A Mechanical Vibration Friction Heat Generation Fusion Splicer

A technology of mechanical vibration and welding machine, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of uneven welding force of pipe fittings, affect the welding quality of products, increase welding costs, etc., and improve welding quality and welding efficiency , The model is compact, and the effect of welding force is uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the above.

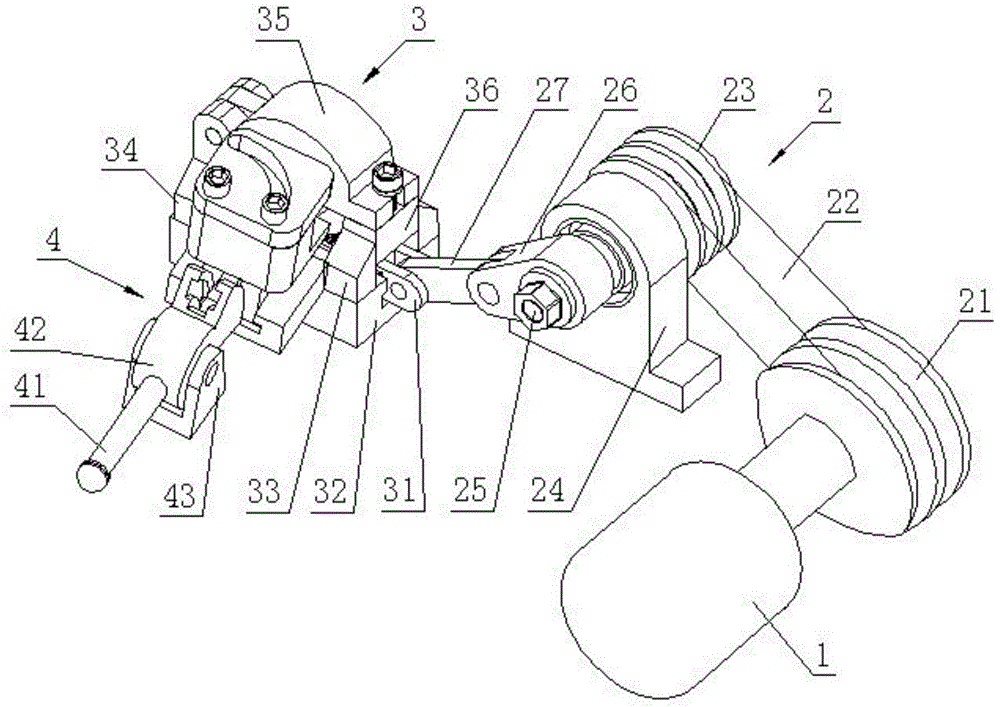

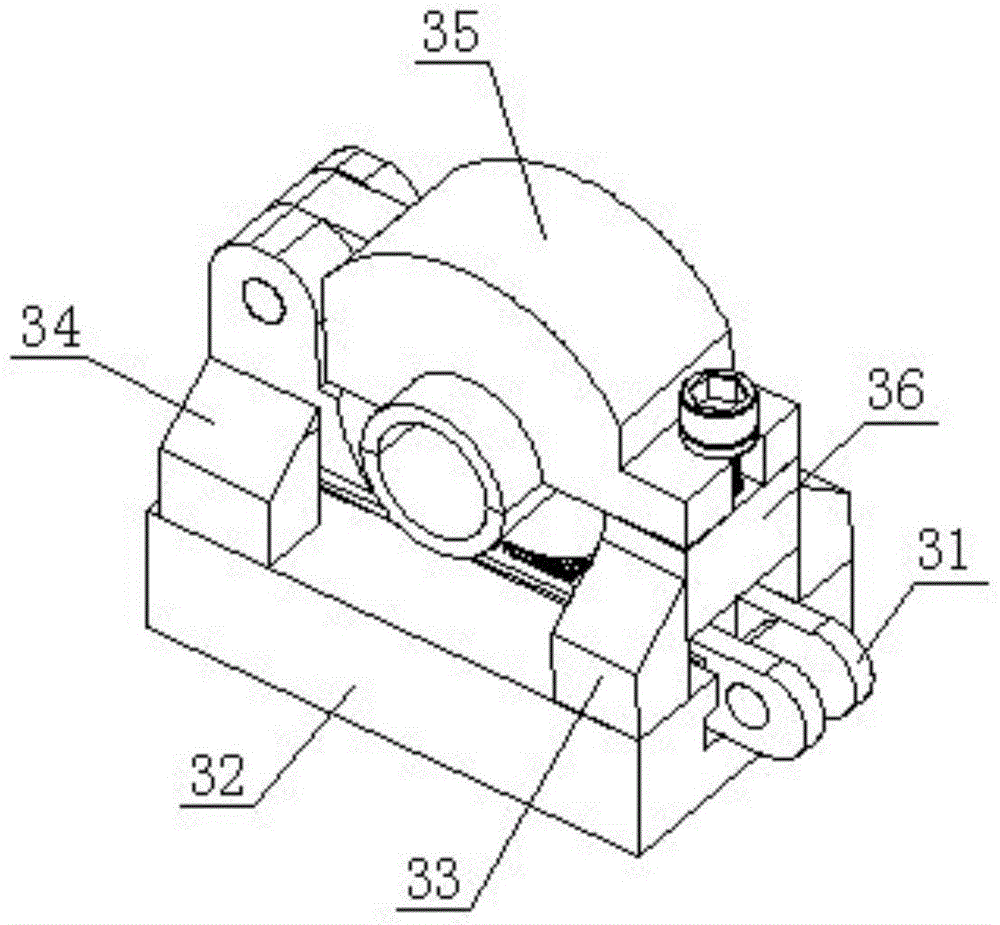

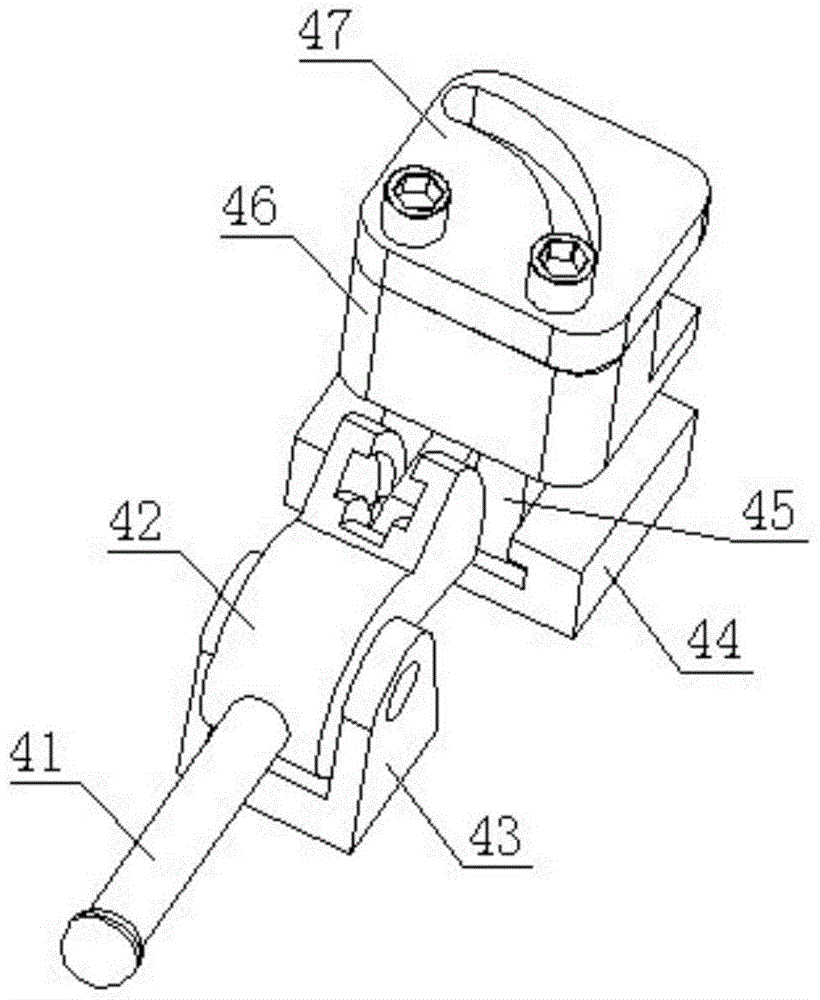

[0022] Such as Figure 1 to Figure 3 As shown, the mechanical vibration friction heat generating type welding machine according to the present invention is mainly composed of a driving motor 1, a power transmission mechanism 2, a friction heat generating welding mechanism 3 and an axial force applying mechanism 4. The driving motor 1 The output end is connected to the power transmission mechanism 2. The power transmission mechanism 2 is connected to the friction heat generating welding mechanism 3 through the transmission connecting rod 27. The axial force applying mechanism 4 is installed on the side of the friction heat generating welding mechanism 3, and the shaft The center line of the force applying mechanism 4 and the center line of the plastic pipe to be welded are installed on the same s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com