A detection unit of a web die-cutting machine with an online negative pressure suction conveying device

A negative pressure suction and detection unit technology, applied in transportation and packaging, cleaning methods using gas flow, object supply, etc., can solve problems such as belt bending deformation, detection false alarms, and belt negative pressure unevenness, to ensure No deformation, easy maintenance, and the effect of improving the range of adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

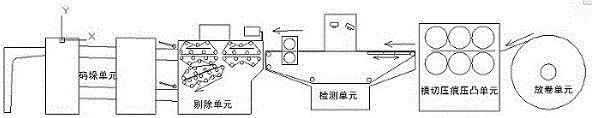

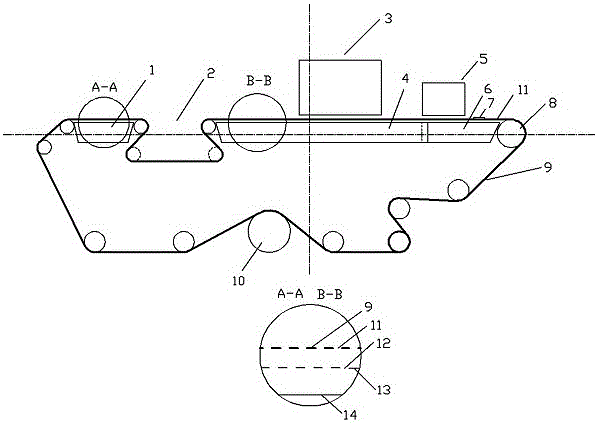

[0053] A detection unit with a negative pressure suction device for a web die-cutting machine, such as figure 2 As shown, the conveying belt 9 is driven by the active conveying roller 10 and several conveying roller shafts 8 installed on the frame, and the product 7 is sent to the detection and identification system 3 under the action of the conveying belt 9 .

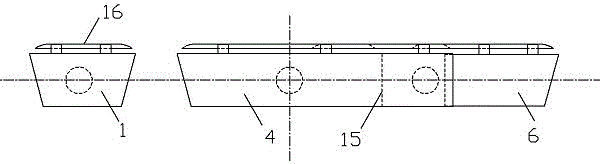

[0054] Such as Figure 2 ~ Figure 6 As shown, many conveying roller shafts 8 are horizontally installed on the frame, and a conveying belt 9 is laid on the conveying roller shaft 8. The conveying belt 9 is wide and full of small holes. Attached to the surface of the conveyor belt 9, the conveyor belt 9 is driven by the rotation of the conveyor roller shaft 8, and then the conveyor belt 9 drives the product 7 to move forward; a negative pressure cavity box 4 and a foldable negative pressure cavity box are arranged under the conveyor belt 9 6. Both are composed of the bottom plate 14 and the surrounding wall panels, an...

Embodiment 2

[0056] A detection unit with a negative pressure suction device for a web die-cutting machine, such as figure 2 As shown, the conveying belt 9 is driven by the active conveying roller 10 and several conveying roller shafts 8 installed on the frame, and the dust-removing product 7 passes through the online dedusting device 5 installed on the frame under the action of the conveying belt 9 Dust removal, the product after dust removal is identified by the detection and identification system 3, and enters the next process.

[0057] Such as Figure 7 ~ Figure 8 As shown, several conveying roller shafts 8 are horizontally installed on the frame, and a wide-format and small-hole conveying belt 9 is laid on the conveying roller shaft 8, and the conveying roller shaft 8 rotates to drive the conveying belt 9 to move forward. , the product 7 to be dedusted moves forward under the drive of the conveyor belt 9 .

[0058] Such as Figure 8 As shown, a first shaft 24 is installed in the i...

Embodiment 3

[0061] A detection unit with a negative pressure suction device for a web die-cutting machine, such as figure 2 As shown, the conveying belt 9 is driven by the active conveying roller 10 and several conveying roller shafts 8 installed on the frame 35, and the product 7 to be connected is dedusted by the online dedusting device 5 under the action of the conveying belt 9, and the dedusted product The product 7 is then identified by the detection and identification system 3, and enters the online connecting device 2 for connecting.

[0062] Such as Figure 9 , Figure 10Shown, upper roller shaft 40, lower roller shaft 45 are installed on frame 35, on upper roller shaft 40 and lower roller shaft 45, be respectively fixed with a string of upper roller 37 and lower roller 36 corresponding to each other, on upper roller 37 The surface and the surface of the lower roller 36 are provided with rectangular grooves; the positions of the rectangular grooves on the surface of the upper a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com