Mine crusher anti-resonance method and system thereof

A crusher and mining technology, applied in the field of mining machinery control, can solve the problems of reducing the service life of the crusher, unable to solve the problems of equipment resonance, large machinery and structure, etc., to avoid resonance phenomenon, improve service life, and enhance prediction ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

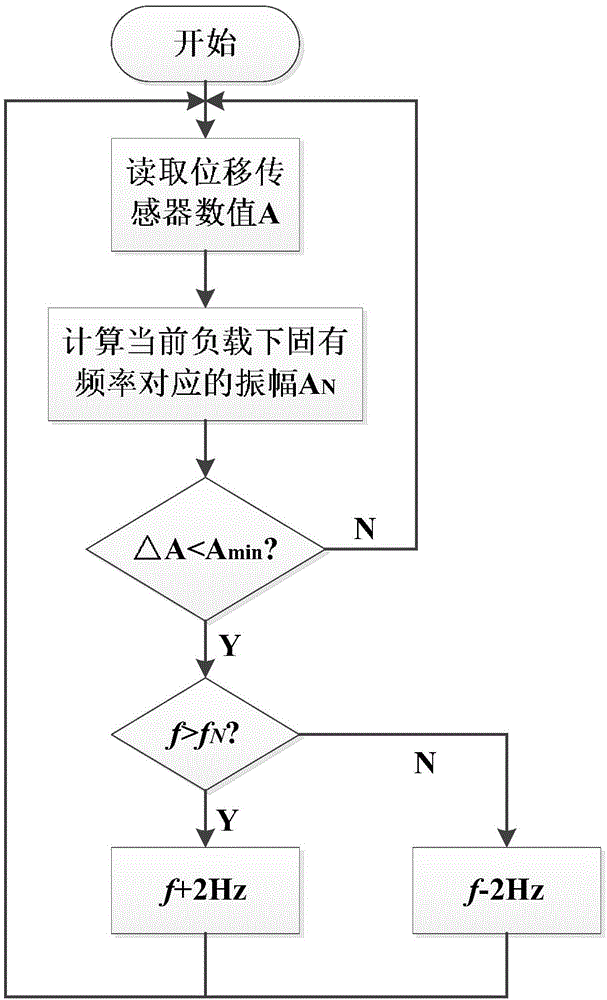

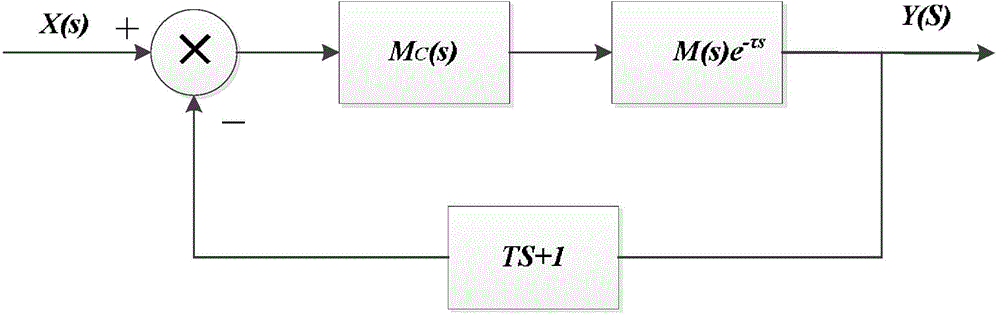

[0024] A method for anti-resonance of a mine crusher, comprising the following steps,

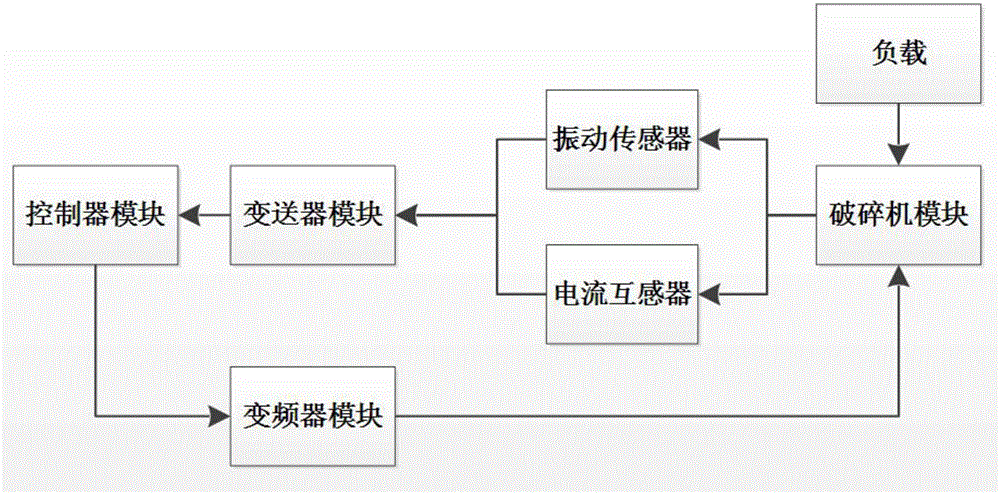

[0025] The first step: install the vibration sensor on the crusher body, and install the current transformer on the main circuit of the crusher motor;

[0026] The vibration sensor is a displacement sensor; the crusher motor provides external excitation frequency.

[0027] Step 2: Obtain the natural frequency of the crusher under different loads and the corresponding amplitude of the crusher, and establish a standard modal curve for input to the PLC controller; the steps for establishing a standard modal curve include:

[0028] The main transmission parts of the crusher are properly meshed, and the two ends of the transmission parts are fixedly supported, and the finite element model of each transmission part is constructed.

[0029] (2) The loading range of load L is 0L N -1.25L N ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com