A kind of preparation method of high temperature resistant alloy die steel

A technology of high temperature resistant alloy and die steel, applied in the field of die materials, can solve the problems of low strength and high heat resistance, and achieve the effect of good internal toughness and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

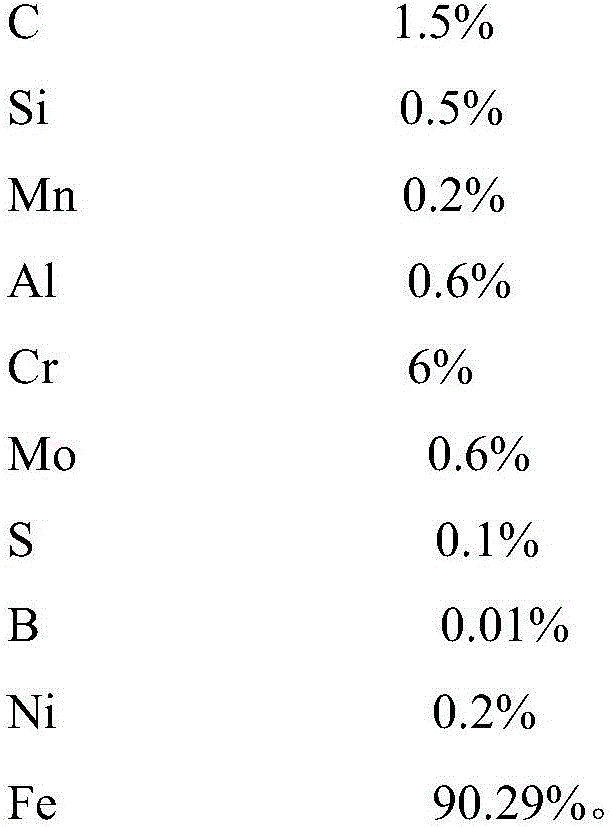

[0025] A kind of high temperature resistant alloy die steel is characterized in that, described mass ratio is as follows,

[0026]

[0027] Using a certain amount of C can improve the shape and high temperature resistance strength just now in the billet stroke.

[0028] Si is added to ensure its stability during heat treatment and the strength of the steel slab, to ensure that it has good high-temperature strength and high-temperature hardness, and has good stability during heat treatment.

[0029] Mo is used to improve the hot strength of steel at high temperature. Instability caused by overheating of steel can be prevented.

[0030] The addition of Cr can make the alloy steel have oxidation resistance at high temperature, and its hot corrosion performance is greatly improved, and its combination with C can form a hard compound, making it have good wear resistance and toughness.

[0031] Using a certain amount of B can make the alloy steel have good internal ductility, w...

Embodiment 2

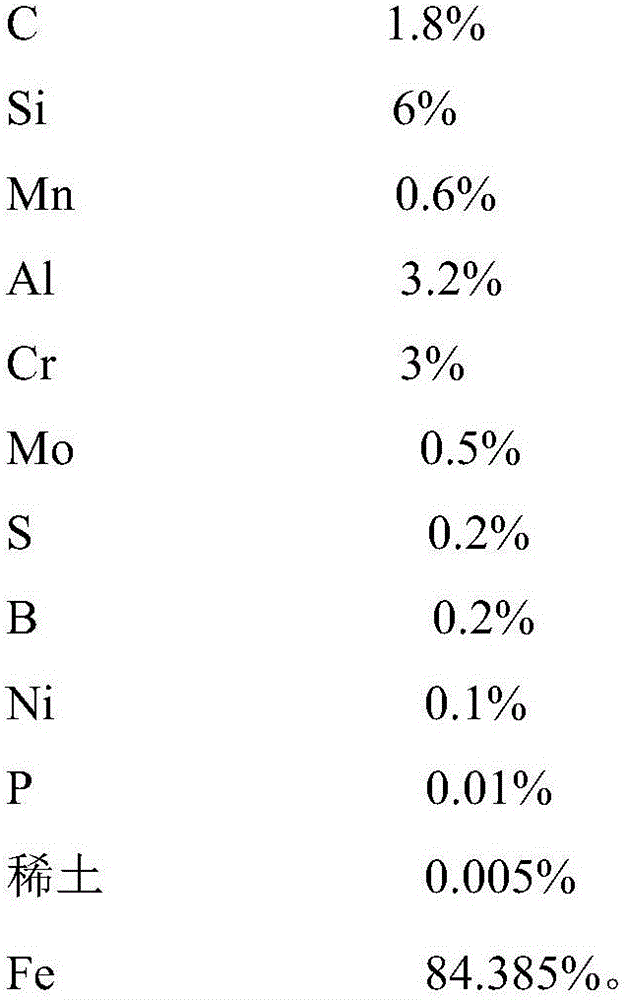

[0040] A kind of high temperature resistant alloy die steel is characterized in that, described mass ratio is as follows,

[0041]

[0042] The addition of P makes the alloy steel have better fatigue resistance and mechanical properties.

[0043] There is also a small amount of rare earth elements. Adding a certain amount of rare earth elements in the material can improve the oxidation resistance of the alloy, improve the expansion of fatigue cracks, and have a long service life and toughness.

[0044] A preparation method of high temperature resistant alloy die steel, the steps are as follows:

[0045] (A) Weigh C1.8%; Si6%; Mn0.6%; Al3.2%; Cr3%; Mo0.5%; S0.2%; B0.2%; Ni0.1%; P0.01% ; Rare earth 0.005%; Fe 83.385%;

[0046] (B) smelting the above-mentioned various raw materials, and hot rolling them into billets after smelting;

[0047] (C) Perform solid solution treatment on the billet obtained in the previous step: heat the billet to 1000-1100°C for 3-6 hours, and the...

Embodiment 3

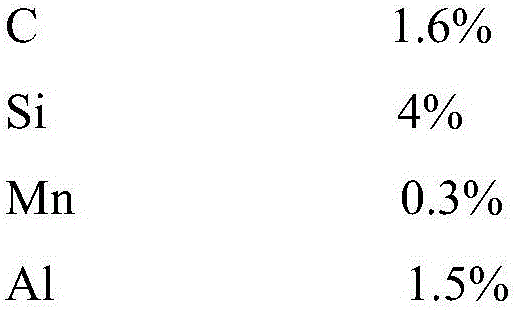

[0053] A kind of high temperature resistant alloy die steel is characterized in that, described mass ratio is as follows,

[0054]

[0055]

[0056] A preparation method of high temperature resistant alloy die steel, the steps are as follows:

[0057] (A) Weigh C1.6%; Si4%; Mn0.3%; Al1.5%; Cr5%; Mo0.5%; S0.2%; B0.1%; Ni0.1%; P0.02% ; Rare earth 0.005%; Fe 86.675%;

[0058] (B) smelting the above-mentioned various raw materials, and hot rolling them into billets after smelting;

[0059] (C) Carry out solid solution treatment to the billet obtained in the previous step: heat the billet to 1000-1100° C. for 3-6 hours, and cool it to room temperature with oil cooling. 300°C; during the heating process, set a heat preservation step at 880°C for 1 hour.

[0060] (D) carrying out quenching treatment to above-mentioned billet;

[0061] (E) Tempering: heat the billet obtained in the previous step to 700-710°C, keep it warm for 10 hours, and cool it down to room temperature by a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap