Automatic blank taking and arraying and tray filling machine for press and implementation method of automatic blank taking and arraying and tray filling machine

A technology of tray loading machine and press machine, which is applied in the direction of conveyor objects, transportation and packaging, grinding/polishing safety devices, etc. It can solve the problems of no automatic equipment, low product qualification rate, and low production efficiency, and achieve production efficiency High, improve the product qualification rate, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

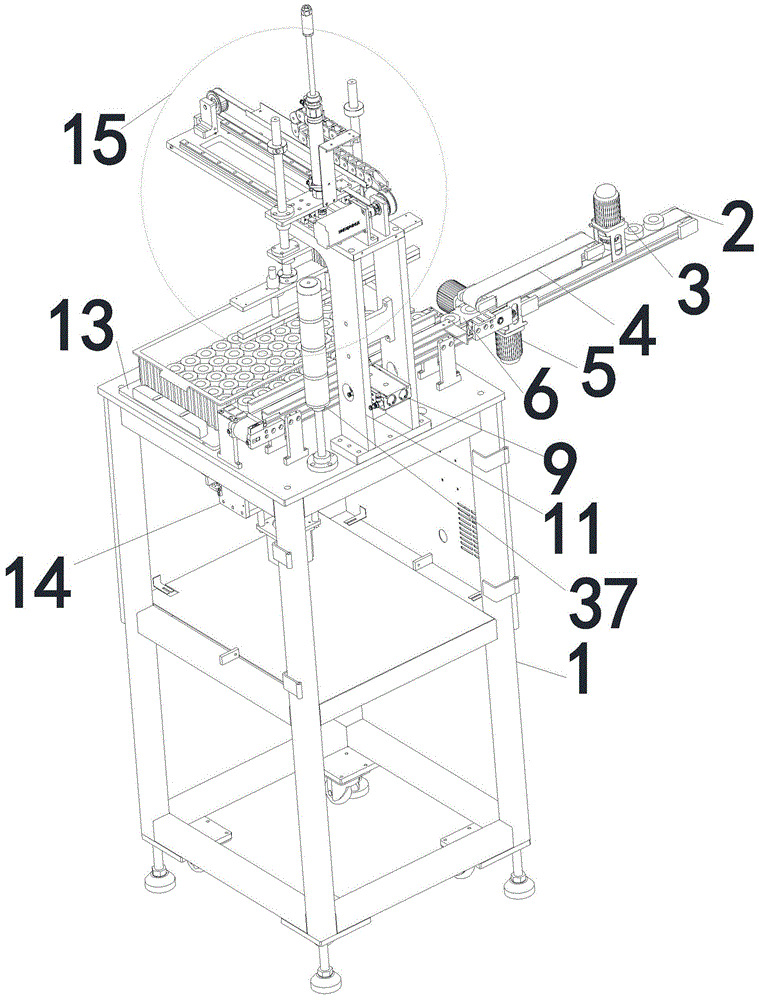

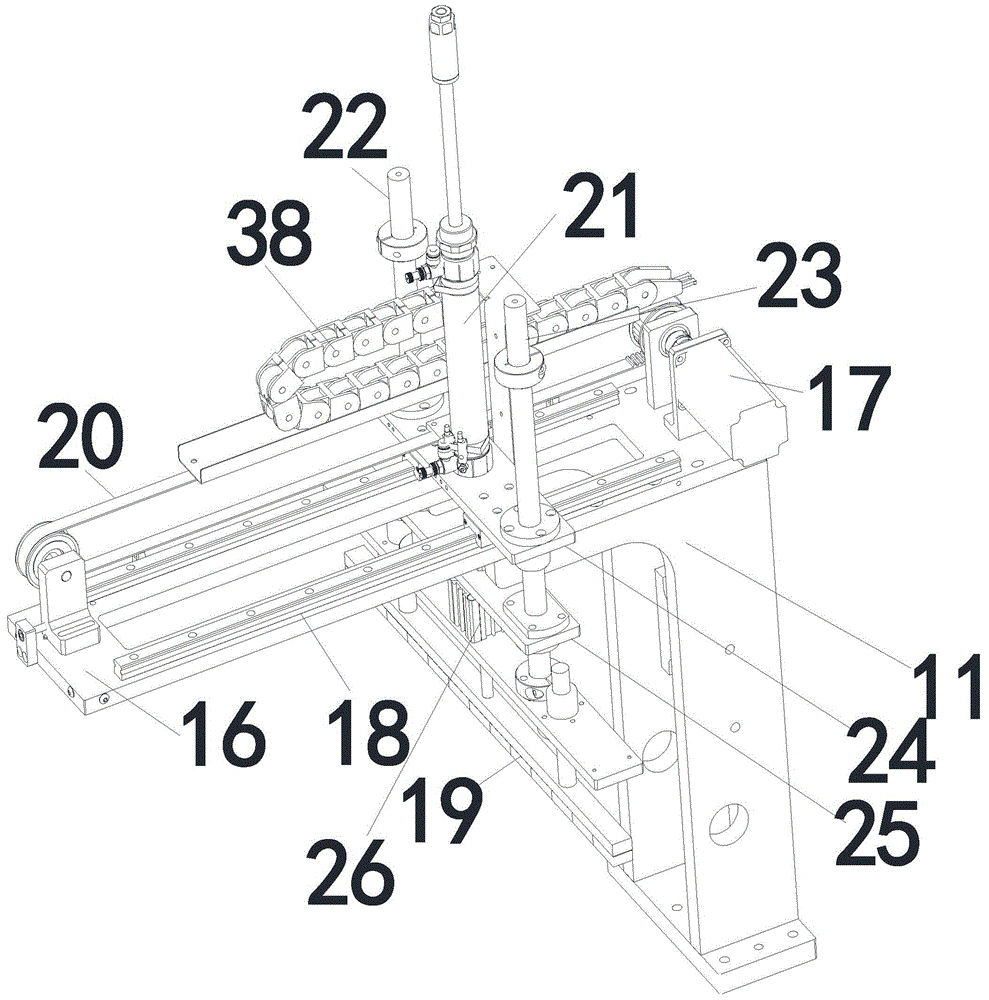

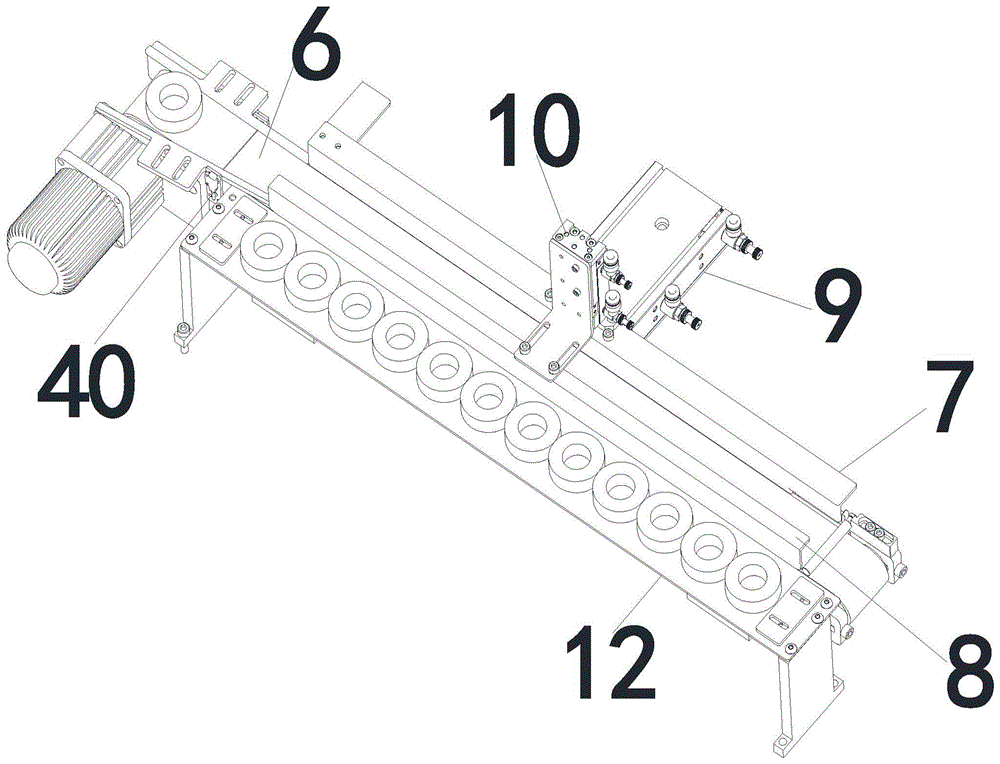

[0039] Such as Figure 1 to Figure 5As shown in the figure, a machine for automatically removing and arranging blanks for a press includes a frame 1, a first conveyor belt 2 is arranged on one side of the frame 1, and a top brush 3 and a second conveyor belt 2 are sequentially arranged above the first conveyor belt 2. Belt 4, the lower surface of the support bottom of the second conveyor belt 4 is provided with some magnets (not shown), the bottom brush 5 is arranged below the second conveyor belt 4, and the outlet end of the second conveyor belt 4 is the third conveyor belt 6, Such as image 3 As shown, the first regularizing strip 7 and the second regularizing strip 8 are arranged on both sides of the third conveyor belt 6, the first regularizing strip 7 is connected with the horizontal regularizing cylinder 9, the second regularizing strip 9 is connected with the vertical regularizing cylinder 10, and the horizontal regularizing cylinder 9 and the vertical regularizing cyl...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that this embodiment also includes a controller, and the controller is connected with the horizontal regularizing cylinder 9, the vertical regularizing cylinder 10, the motor 17, the lifting cylinder 21, the suction head cylinder 26, and the tray detection sensor respectively. 39. The billet feeding sensor 40, the first sensor for billet removal, the reset sensor for billet removal, the second sensor for billet removal, the first pallet sensor 34, the pallet reset sensor 36 and the pallet second sensor 35 are connected; the pallet detection sensor 39 It is arranged on the side of the rectangular plate, the billet feeding sensor 40 is arranged on the side of the entrance end of the third conveyor belt 6, the first sensor for taking and arranging blanks, the reset sensor for taking and arranging blanks, and the second sensor for taking and arranging blanks are respectively arranged on the linear slide rail in sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com