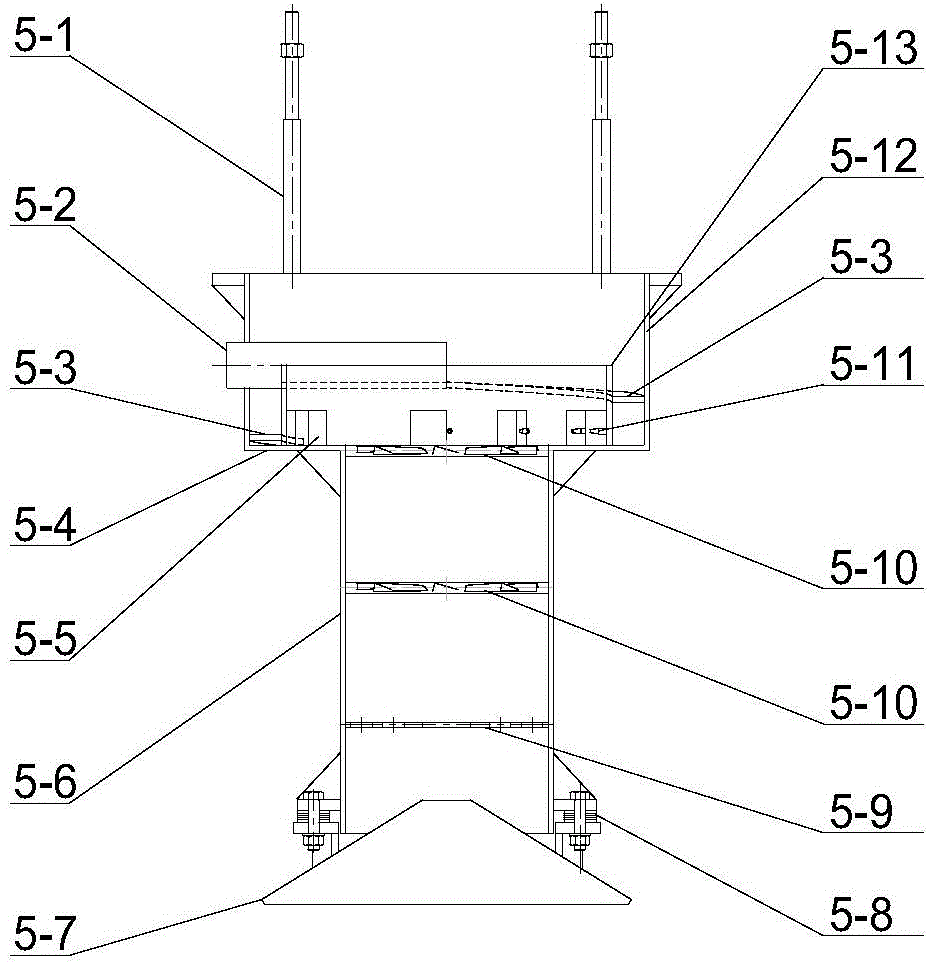

[0025] The upper flange of the trough is connected to the rake lifting drive device, the main shaft of the rake lifting drive device is connected to the central drive shaft of the rake, and the upper end of the feeding device is connected to the rake through a screw. The lifting plate of the rake frame lifting drive is connected.

[00...

