A kind of environment-friendly saturated polyester resin and preparation method thereof

A polyester resin, environmentally friendly technology, applied in the field of nail polish processing, environmentally friendly saturated polyester resin and its preparation, can solve the problems of environmental hazards, nail polish smell bad, unhealthy human body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

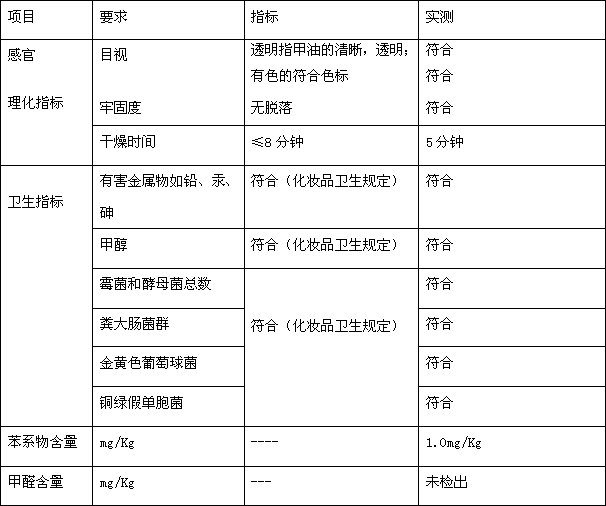

Examples

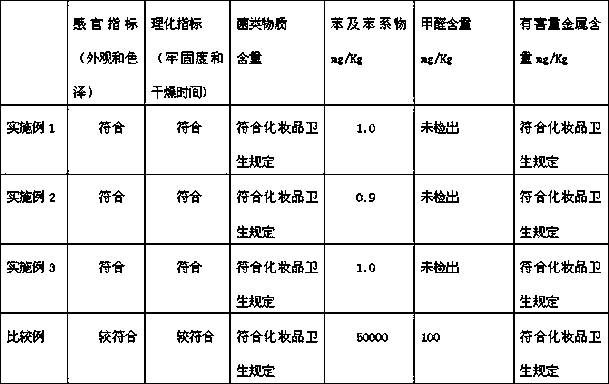

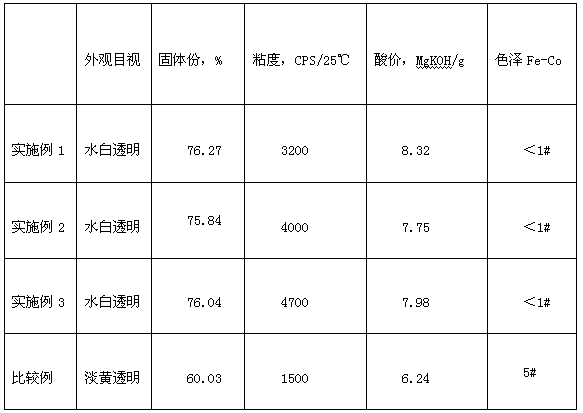

Embodiment 1

[0031] A kind of environment-friendly saturated polyester resin of the present embodiment comprises following raw material:

[0032] Neopentyl glycol (flexible raw material) 27.4 grams, trimethylolpropane 2.6 grams, adipic acid (flexible raw material) 14.5 grams, isophthalic acid 5.6 grams, phthalic anhydride 5.6 grams, trimellitic anhydride 7.0 grams, maleic anhydride 2.1 gram, antioxidant (triphenyl phosphite) 0.17 gram, n-butyl acetate (reflux agent) 2.1 grams, n-butyl acetate (diluent) 18 grams.

[0033] The environment-friendly saturated polyester resin operating process of the present embodiment is as follows:

[0034] 1) Add 27.4 grams of neopentyl glycol, 2.6 grams of trimethylolpropane, 14.5 grams of adipic acid, 5.6 grams of isophthalic acid, 5.6 grams of phthalic anhydride, 7.0 grams of trimellitic anhydride, Put 2.1 grams of maleic anhydride and 0.17 grams of antioxidant (triphenyl phosphite) into the reactor, feed nitrogen into the reactor and slowly raise the te...

Embodiment 2

[0039] A kind of environmental protection saturated polyester resin of the present embodiment comprises following raw material:

[0040] 32.3 grams of neopentyl glycol, 3.1 grams of trimethylolpropane, 17.1 grams of adipic acid, 6.6 grams of isophthalic acid, 6.6 grams of phthalic anhydride, 8.2 grams of trimellitic anhydride, 2.5 grams of maleic anhydride, antioxidant (phosphorous acid Triphenyl ester) 0.21 grams, n-butyl acetate (reflux) 2.5 grams, diluent n-butyl acetate 21 grams;

[0041] The resin operating process of the present embodiment is as follows:

[0042]1) Add in a clean and dedicated reactor: 32.3 grams of neopentyl glycol, 3.1 grams of trimethylolpropane, 17.1 grams of adipic acid, 6.6 grams of isophthalic acid, 6.6 grams of phthalic anhydride, and 8.2 grams of trimellitic anhydride , 2.5 grams of maleic anhydride, 0.21 grams of antioxidant (triphenyl phosphite) into the reactor, feed nitrogen into the reactor and slowly heat up the reactor at a rate of 10°C / ...

Embodiment 3

[0047] A kind of environment-friendly saturated polyester resin of the present embodiment comprises following raw material: 37.1 grams of neopentyl glycol, 3.6 grams of trimethylolpropane, 19.7 grams of adipic acid, 7.6 grams of isophthalic acid, 7.6 grams of phthalic anhydride gram, trimellitic anhydride 9.5 grams, maleic anhydride 2.9 grams, antioxidant (triphenyl phosphite) 0.25 grams, n-butyl acetate (reflux) 2.9 grams, diluent n-butyl acetate 24 grams.

[0048] The resin operating process of the present embodiment is as follows:

[0049] 1) Add in a clean and dedicated reactor: 37.1 grams of neopentyl glycol, 3.6 grams of trimethylolpropane, 19.7 grams of adipic acid, 7.6 grams of isophthalic acid, 7.6 grams of phthalic anhydride, and 9.5 grams of trimellitic anhydride , 2.9 grams of maleic anhydride, 0.25 grams of antioxidant (triphenyl phosphite) into the reaction kettle, feed nitrogen into the reaction kettle and raise the temperature of the reaction kettle, start to h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com