Roof greening structure

A roof greening and roof structure layer technology, which is applied in roof decoration, building roofs, roof insulation materials, etc., can solve the problems of loss of drainage function of the drainage layer, insufficient supply of nutrients for roof plant growth, and poor drainage congestion, etc., to achieve good results. Waterproof and puncture-proof performance, reduce the number of manual maintenance and cost, reduce the effect of weighing pressure and hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

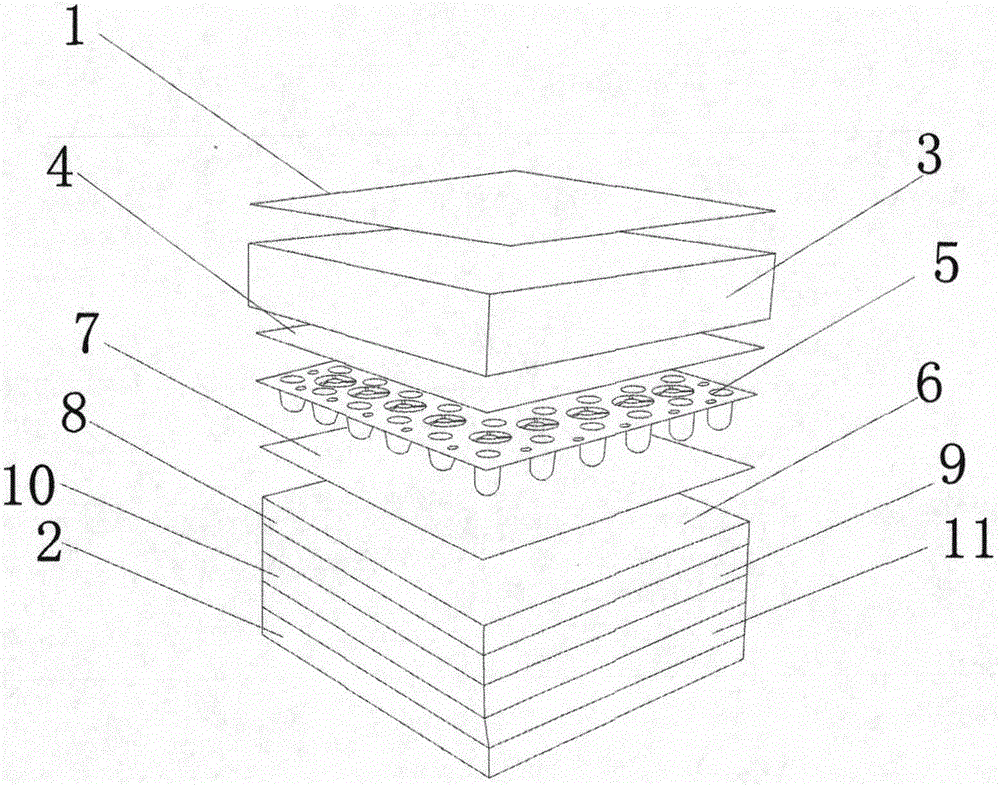

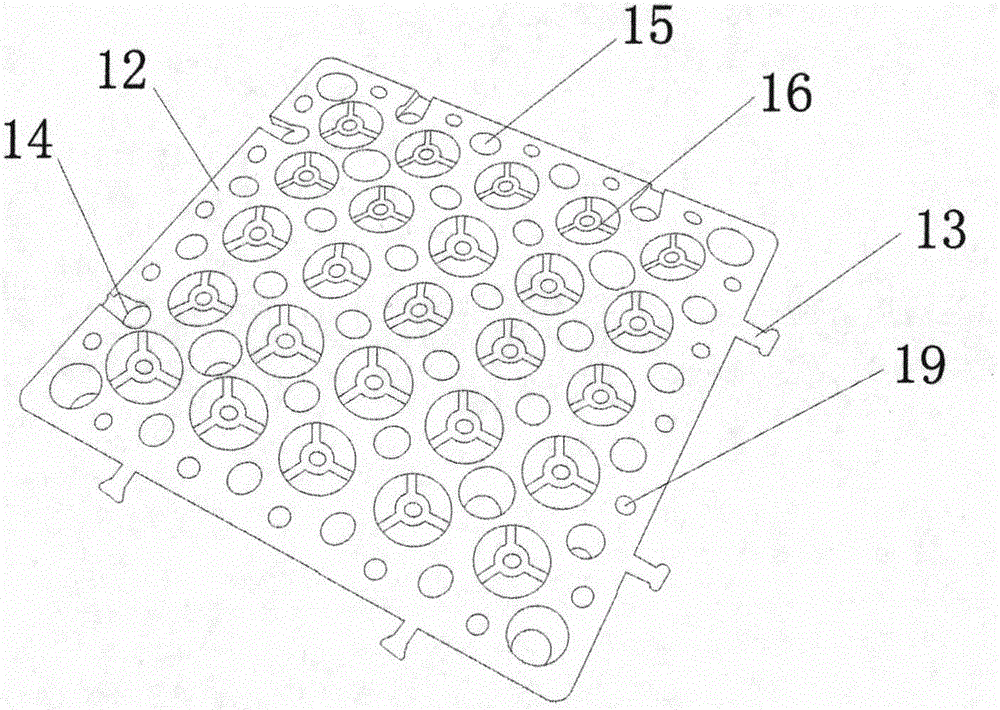

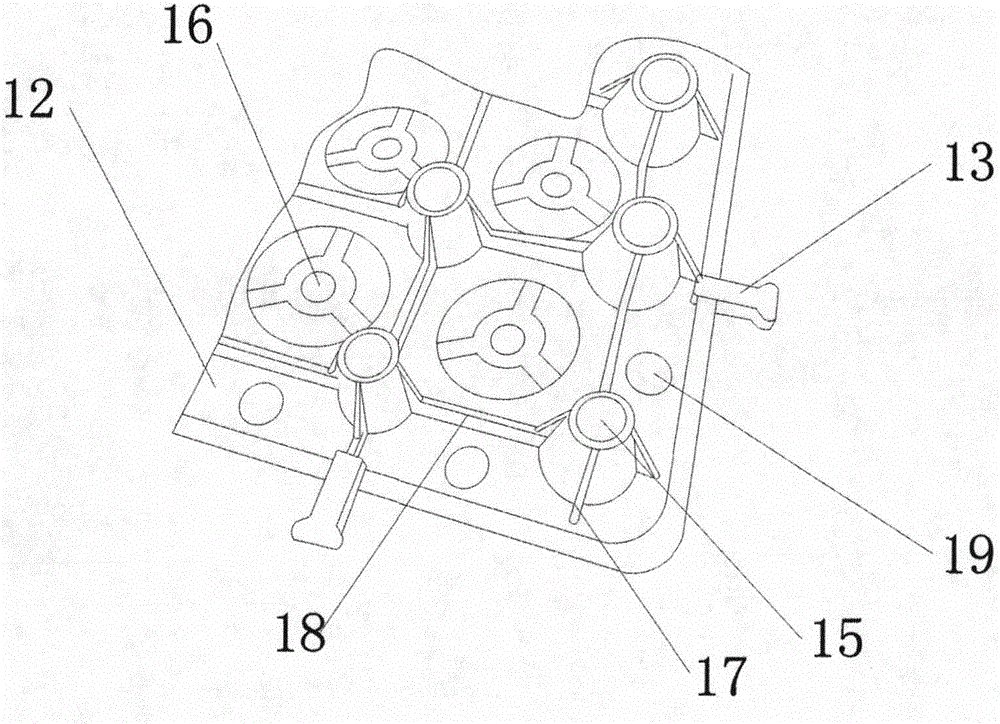

[0023] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0024] Such as figure 1 , 2 A kind of roof greening structure shown in .3 has a vegetation layer 1 and a roof structure layer 2, the roof structure layer 2 adopts cast-in-place reinforced concrete, the slab seam width is greater than 40mm, the slab end seams are embedded with sealing materials, and the bottom of the vegetation layer 1 A planting medium layer 3 is provided, and the lower end of the planting medium layer 3 is provided with an isolation filter layer 4. The isolation filter layer 4 is made of polyester fiber geotextile, and its weight is 200-300g / m 2 The lower end of the isolation filter layer 4 is provided with a drainage (storage) water layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com