Automatic Control Mechanism of Tomato Peel Separator

A technology of tomato peel residue and separator, which is applied in the direction of solid separation, separation method, precipitation separation, etc., can solve the problem of inability to automatically control peel residue separation, etc., so as to improve the separation rate and separation cleanliness of peel residue, and reduce overflow loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

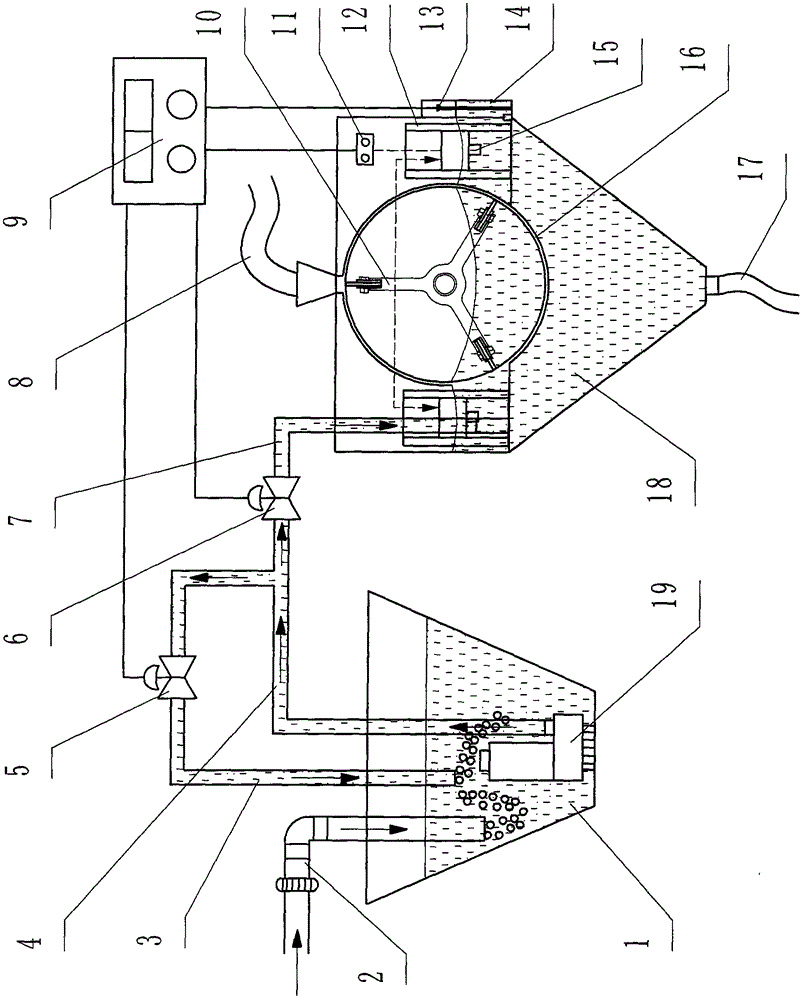

[0010] Embodiment: with reference to accompanying drawing, comprise overflow device, liquid level detection device, liquid level adjustment device, controller 9, feeding pipeline 8 and discharge pipeline 13; Described overflow device is composed of overflow tank 15, overflow Groove driving device 11, chute 12 and settling chamber 18 constitute, overflow groove 15 is located on chute 12, overflow groove driving device 11 can synchronously drive overflow groove 15 on both sides of settling chamber 18, on chute 12 Slide to control the liquid level in the settling chamber 18 of the tomato peel and residue separator, and transmit the liquid level information to the controller 9. The settling chamber 18 is equipped with a tomato peel and residue centrifugal screening drum 16, and the centrifugal screening drum 16 is A mesh is provided, a stirring scraper 10 is arranged in the centrifugal screening drum 16, the feeding pipeline 8 is for the continuous feeding of the centrifugal screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com