specific Embodiment

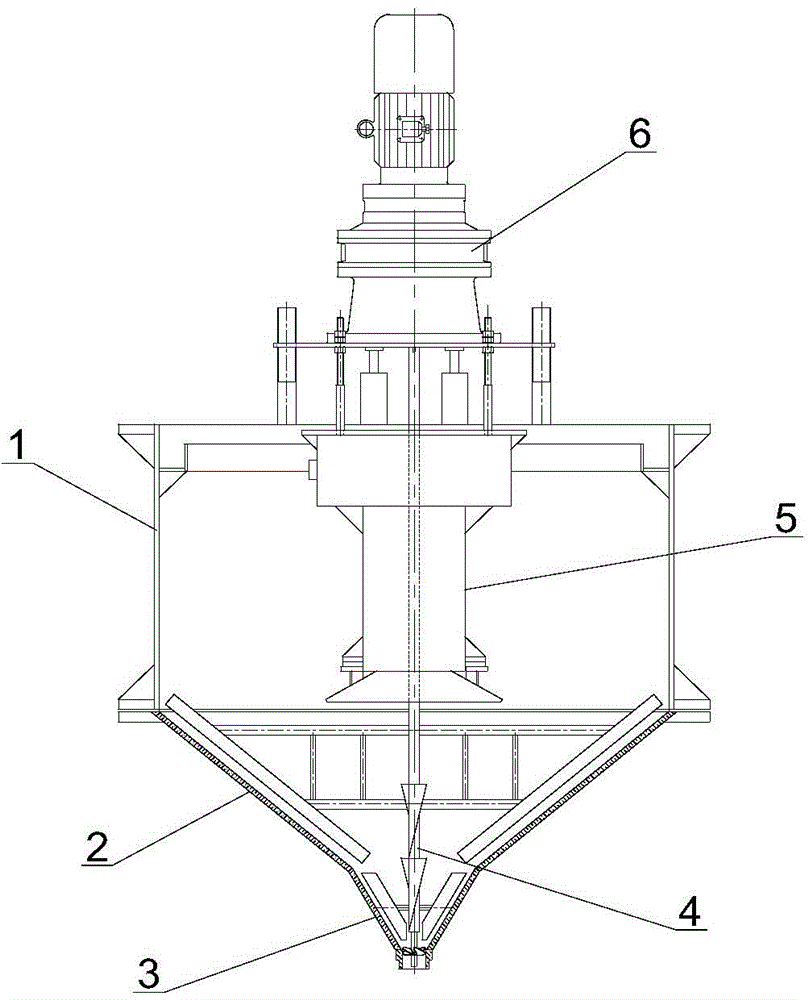

[0032] Such as Figure 1 to Figure 4 As shown, it is mainly composed of a tank body 1, a large cone 2, a small cone 3, a rake frame 4, a feeding device 5, and a rake frame lifting drive device 6.

[0033] The tank body 1 is a cylindrical structure with connecting flanges at the upper and lower ends; the large diameter end of the large cone 2 is connected upwards with the lower end of the tank body 1 through the flange, and the small diameter end of the large cone 2 is downward It is connected with the large-diameter end of the small cone 3, and the small-diameter end of the small cone 3 is generally connected with a valve device.

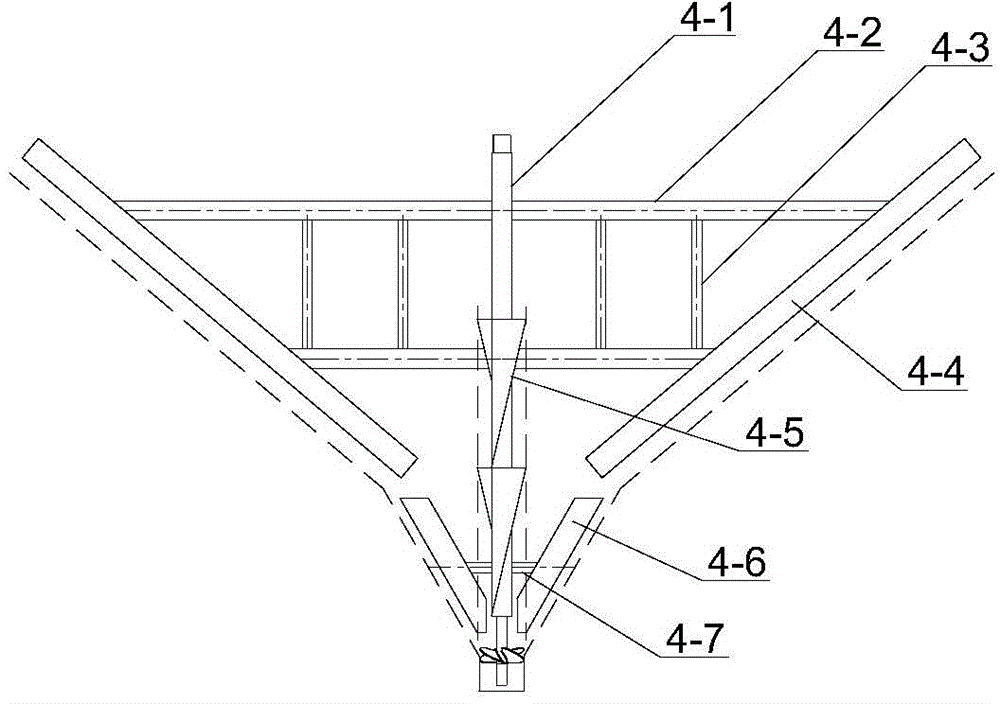

[0034] The independent scheme of the rake frame 4 is: the central transmission shaft 4-1 is a vertical transmission shaft, the upper end of which is threaded and connected with the motor reducer, and the lower end is a thin shaft with a thinner diameter, which is inserted into the thickener during use. The ore discharge port of the trough; the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com