Hook assembly pulley installation structure

A technology of installation structure and hook group, which is applied in the direction of hoisting device, transportation and packaging, clockwork mechanism, etc., can solve the problems of shortened life of wire rope, affecting lifting safety, easy brackets, etc., to prolong service life and reduce cost Economical, wear-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

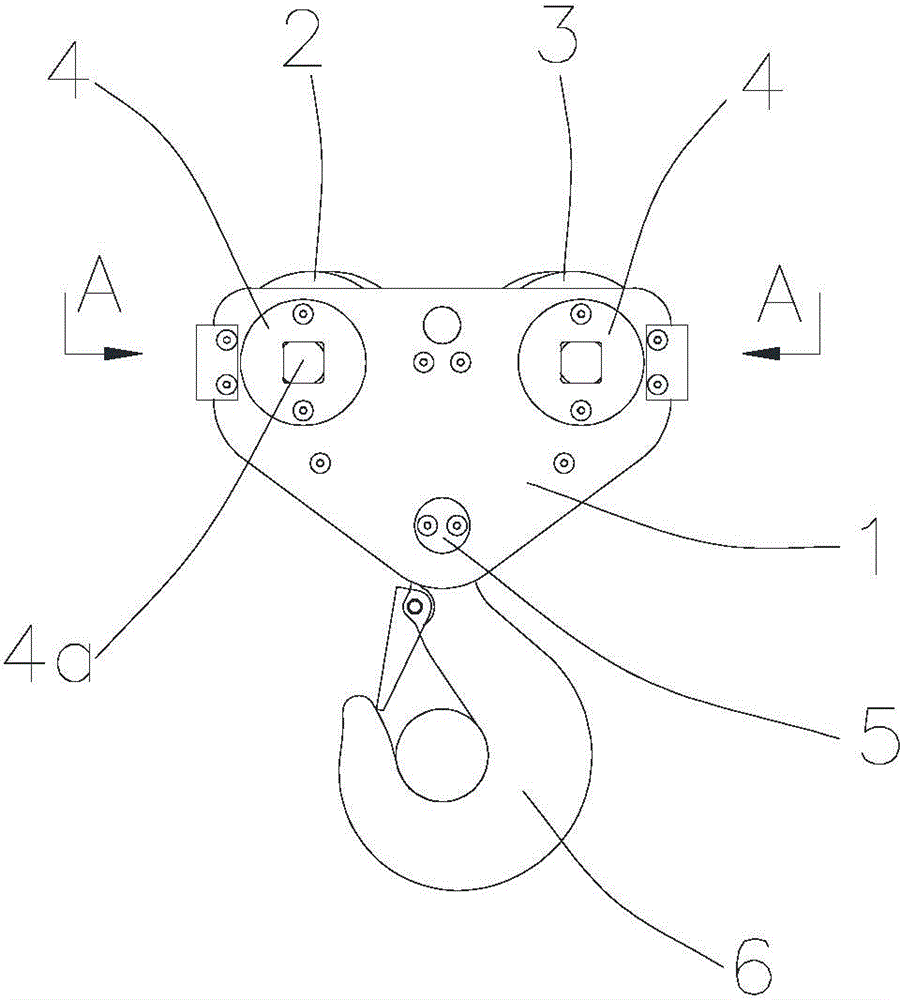

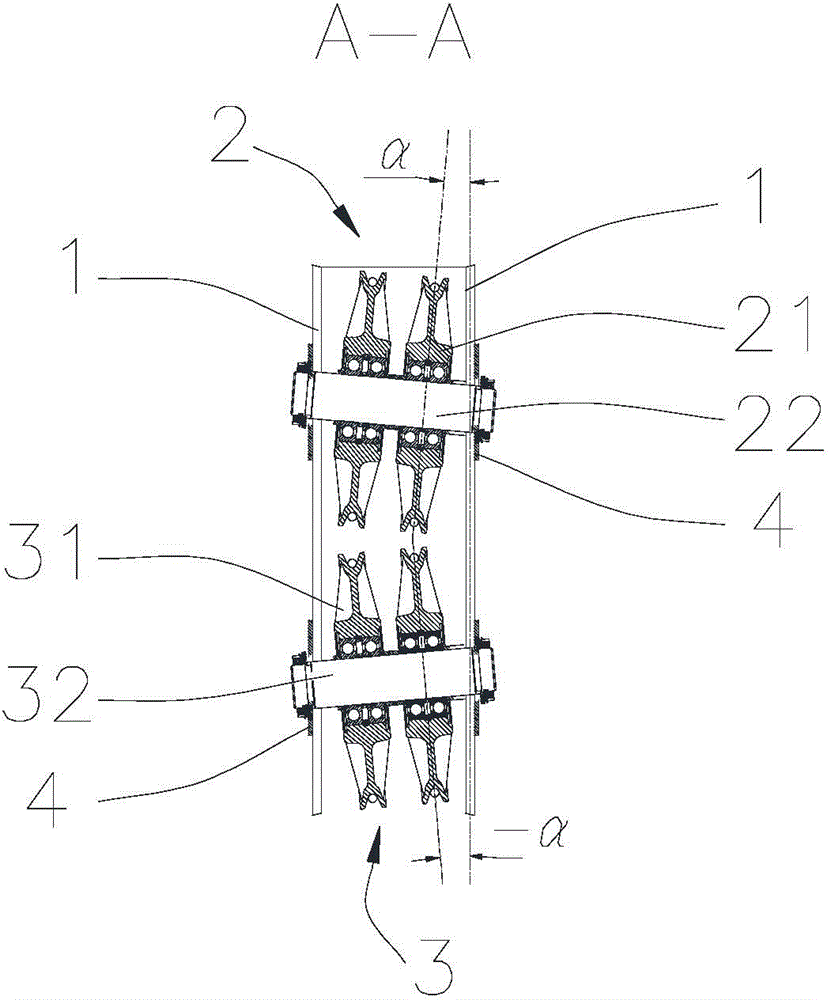

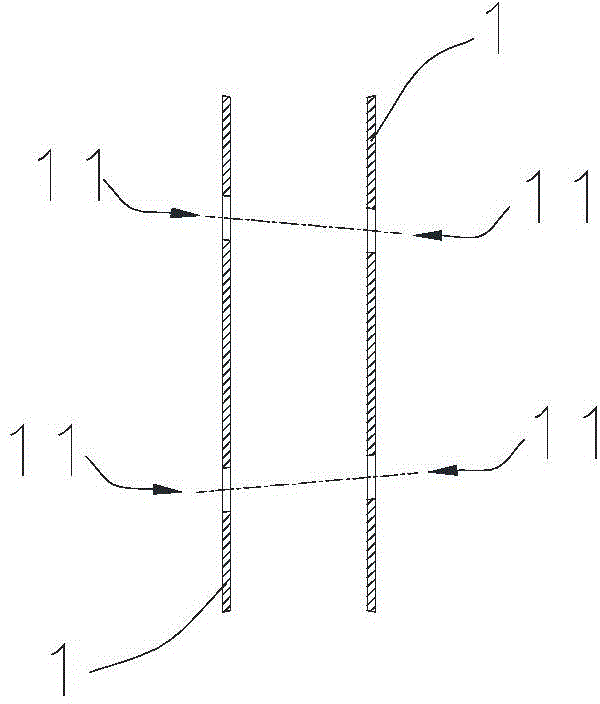

[0023] Such as Figure 1 to Figure 4 The shown hook block pulley installation structure includes two oppositely arranged side plates 1 and a first pulley block 2 and a second pulley block 3 arranged between the two side plates 1, the side plates 1 are vertically arranged, and the two sides The plates 1 are connected and fixed at three points by the first pulley shaft 22, the second pulley shaft 32 and the horizontal shaft 5 of the hook. The wheel shaft 22 is located on the same horizontal plane, and the hook horizontal shaft 5 is located below the horizontal plane where the first pulley shaft 22 and the second pulley shaft 32 are located. The middle part of the horizontal shaft 5 is provided with a suspension hook 6 through a bearing sleeve.

[0024] Depend on figure 2 It can be seen that the first pulley set 2 and the second pulley set 3 are mirror...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com