Linear double-layer banana screen for mineral screening

A technology of mineral screening and banana sieve, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of short development time of banana sieve, lack of timely improvement, difficulty in shaping and promotion, etc., and reduce the negative impact of resonance force , cost-effective, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below through specific examples.

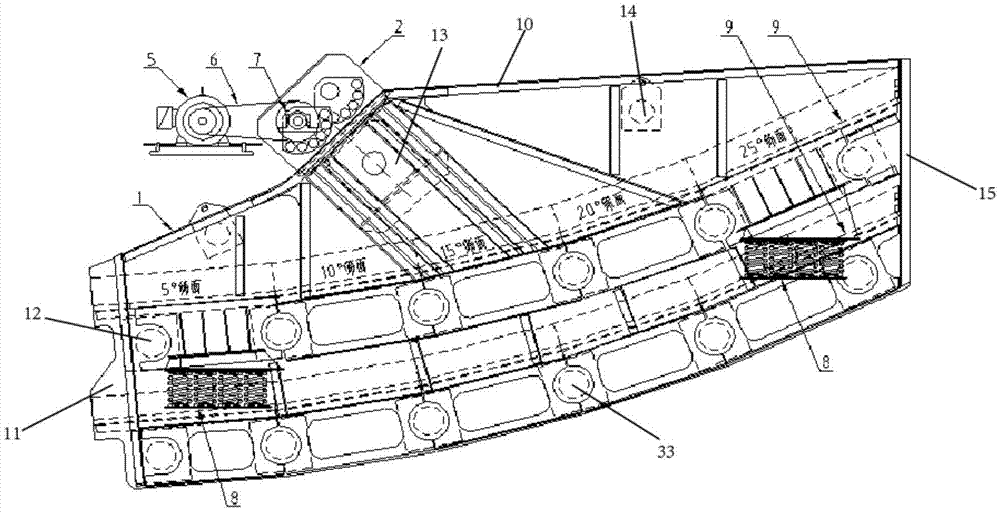

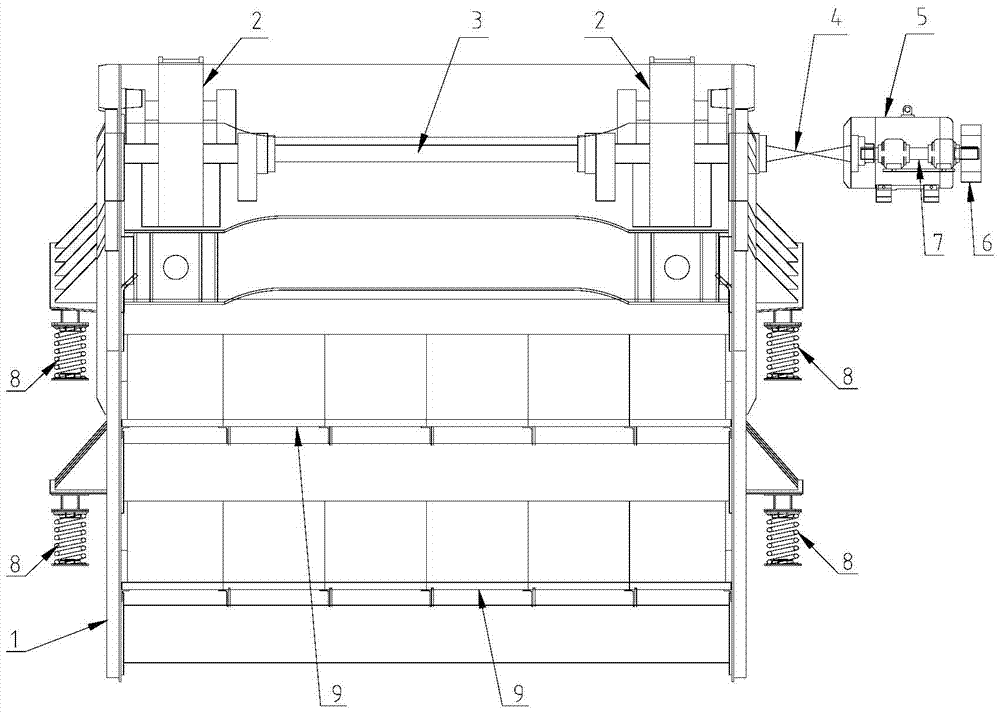

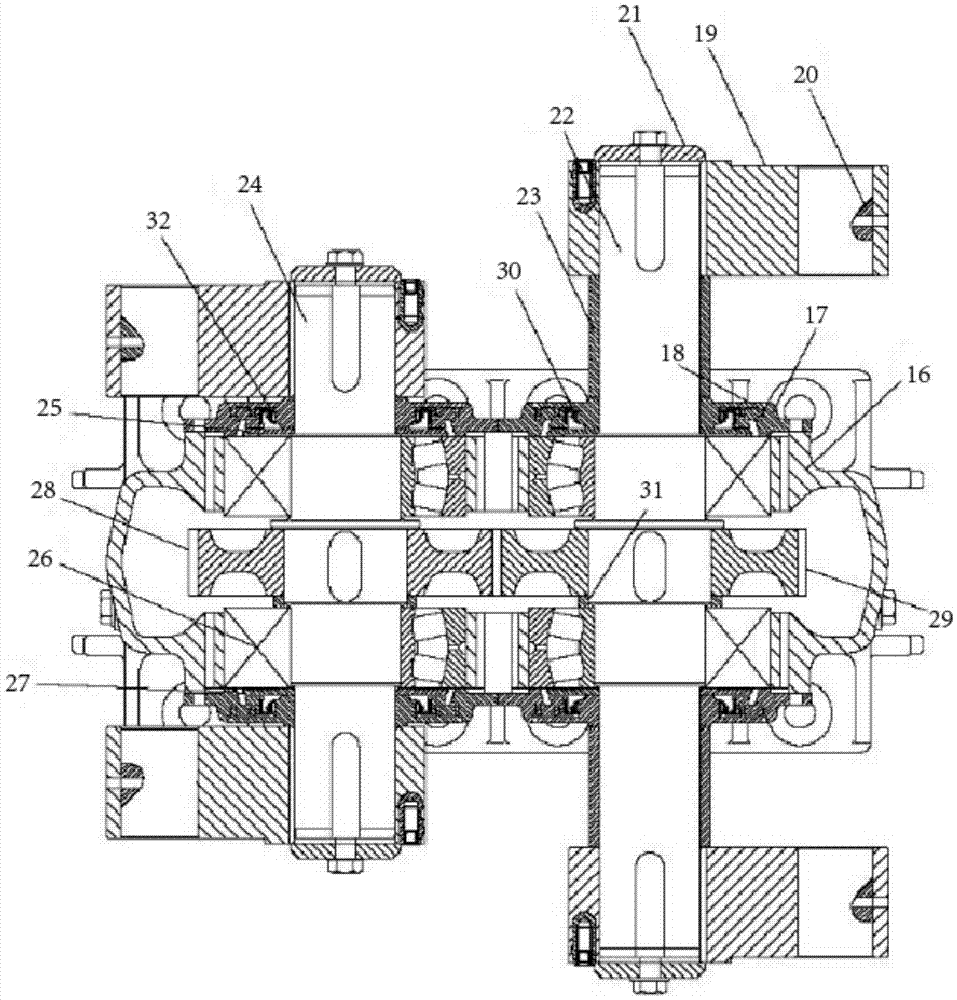

[0016] Such as Figure 1 to Figure 3 As shown, among them, 1 is the screen body, 2 is the screening vibrator, 3 is the connecting shaft of the vibrator, 4 is the driving connecting shaft, 5 is the vibration driving motor, 6 is the transmission device, and 7 is the driving device of the vibrator , 8 is the noise reduction buffer device, 9 is the screening device, 10 is the lifting beam installation part, 11 is the side mounting part, 12 is the upper beam, 13 is the excitation beam, 14 is the lifting beam, 15 is the back installation Plate, 16 is the box body, 17 is the bearing gland, 18 is the labyrinth seal ring, 19 is the pendulum block, 20 is the counterweight shaft, 21 is the pendulum block gland, 22 is the long axis, 23 is the pendulum block spacer sleeve, 24 25 is the first oil retaining plate, 26 is the bearing, 27 is the second oil retaining plate, 28 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com