Cyclone separator with gradually enlarged inlet, flow guide plate and dustproof screen and experiment system

The technology of a cyclone separator and an experimental system, which is applied in the direction of a device whose axial direction of the cyclone can be reversed, a cyclone device, etc., can solve the problems of unfavorable energy saving and emission reduction, affecting the efficiency of the separator, etc., so as to prevent escape and improve treatment. quantity, and the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention provides a cyclone separator and an experimental system with a gradually expanding inlet, a deflector and a dust-proof net. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

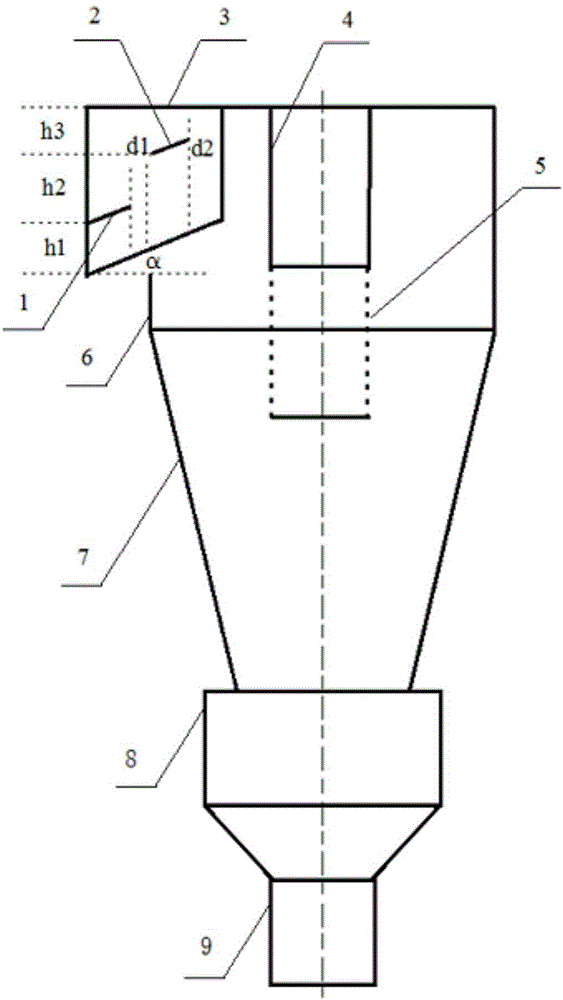

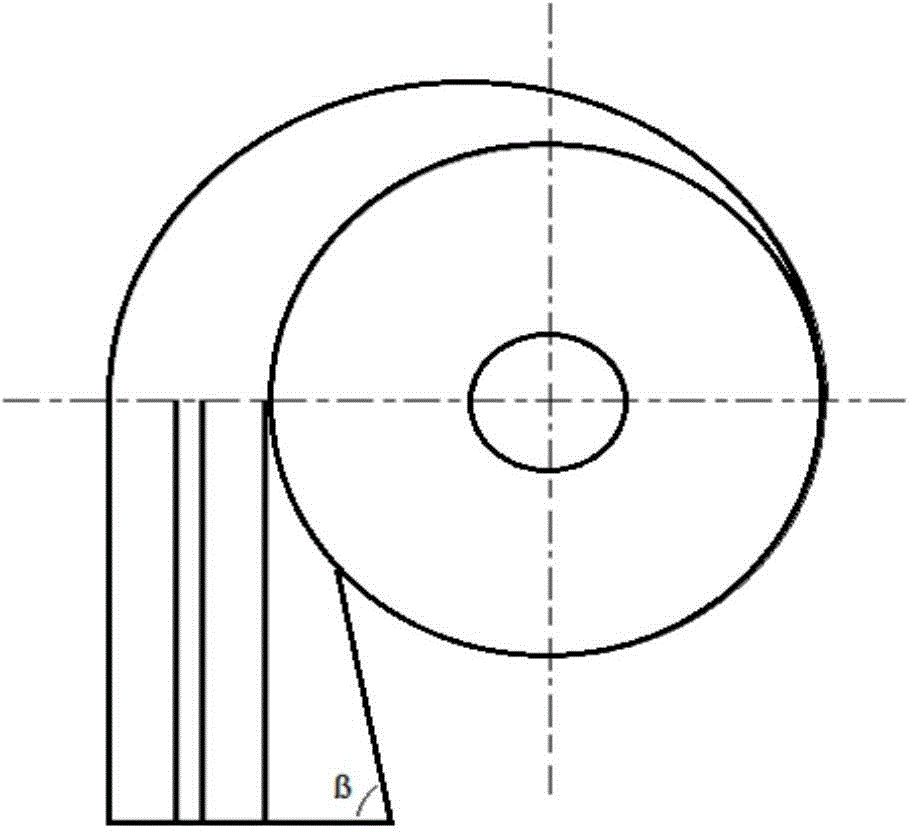

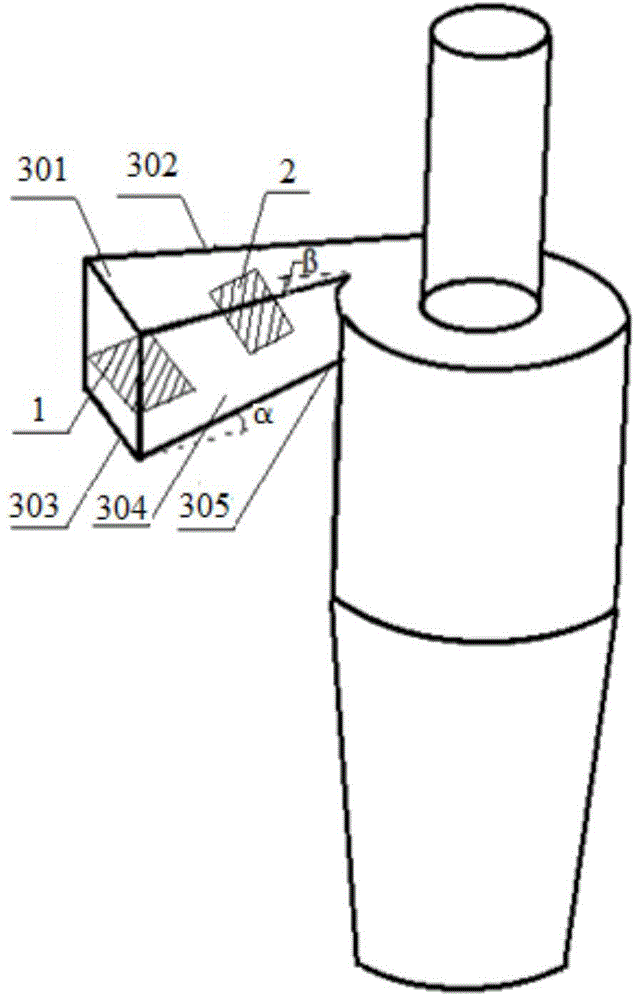

[0031] Such as figure 1 As shown, the cyclone separator includes a gradually expanding inlet 3, a central exhaust pipe 4, a separation cylinder 6, a cone cylinder 7 at the lower part of the separation cylinder, an ash hopper 8 and a dipleg 9. Gradually expanding inlet 3 is made up of top wall surface 301, outer wall surface 302, inlet wall surface 303, inner wall surface 304, bottom wall surface 305, top wall surface 301 is a horizontal plane, outer wall surface 302 is parallel to the cut surface of separation cylinder 6, and inlet wall surface 303 is a vertical plane. In a straight plane, the inner wall surface 304 slopes from outside to inside to the outside wall surface 302 , and the bottom wall su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com