An image system laminating machine

A technology of an image system and a laminating machine, which is applied in the directions of lamination device, lamination auxiliary operation, lamination, etc., can solve the problems of waste of human resources, low work efficiency, and no device for detecting unqualified products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

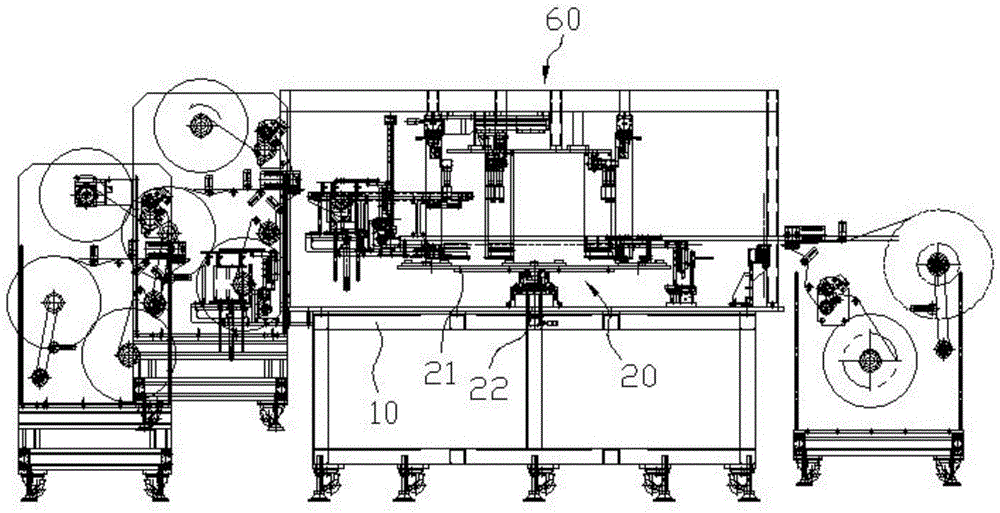

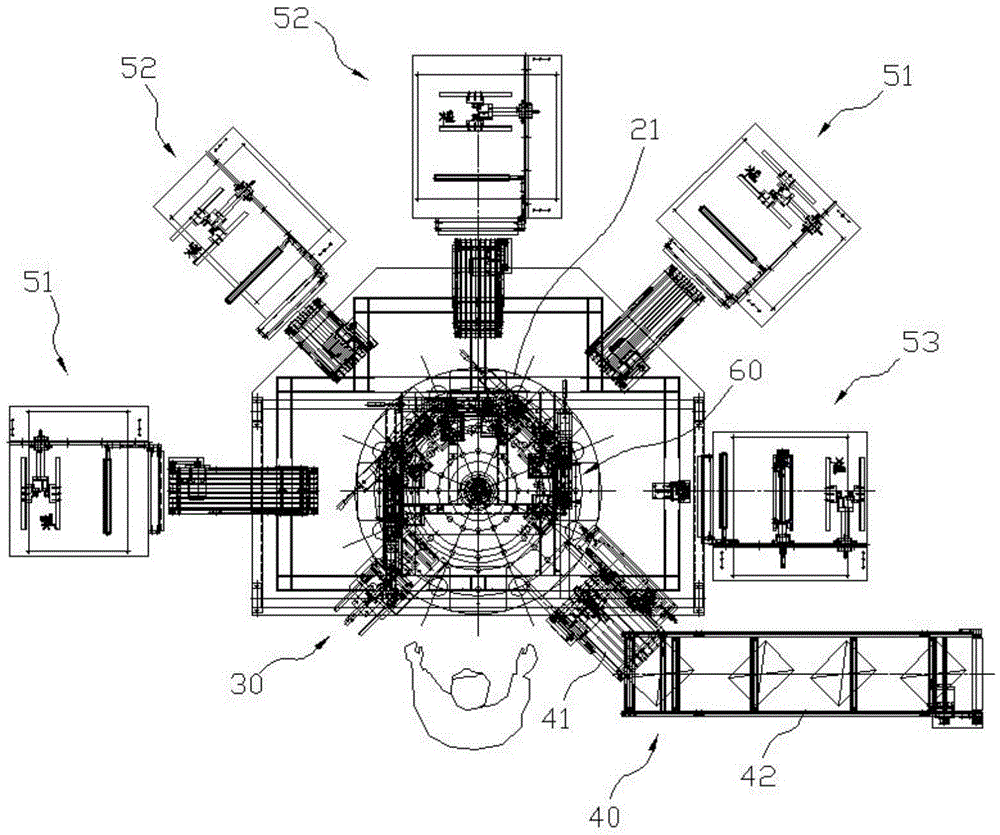

[0041] combine figure 1 , figure 2 , an image system film laminating machine, including a frame 10, a product conveying device 20, a dust removal device 30, a film laminating device, a finished product removal mechanism 40, and an image system 60.

