Water spry cooling method and system of low-pressure exhaust hood of air-cooling steam turbine

A water spray cooling and exhaust cylinder technology, applied in the field of steam turbines, can solve problems such as water spray cooling failure of low pressure cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

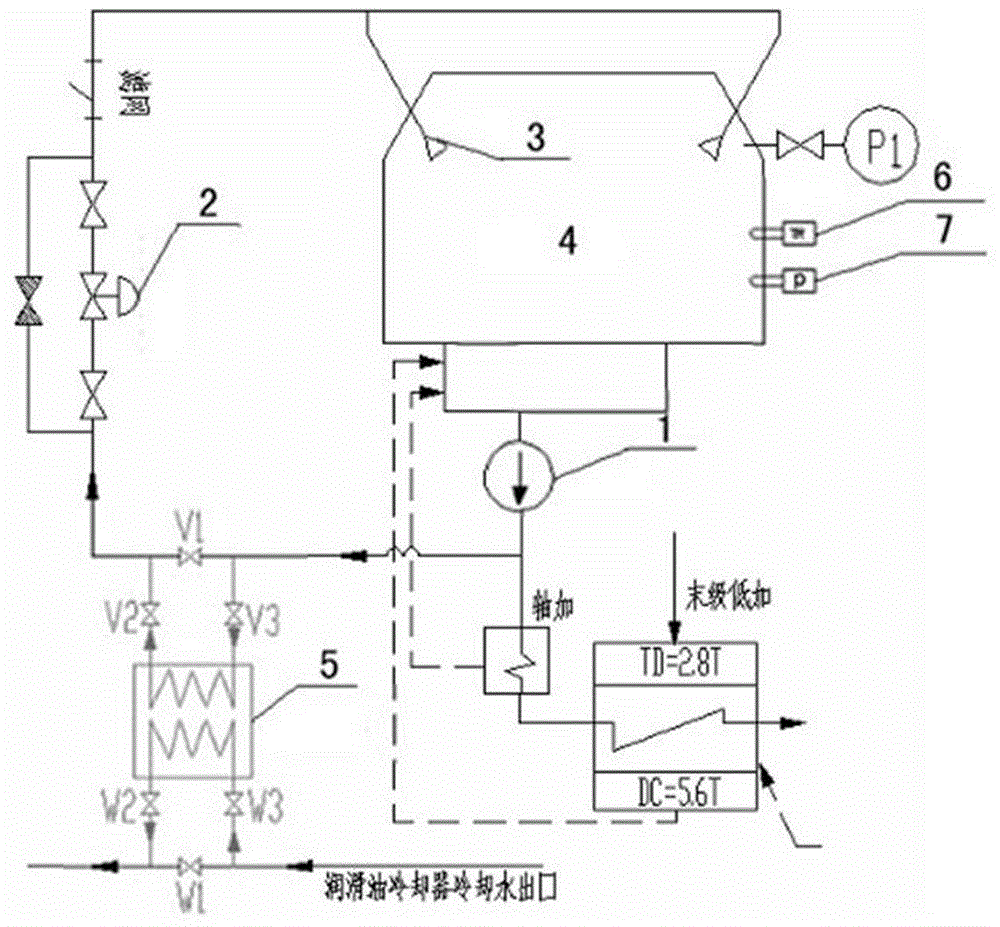

[0015] see figure 1 : This air-cooled steam turbine low-pressure exhaust cylinder water spray cooling system includes a condensate pump 1, a regulating valve 2, and a nozzle 3, which are sequentially connected through pipelines to form a water spray pipeline, and the condensate pump 1 extracts the condensate in the low-pressure exhaust cylinder 4. Regulating valve 2 regulates the flow of condensed water, and sprays the exhaust steam in low-pressure exhaust cylinder 4 through nozzle 3. Between condensed water pump 1 and regulating valve 2, there are two parallel water supply branches, one of which is a straight-through branch. The condensed water can be sent directly to the regulating valve 2, and the other one is equipped with a water / water heat exchanger 5, and the condensed water is cooled by the discharge water at the outlet of the lubricating oil cooler, and then the cooled condensed water is sent to the regulating valve 2, The two water supply branches are switched by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com