Method and device capable of stably guiding welding wire out

A welding wire and stable technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of wire guide wheel and welding wire wear, large welding gun weight and volume, wire skipping, etc., to achieve stable wire feeding speed, welding Good road effect and uniform wire feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

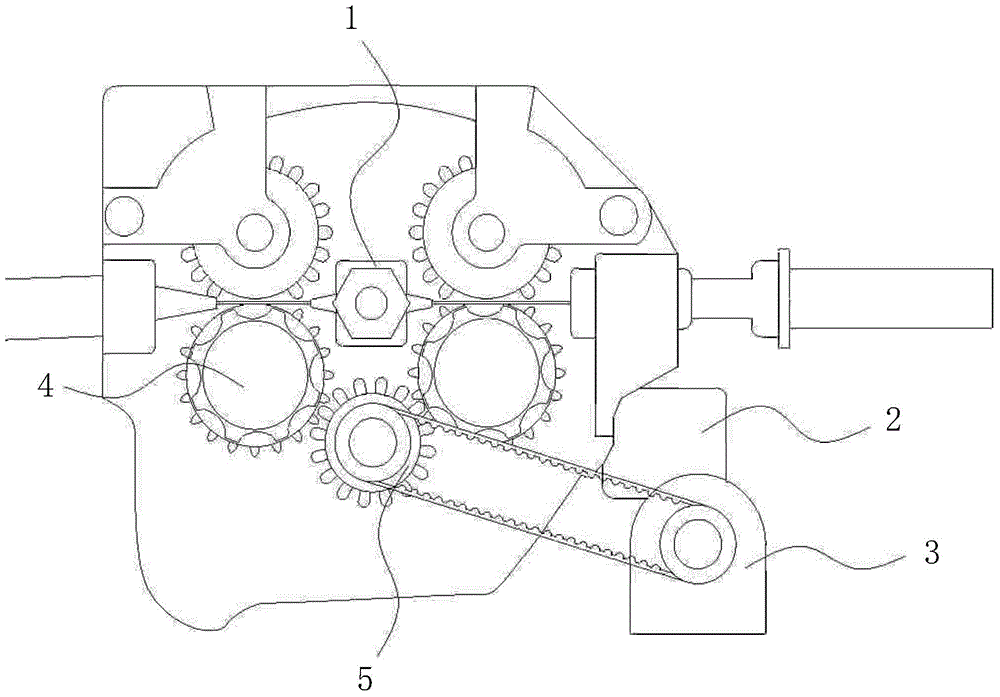

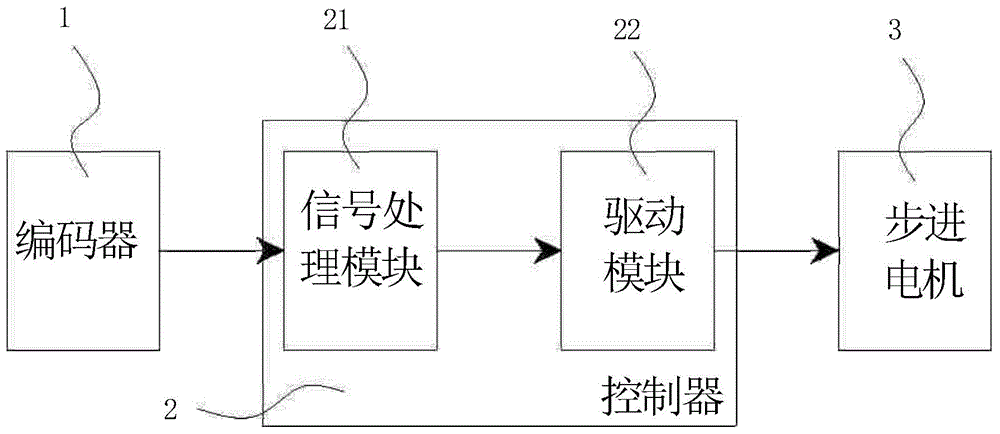

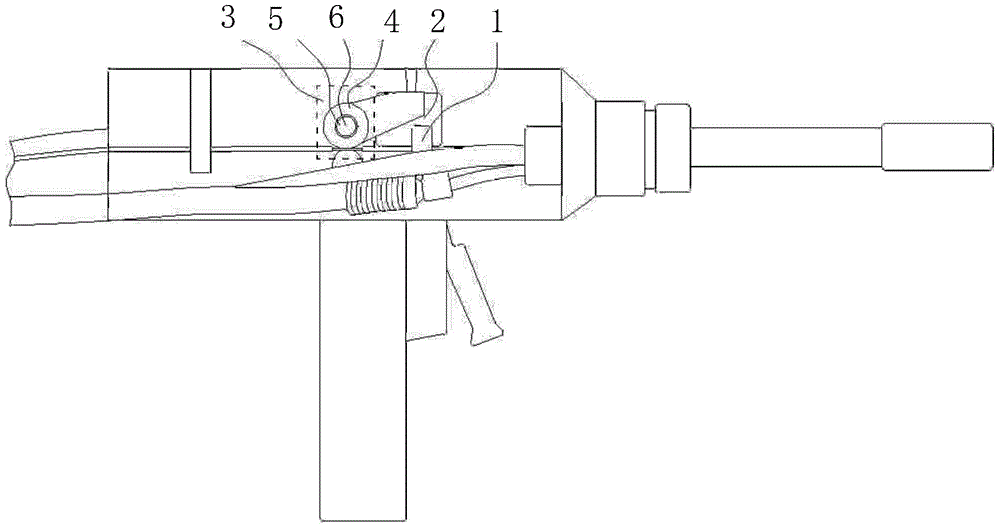

[0033] refer to image 3 As shown, a device that can stably lead out welding wire in this embodiment is arranged on a welding torch, and includes an encoder 1, a controller 2, a stepping motor 3 and a traction wheel set 4, and the encoder 1 is located in the conveying direction of the welding wire. The traction wheel group 4 is made up of a pair of traction wheels, and the traction wheel group 4 is symmetrically arranged on both sides of the welding wire, and the stepper motor 3 is connected with the power of the traction wheel group 4 through the transmission mechanism 5, and the transmission mechanism 5 is a power extension shaft 6, and the stepping motor 3, the power extension shaft 6 drives the traction wheel group 4 to rotate in the opposite direction of welding wire transmission, the signal output end of the encoder 1 is connected to the signal input end of the controller 2, and the signal output end of the controller 2 is connected to the stepping motor 3 signal input t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com