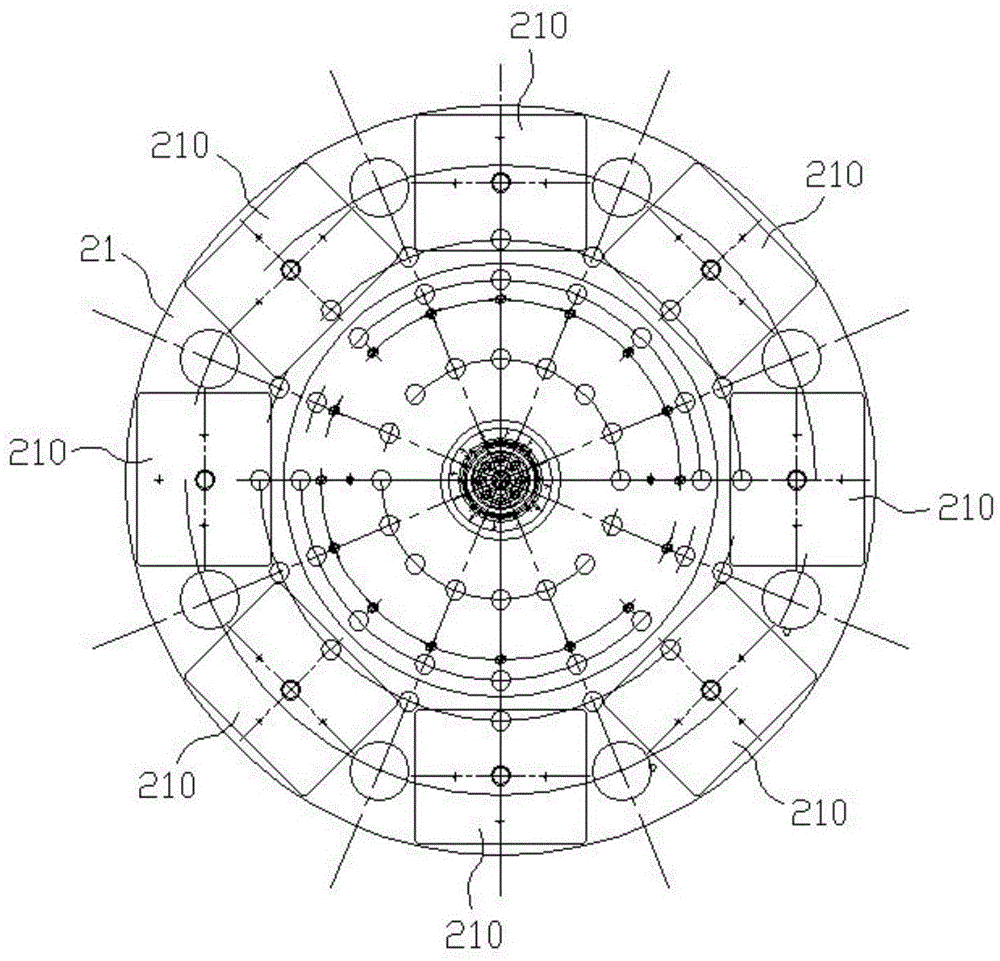

[0042] combine figure 1 , figure 2 , image 3 , the product transfer device 20 includes a turntable 21, a drive shaft 22 installed at the center of the turntable 21, the drive shaft 22 is connected to the motor, the drive shaft 22 is pivotally connected to the frame 10, and the turntable 21 is horizontal It is provided that eight backlight module stations 210 are arranged on the outer ring of the turntable 21 .

[0043] combine Figure 9 , Figure 10 , Figure 11 , the dust removal device 30 includes a bracket 310 , a casing 320 , an air outlet component 330 , a blower, and a cylinder 340 . The housing 320 is fixed on the bracket 310, the bracket 310 is installed on the frame 10, the housing 320 is in the shape of a cuboi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com