Steel plate hoisting device

A hoisting device and steel plate technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of time-consuming and laborious, small steel plate gaps, difficult to insert the spreader, etc., to ensure personal safety, work smoothly, and save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

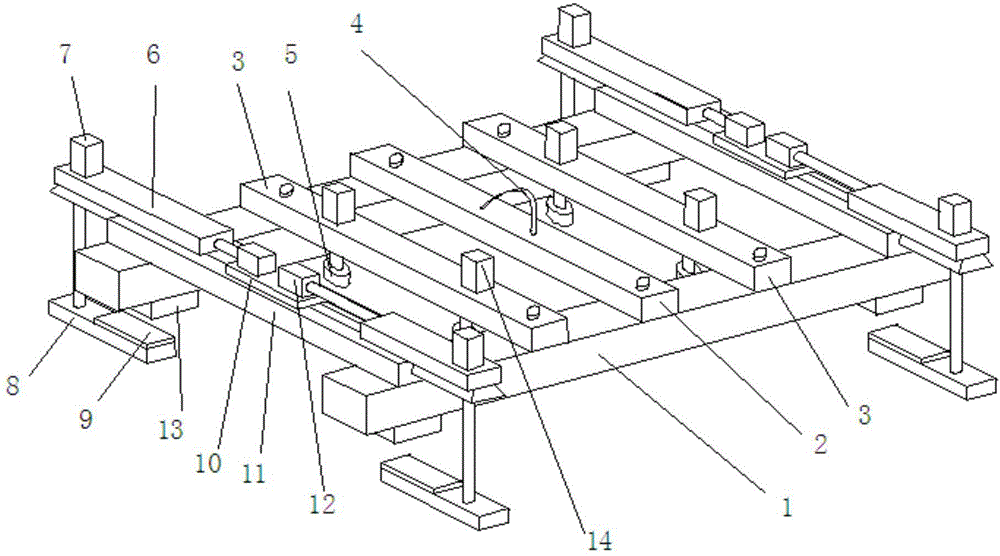

[0027] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

[0028] like figure 1 As shown, a steel plate hoisting device includes two lifting beams 1 and a pressing mechanism, a suction mechanism and a lifting mechanism provided on the two lifting beams 1, and the lifting beams 1 are arranged horizontally and in parallel;

[0029] The pressing mechanism includes a first beam 11 and two pressing units, the first beam 11 is fixedly arranged on the lifting beam 1, and the two pressing units are symmetrically arranged on the first beam 11, the The pressing unit includes a first hydraulic cylinder 12, a second hydraulic cylinder 7, a base 10, a support plate 6 and a pressing plate 8, and the upper surface of the first beam 11 is provided with a chute along the length direction of the first beam 11, and the base The seat 10 is fixed on the middle part of the first beam 11, the first hydraulic cylinder 12 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com