Microemulsion alumina red mud flocculant and preparation method thereof

A technology of alumina and microemulsion, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of easy clogging of conveying pipelines and filtration systems, reduction of effective active ingredients, Unsatisfactory use effect and other problems, to achieve the effect of convenient operation, fast dispersion speed and easy automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

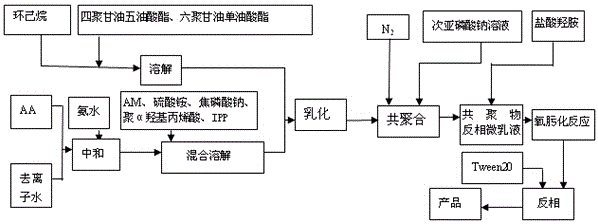

Method used

Image

Examples

Embodiment 1

[0046] Microemulsion alumina red mud flocculant and preparation method thereof

[0047] 1. Product formula of microemulsion alumina red mud flocculant:

[0048]

[0049] (1) Take 9.9 grams of deionized water and make sodium hypophosphite into a sodium hypophosphite solution with a concentration of 1wt% for use;

[0050] (2) Add the remaining 112.6 grams of deionized water into the polymerization reactor, add the measured acrylic acid (AA) under stirring (rotation speed: 200 rpm), control the temperature at 5-25°C, and slowly Add the measured ammonia water. After the ammonia water is added, add the measured acrylamide (AM), ammonium sulfate, sodium pyrophosphate, poly-α-hydroxyacrylic acid and diisopropyl peroxydicarbonate (IPP) in sequence until complete Dissolve and prepare the aqueous phase for later use;

[0051] (3) Add the measured cyclohexane, four polyglycerol pentaoleate, and six polyglycerol monooleate into the dissolving tank with stirring in turn, stir (the spe...

Embodiment 2

[0054] Microemulsion alumina red mud flocculant and preparation method thereof

[0055] 1. Product formula of microemulsion alumina red mud flocculant:

[0056]

[0057] 2. Preparation method of microemulsion alumina red mud flocculant:

[0058] (1) Take 14.85 grams of deionized water and make sodium hypophosphite into a sodium hypophosphite solution with a concentration of 1wt% for use;

[0059] (2) Add the remaining 86.15 grams of deionized water into the polymerization reactor, add the measured acrylic acid (AA) under stirring (rotation speed: 200 rpm), control the temperature at 5-25°C, and slowly Add the measured ammonia water. After the ammonia water is added, add the measured acrylamide (AM), ammonium sulfate, sodium pyrophosphate, poly-α-hydroxyacrylic acid and diisopropyl peroxydicarbonate (IPP) in sequence until complete Dissolve and prepare the aqueous phase for later use;

[0060] (3) Add the measured cyclohexane, four polyglycerol pentaoleate, and six polygl...

Embodiment 3

[0063] Microemulsion alumina red mud flocculant and preparation method thereof

[0064] 1. Product formula of microemulsion alumina red mud flocculant:

[0065]

[0066] 2. Preparation method of microemulsion alumina red mud flocculant:

[0067] (1) Take 20 grams of deionized water and make sodium hypophosphite into a sodium hypophosphite solution with a concentration of 1wt% for use;

[0068] (2) Add the remaining 48 grams of deionized water into the polymerization reactor, add the measured acrylic acid (AA) under stirring (60 rpm), cool down to below 15°C, and slowly add the measured Ammonia, the temperature of the reaction solution is controlled at 5-25°C. After the ammonia water is added, add the measured acrylamide (AM), ammonium sulfate, sodium pyrophosphate, poly-α-hydroxyacrylic acid and diisopropyl peroxydicarbonate (IPP) in sequence until completely dissolved, and prepare the water phase stand-by;

[0069] (3) Add the measured cyclohexane, four polyglycerol pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com